Joint and foldable structures employing the same

a foldable structure and joint technology, applied in the field of joints, can solve the problems of not being stackable compactable, not allowing a plurality of segments interconnected by such joints to stackably compact, etc., and achieve the effect of supporting significant weight and efficient compacting to a stowed configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

foldable table example

Application

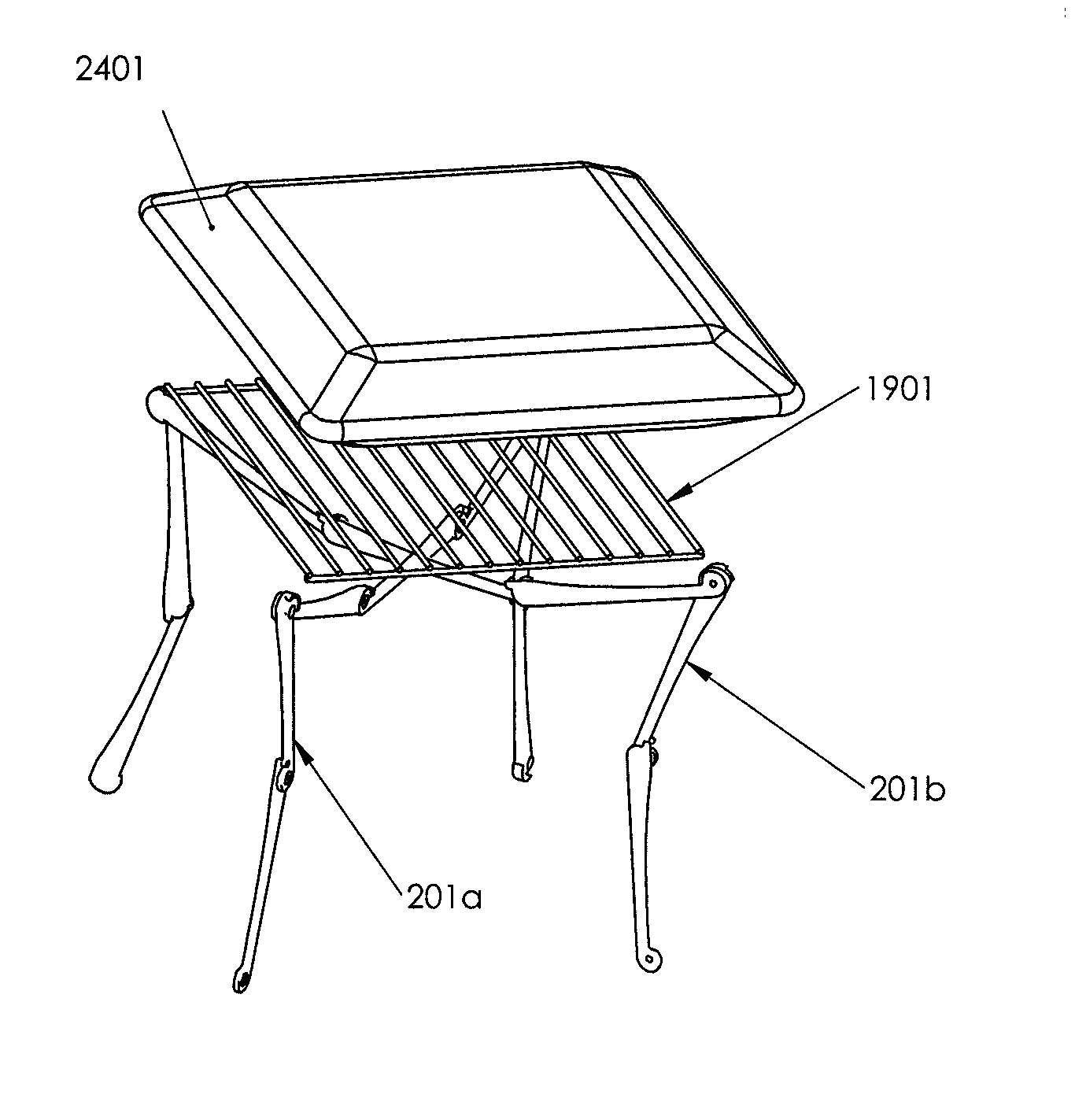

FIGS. 22a-22c illustrate another application of the foldable joint 101 mechanism, which is a table in this example application but a similar assembly may alternatively be applied to other types of furniture, such as sofas, nightstands, seating devices, as described below, and many others. The table example includes at least two foldable extensions 201a and 201b that intersect in approximately the center to form a support structure 1801 to which a table top 2201 is removably attached. Those of skill in the art will recognize that the support structure 1801 of the table is constructed similarly to that of the grill application described above. Similarly to the support structure 1801 of the grill, the foldable extensions 201a and 201b of the table interconnect through complementary assembly notches 1802, one on the bottom surface 305 of the first frame element 201b, and another on the top surface 304 of the second frame element. The foldable extensions of the support structu...

example application

Shovel Handle Example Application

FIG. 28a illustrates a foldable shovel that comprises at least one foldable extension to form the handle shaft 3202, removably attached to the shovel blade 3201 at one end and a handle grip 3203 at the other end. While the handle shaft 3202 may be formed out of one foldable extension 201, FIGS. 28b-28c illustrate how at least two foldable extensions 201j and 201k may be connected such that they fold in opposite directions and thus maintain one another in the extended configuration. FIG. 28d is a detailed view of how foldable extensions 201j and 201k may be interconnected and folded into a compact stowed configuration. The handle grip 3203 and shovel blade 3201 are detachable for shipping, storage, and user transportation. This doubling configuration may be employed in other types of handles or devices with elongated sections, such as fishing rods, ski poles, oars, swords, javelins, rackets, bats, basketball hoops, shelter frames poles, walkers, canes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com