Internal Combustion Engine Control Device and Internal Combustion Engine Control System

a control device and control system technology, applied in the direction of machines/engines, non-mechanical valves, output power, etc., can solve the problems of difficult to ensure a good restartability, control device requires a comparatively long time duration, and the vtc mechanism exhibits a bad operational responsiveness at very low engine speed, so as to achieve good engine restartability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

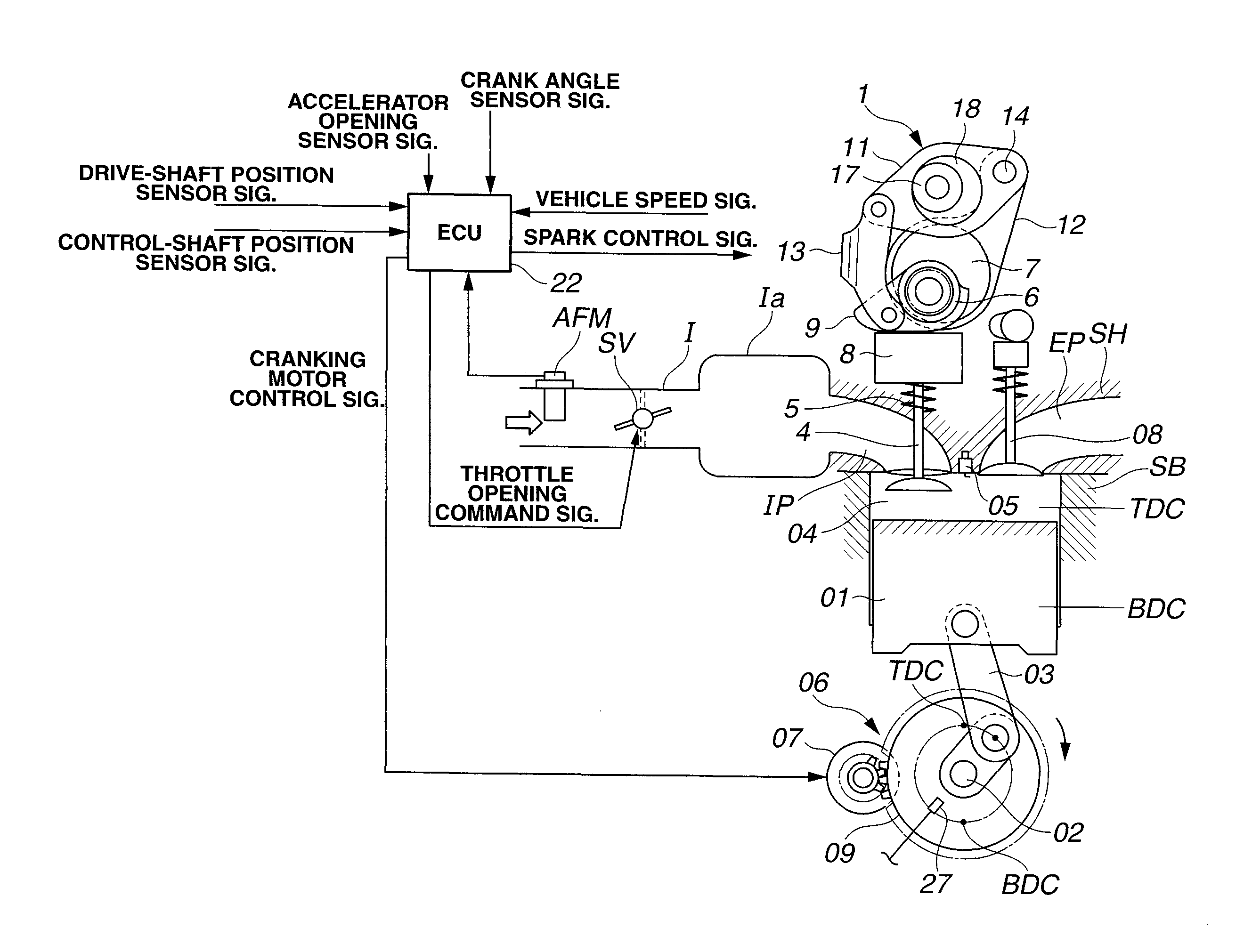

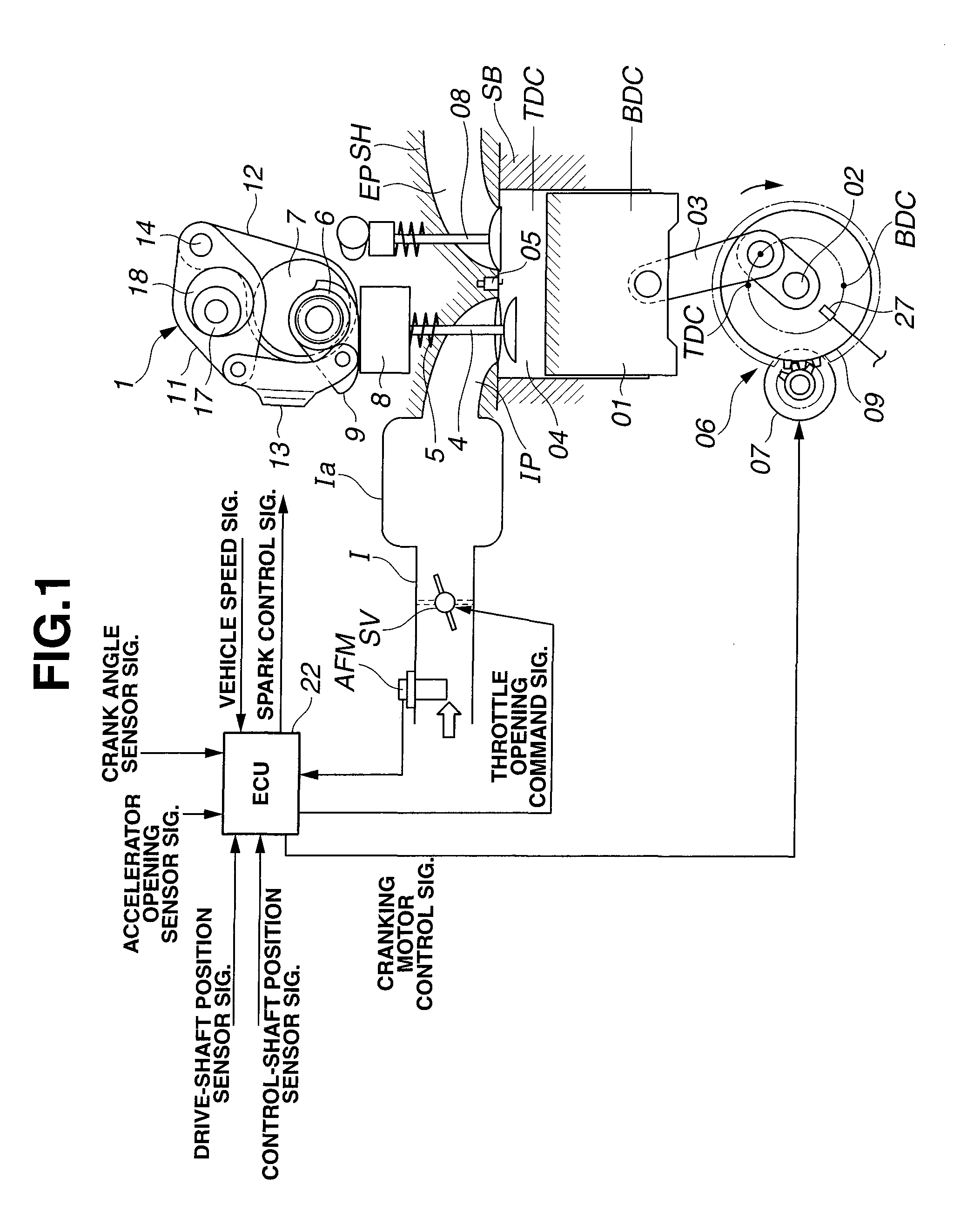

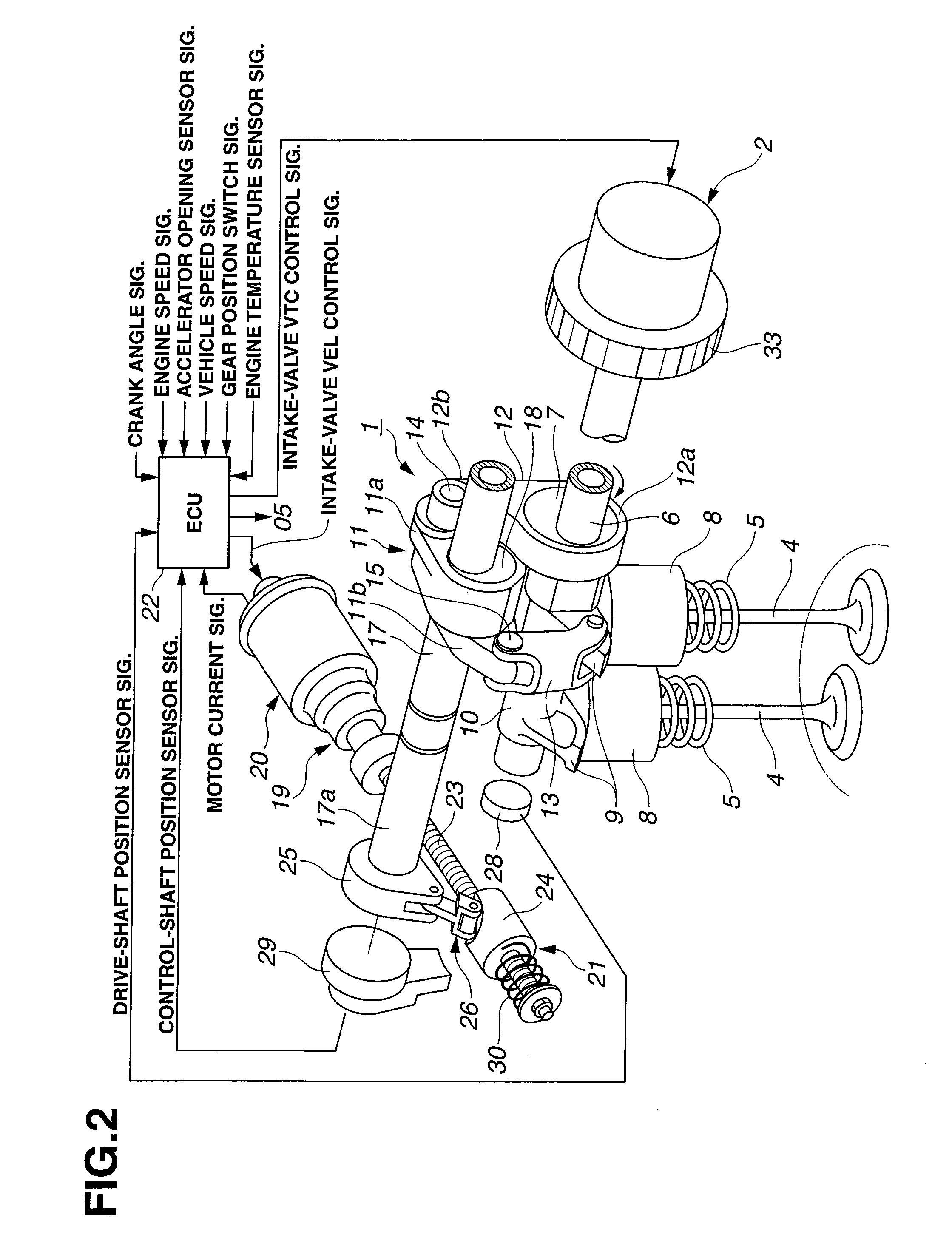

[0022]Referring now to the drawings, particularly to FIGS. 1-2, the engine control device of the first embodiment is exemplified in a four-cycle four-cylinder internal combustion gasoline engine having four valves per cylinder, namely two intake valves 4, 4 (see FIGS. 1-2) and two exhaust valves 08, 08 (see FIG. 1).

