Fast jack hybrid liftboat hull

a hybrid and liftboat technology, applied in special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of inconvenient construction, high cost of downward-pointing propellers, and difficulty in equipping a standard barge hull with a functional bow thruster, etc., to achieve easy utilization, high capacity, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

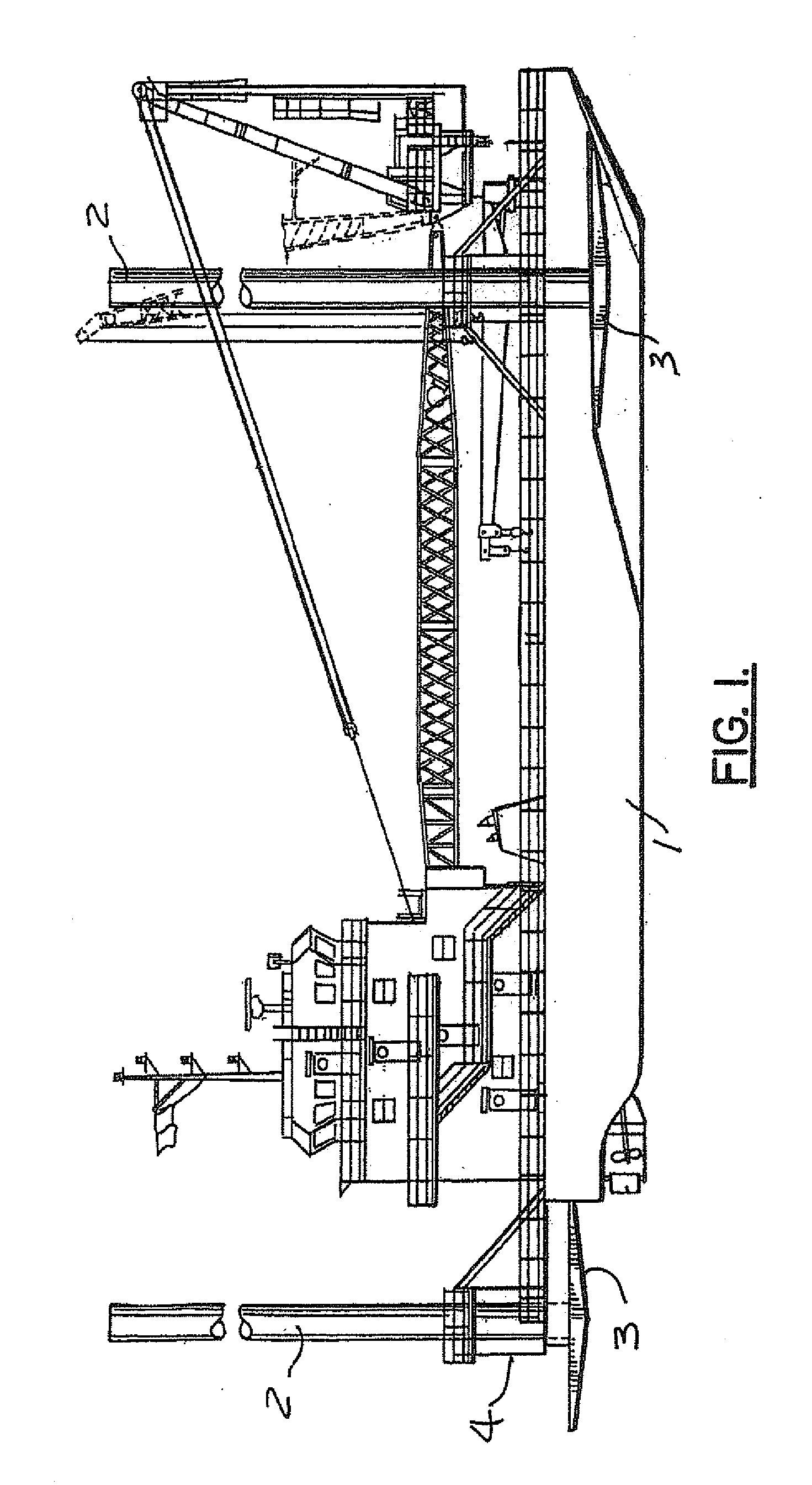

[0023]FIG. 1 depicts an outboard profile of a typical liftboat as currently known in the art. Shown is the hull 1, the legs 2, the pads 3, the jacking towers 4, sponsons 5, while the actual jacking system is not shown.

[0024]Referring to FIG. 1, the disadvantages of current liftboat design and construction are apparent. Construction of sponsons and overhangs is unnecessarily complicated and inherently weaker than an integrated design. Compound curve of stern rake is difficult to construct / repair. Having the keel coolers on inside of hull creates several problems including corrosion of piping and electrical wiring inside wet tanks and voids. Catch water in pockets can cause localized corrosion, creating the need to repair or cut out and replace sections in hard to reach places. This means down time and repair expenses compounded by damage done to the inside of the engine room trying to replace cooler under a generator set or engine. Internal coolers make it hard to clean and rinse the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com