Dust control cover for a refuse bin

a technology for a refuse bin and a dust control cover, which is applied in the direction of lids, liquid handling, and refuse gathering, etc., can solve the problems of no knowledge or realization of the potential hazards of handling such materials, and the dust and particulate matter emission is notoriously high in building construction and demolition operations, so as to reduce or eliminate the emission of dust and particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

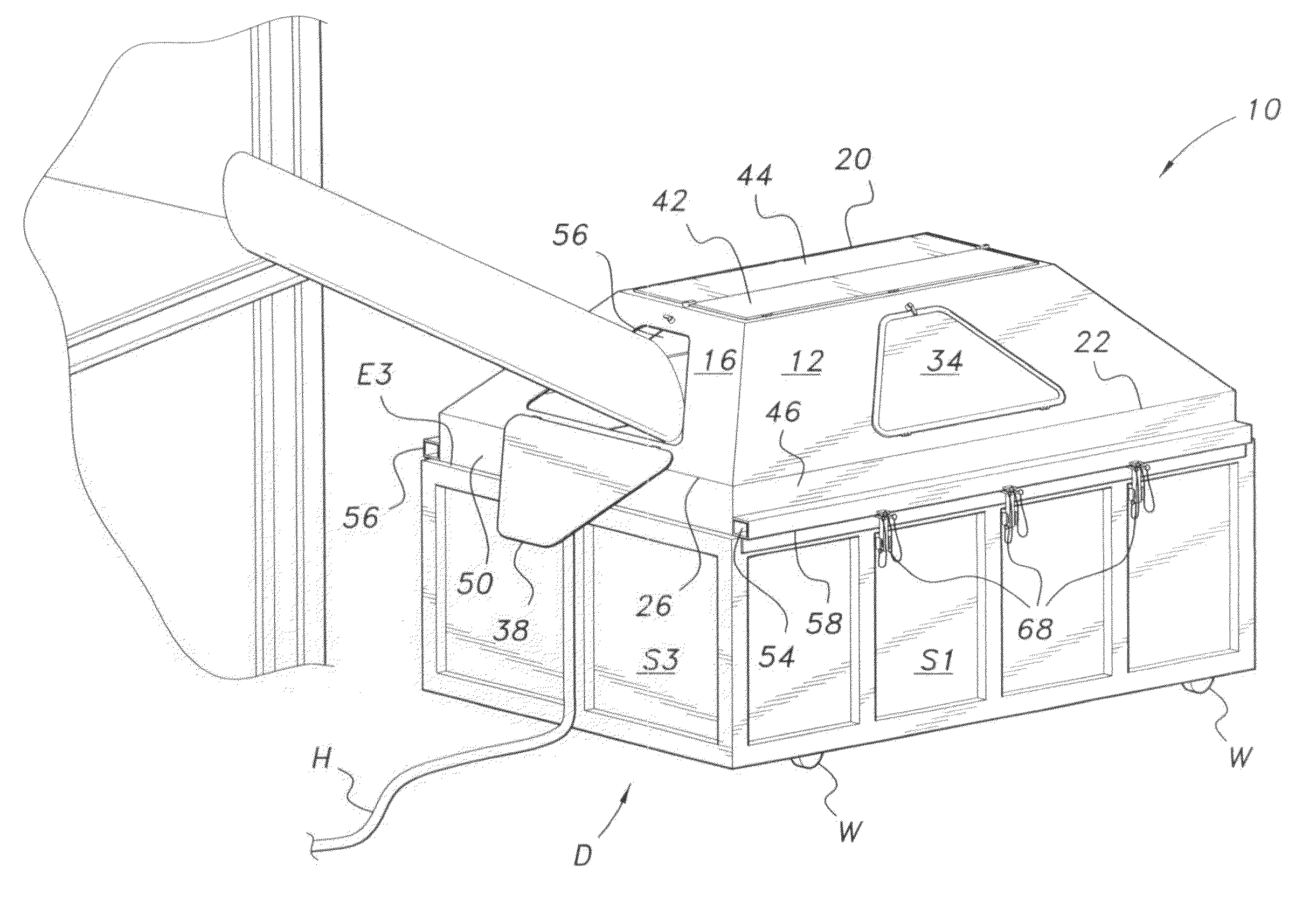

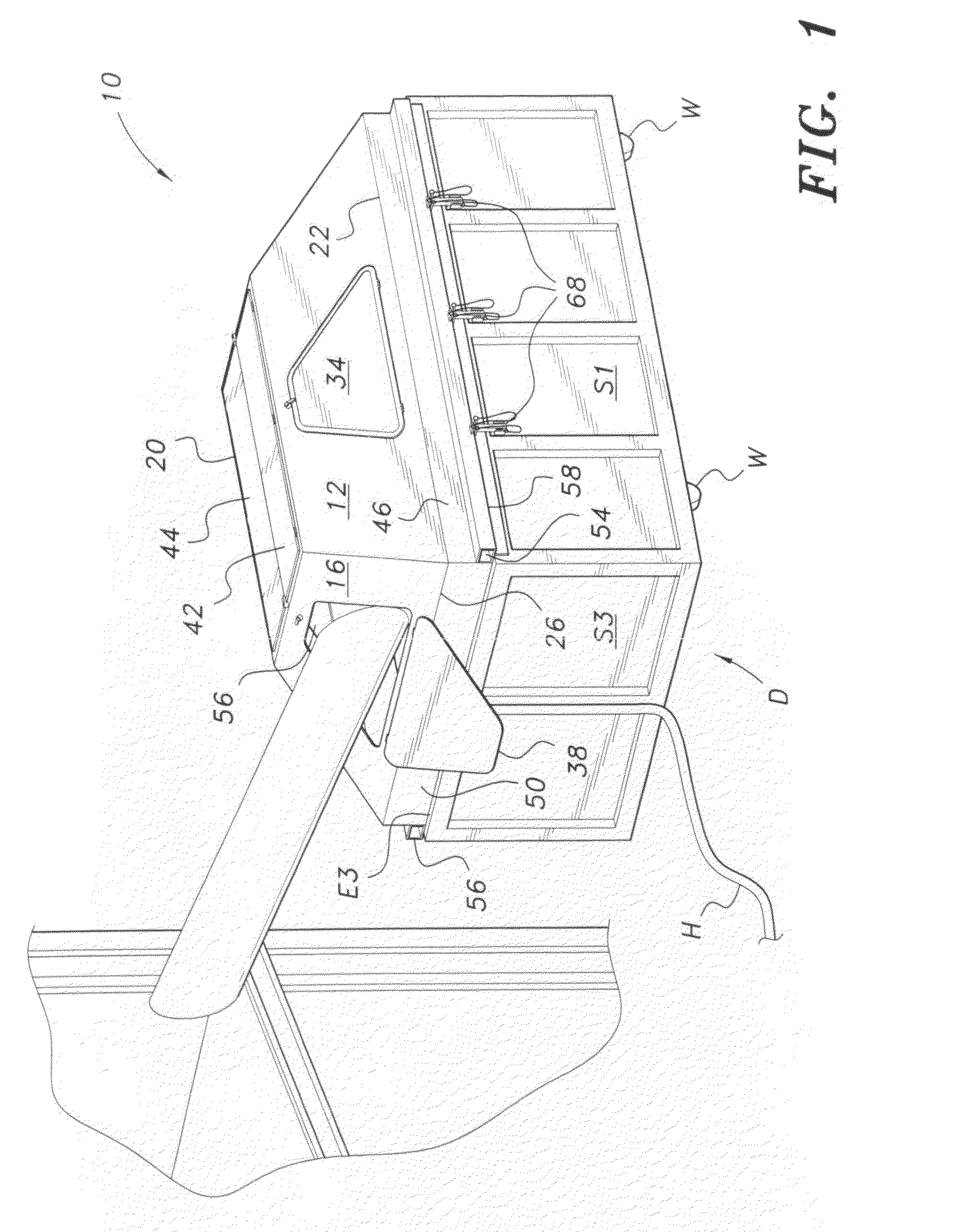

[0018]The dust control cover for a refuse bin may include a water system for reducing airborne dust, as well as a series of retaining pin assemblies to assure that the cover or lid remains positively attached to the underlying bin or dumpster during transport. FIG. 1 provides an environmental view of the dust control cover or lid 10 secured to the top of a refuse bin or dumpster D at a building construction or demolition site. The bin or dumpster D may be a roll-off type dumpster having wheels W, as shown in FIGS. 1 and 3, or other refuse bin type or configuration as desired.

