Semiconductor light emitting module and method of manufacturing the same

a technology of semiconductor light emitting modules and light-emitting modules, which is applied in the direction of semiconductor devices for light sources, light and heating apparatus, planar light sources, etc., can solve the problems of preventing the creation of a lightweight semiconductor light-emitting module and the ineffective heat dissipation from the front surface, and achieves a high reflection coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A Structure of a Semiconductor Light Emitting Module

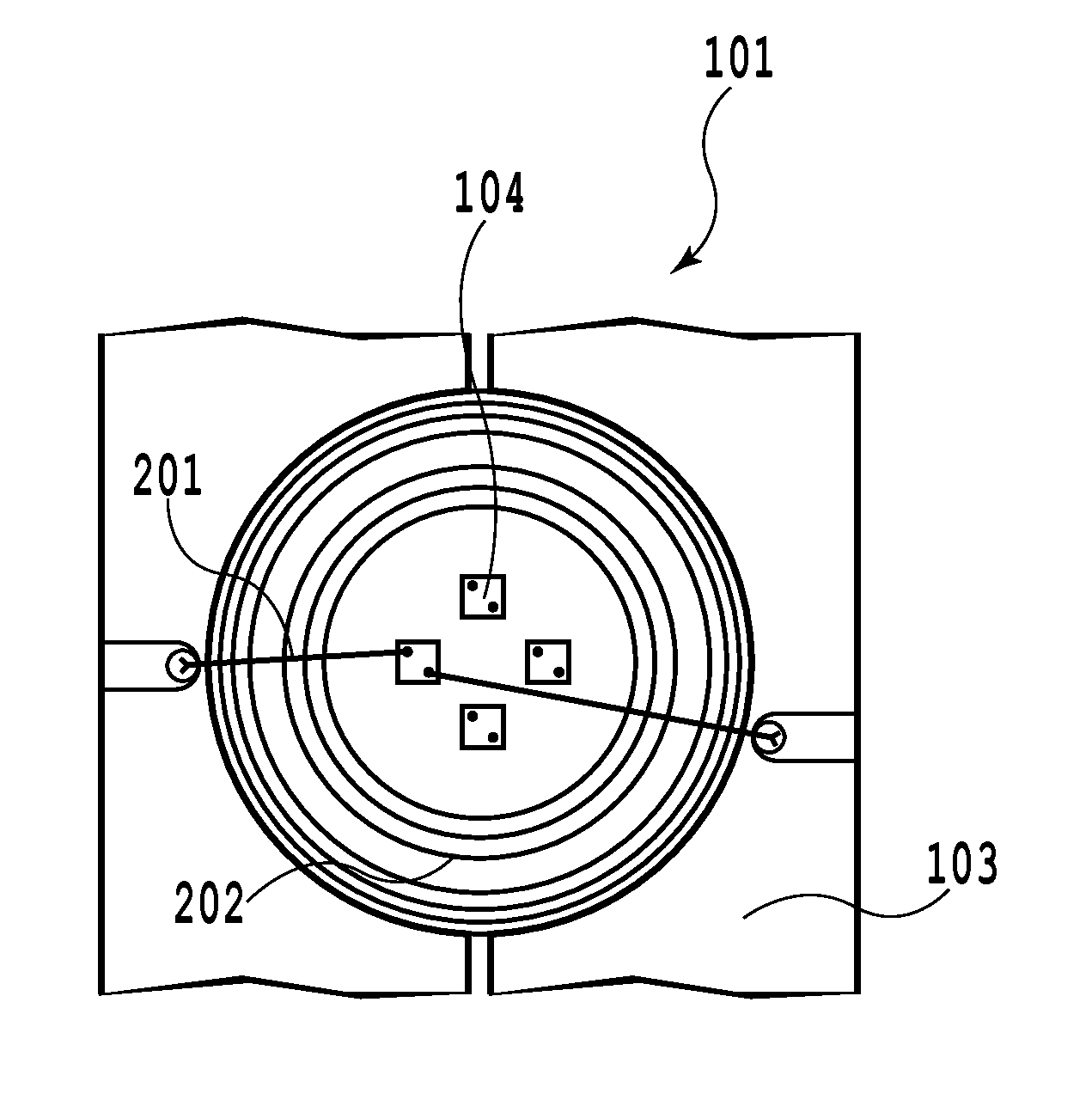

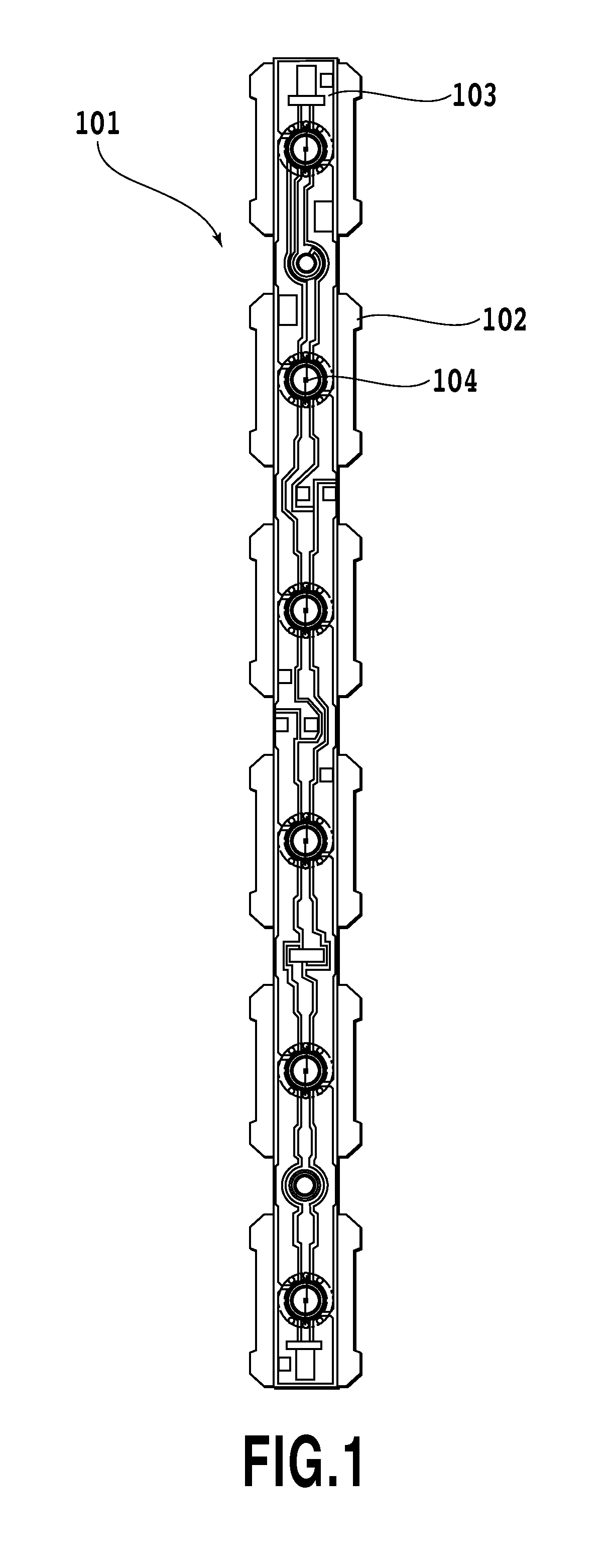

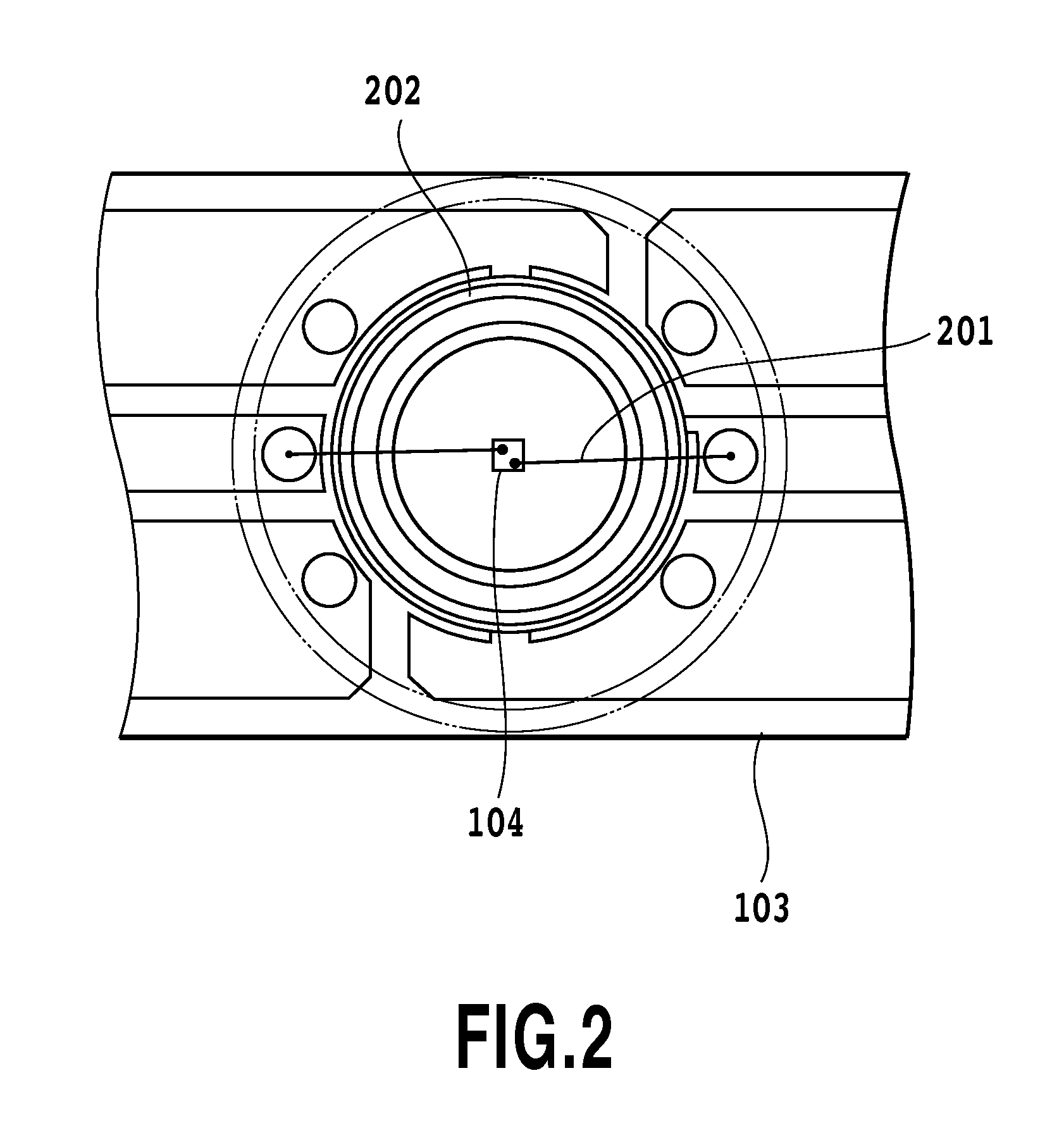

[0058]FIG. 1 is a top view showing a structure of a semiconductor light emitting module according to an embodiment of the present invention. A semiconductor light emitting module 101 of this embodiment includes metal thin plates 102 configured to dissipate heat and provided with a light reflecting function, and a printed board 103 configured to cover the metal thin plates 102 and to supply electric power to semiconductor light emitting elements 104 disposed on the metal thin plates. The semiconductor light emitting elements 