[0023]The construction of the multiple-cylinder internal combustion engine, to which the engine control device of the embodiment can be applied, is hereunder described in detail in reference to the system diagram of FIG. 1. Also, the engine control device of the embodiment can be applied to a hybrid vehicle (HV) employing an automatic engine stop-restart system capable of temporarily automatically stopping an internal combustion engine during idling without depending on a driver's will, in addition to an internal-combustion-engine equipped vehicle with a so-called idling-stop system that enables an idling-stop action. The engine of FIG. 1 is constructed by a cylinder bloc...

second embodiment

[0130]Referring now to FIGS. 11A-11B and 12, there is shown the engine control device of the second embodiment wherein the inventive concept is applied to an in-line two-cylinder internal combustion engine. The basic configurations of intake-valve VEL mechanism 1 and intake-valve VTC mechanism 2, both constructing the variable valve actuation device incorporated in the engine control system of the second embodiment, are the same as those of the first embodiment.

[0131]As can be seen from the characteristic diagrams of FIGS. 11A-11B, in the engine stopped state, intake-valve VEL mechanism 1 is held at a default position where the operating mode of each of intake valves 4, 4 is kept at its minimum working angle D1′ operating mode.

[0132]As clearly seen in FIGS. 11A-11B, there is a specific crankangle area α1′, in which intake valves 4, 4 of the two engine cylinders (#1 and #2 cylinders) are kept simultaneously in their closed states, near the TDC position of the #1 cylinder on compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com