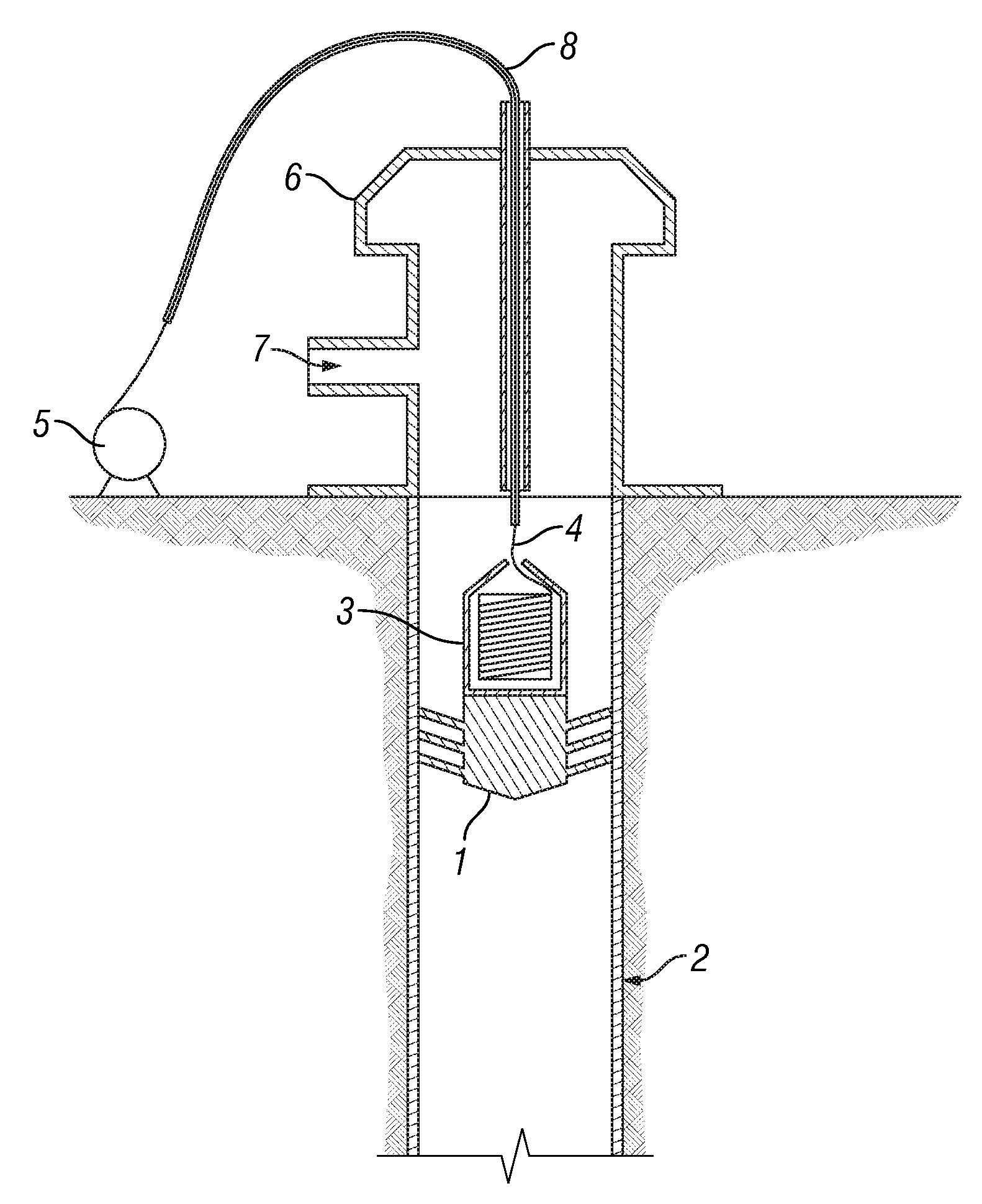

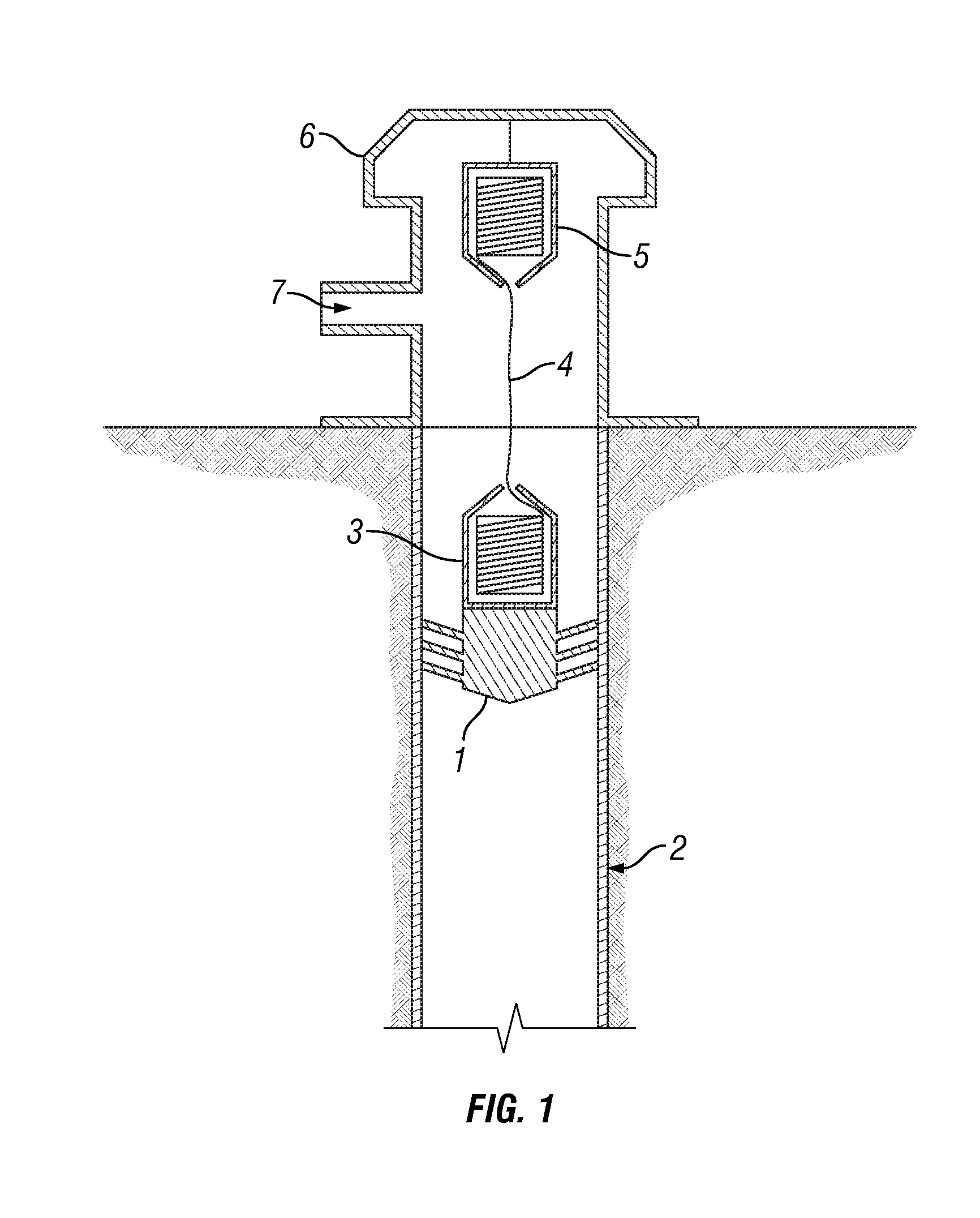

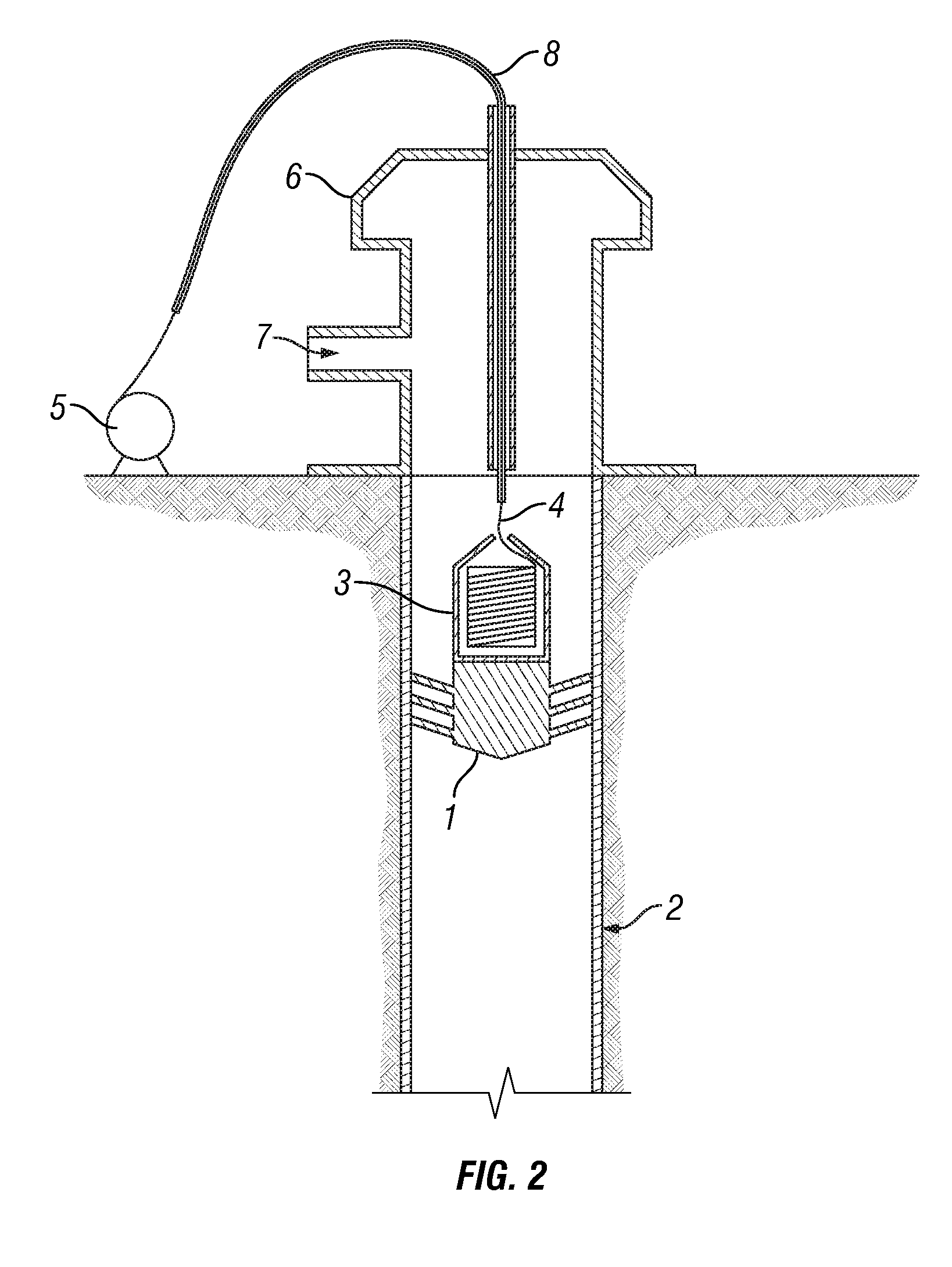

Equipment and Methods for Deploying Line in a Wellbore

a wellbore and equipment technology, applied in the direction of directional drilling, drilling holes/well accessories, sealing/packing, etc., can solve the problem that the line from the second reel may also be unwound, and achieve the effect of minimizing the stress on the lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The invention may be described in terms of treatment of vertical wells, but is equally applicable to wells of any orientation. The invention may be described for hydrocarbon production wells, but it is to be understood that the invention may be used for wells for production of other fluids, such as water or carbon dioxide or, for example, for injection or storage wells. This invention may be described for offshore and land wells. It should also be understood that throughout this specification, when a concentration or amount range is described as being useful, or suitable, or the like, it is intended that any and every concentration or amount within the range, including the end points, is to be considered as having been stated. Furthermore, each numerical value should be read once as modified by the term “about” (unless already expressly so modified) and then read again as not to be so modified unless otherwise stated in context. For example, “a range of from 1 to 10” is to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com