104, such as light-emitting diodes, to be actually energized to emit light are electrically connected to the printed board 103. In this embodiment, the printed board 103 is formed into a vertically long shape as shown in FIG. 1, and the metal thin plates 102 are attached thereto in an array form. Here, as can be understood by referring to FIG. 1, the metal thin plates 102 are structurally formed into such shapes...

second embodiment

[0084]FIGS. 14A and 14B are a front view and a lateral side view showing a structure of an example of a semiconductor light emitting module according to this embodiment. As similar to the above-described first embodiment, a semiconductor module of this embodiment similarly forms therein the projecting portion 202 serving as the reflecting member on the metal thin plate 102 in a way that the projecting portion 202 surrounds the semiconductor light emitting element 104, and connects the semiconductor light emitting element 104 to the printed board 103 by using the wire 201 or the like, for example, but is different in that a high reflection paint portion 1401 is provided at a gap portion between the printed board covering the metal thin plate 102 and the projecting portion 202 as shown in FIG. 14B.

[0085]Specifically, the printed board 103 having an opening for the projecting portion 202 is formed so as to be stacked on the metal thin plate 102 in the first embodiment. Here, as can be ...

third embodiment

[0090]FIGS. 15A and 15B are a front view and a lateral side view showing a structure of an example of a semiconductor light emitting module according to this embodiment. The semiconductor module of this embodiment is similar to the above-described second embodiment in that the a high reflection paint portion 1501 is provided at an edge portion of an opening of the printed board 103 to cover the metal thin plate 102 and is different from the second embodiment in that the metal thin plate 102 does not include the projecting portion 202 serving as the reflecting member provided so as to surround the semiconductor light emitting element 104.

[0091]Specifically, in the second embodiment, the printed board 103 having an opening for the projecting portion 202 is formed to be stacked on the metal thin plate 102 and the inclined surface of the projecting portion 202 plays a role as a reflecting plate to increase reflection efficiency. Meanwhile, as can be understood by referring to the latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com