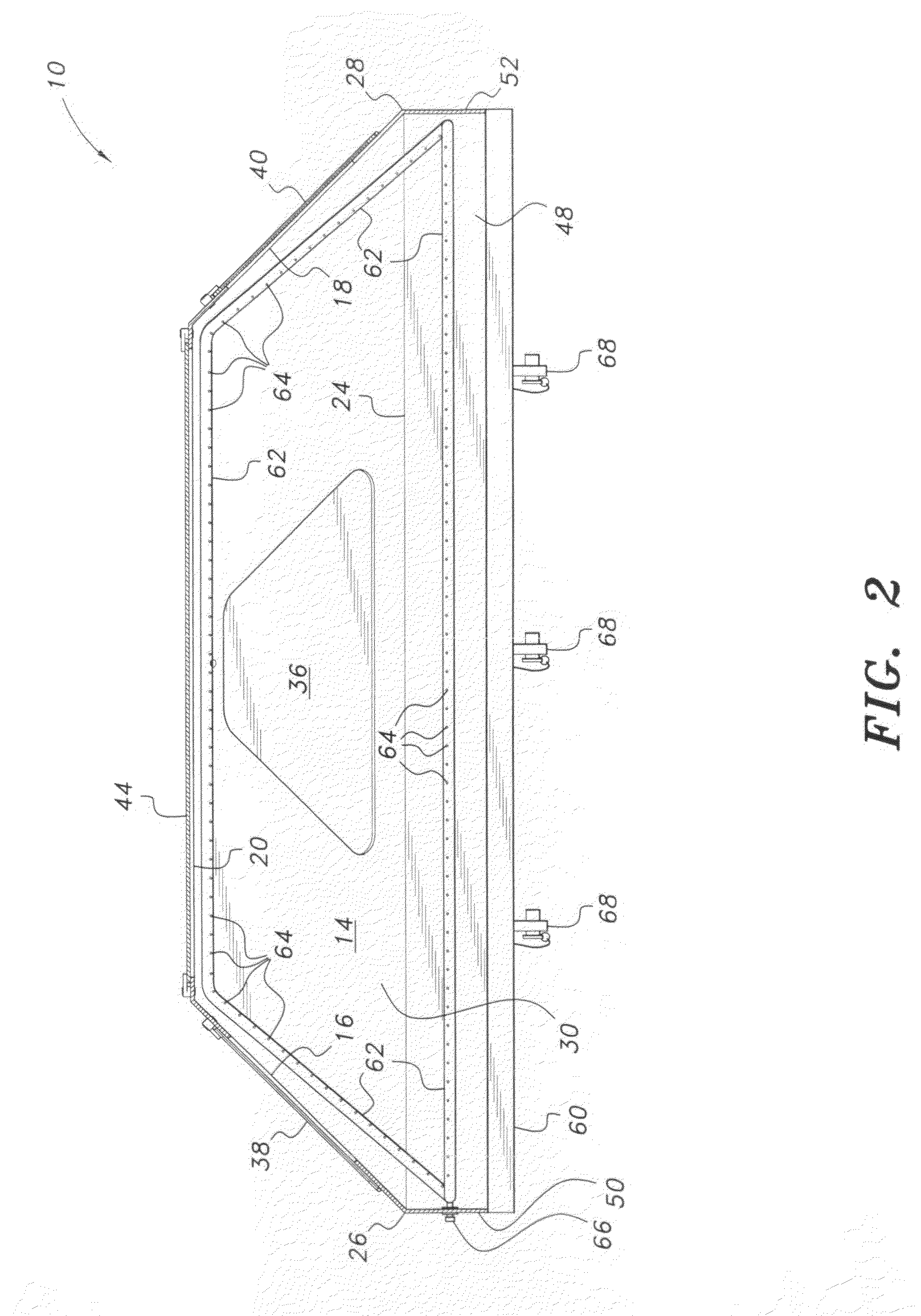

[0019]The dust control cover or lid 10 is in the general form or shape of an elongated and truncated pyramid, having opposite first and second major sides 12 and 14, opposite first and second minor sides or ends 16 and 18, and a flat top or apex 20; the second major side 14 and second minor side 18 are shown in the elevation view in section of FIG. 2. Each of the sides 12 through 18 has a lower edge, respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com