Support structure for flat-plate heat pipe

a technology of supporting structure and heat pipe, which is applied in the direction of heat exchangers, indirect heat exchangers, light and heating apparatus, etc., can solve the problems of difficult to provide sufficient working fluid to go back the evaporating end, non-uniform distribution of thermal flux over the surface of heat-generating electronic components, and increasing the problem of heat dissipation, etc., to achieve better thermal uniformity and better heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

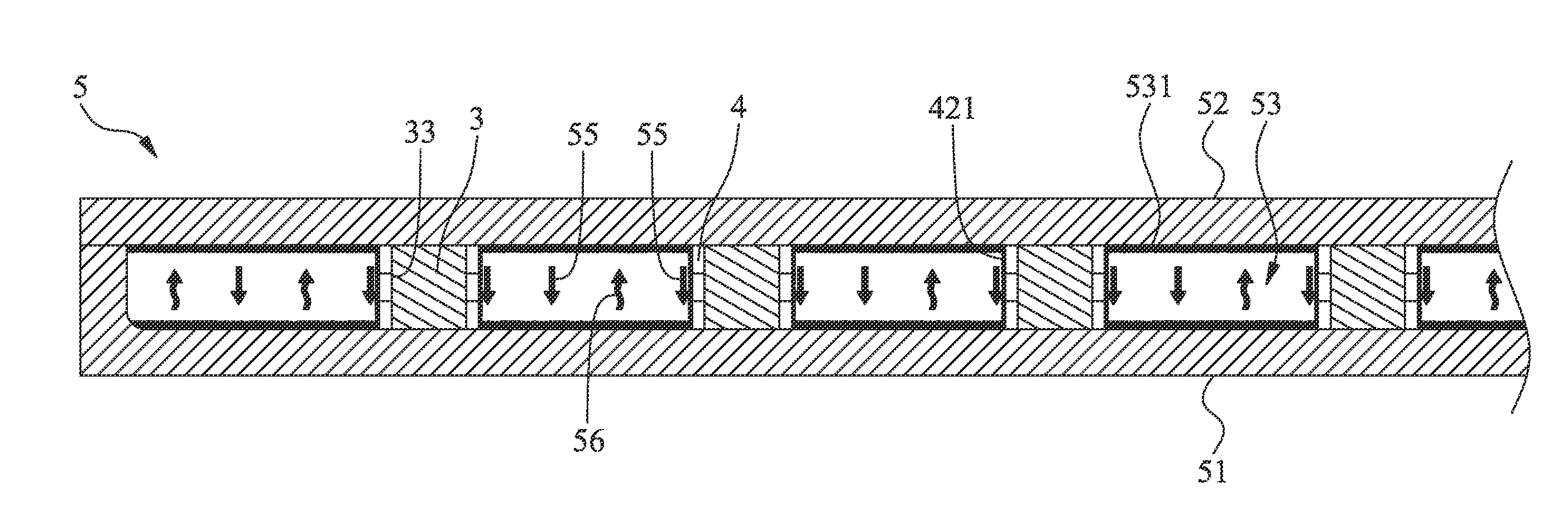

[0022]Please refer to FIGS. 3, 4 and 5. the support structure for flat-plate heat pipe of the present invention includes a main body 3 and a fitting body 4. The fitting body 4 has at least one open side 41 and a first side section 42 connected with the open side 41. The first side section 42 has a capillary structure 421 formed on a periphery of the first side section 42. The capillary structure 421 can be a porous structure in the form of metal spring, metal mesh or sintered metal powder. The capillary structure 421 has flow-guiding ability and provides multiple backflow channels. Accordingly, the capillary structure 421 serves to guide the fluid to quickly flow from the colder portion back to the heated portion so as to enhance fluid circulating rate and increase flow amount and prevent the fluid flowing within the heated portion from drying out. Alternatively, the periphery of the first side section 42 can be directly formed with channel-shaped or porous capillary structure 421 ...

second embodiment

[0030]FIGS. 6 to 8 show the present invention, in which several fitting bodies 4 are stacked and fitted around the main body 3. To speak more specifically, the fitting bodies 4 are sequentially fitted around the main body 3 with the total of the heights of the fitting bodies 4 equal to the height of the main body 3. In this case, the fitting bodies 4 and the main body 3 fitted therein are arranged between the first and second flat plates 51, 52 in abutment therewith. In this embodiment, the number of the fitting bodies 4 is, but not limited to, three. Alternatively, there can be four, five, six or more fitting bodies in accordance with the height of the main body 3. That is, the number of the fitting bodies 4 is determined by the actual height of the main body 3.

[0031]According to the aforesaid, the support structure for flat-plate heat pipe of the present invention has the following advantages:[0032]1. The present invention has better heat dissipation effect.[0033]2. The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com