Method of Layering Composite Sheets to Improve Armor Capabilities

a composite sheet and armor technology, applied in the field of armor systems, can solve the problems of mine resistant ambush protection vehicles and other armored vehicles that cannot defend against these threats, armor solutions typically weighing around 200 lb/ft, and other problems, to achieve the effect of reducing the amount of force, increasing the impact time, and prolonging the dwell tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]It should be understood at the outset that, although example implementations of embodiments of the invention are illustrated below, the present invention may be implemented using any number of techniques, whether currently known or not. The present invention should in no way be limited to the example implementations, drawings, and techniques illustrated below. Additionally, the drawings are not necessarily drawn to scale. In some embodiments, like numbers in the drawings may refer to like parts.

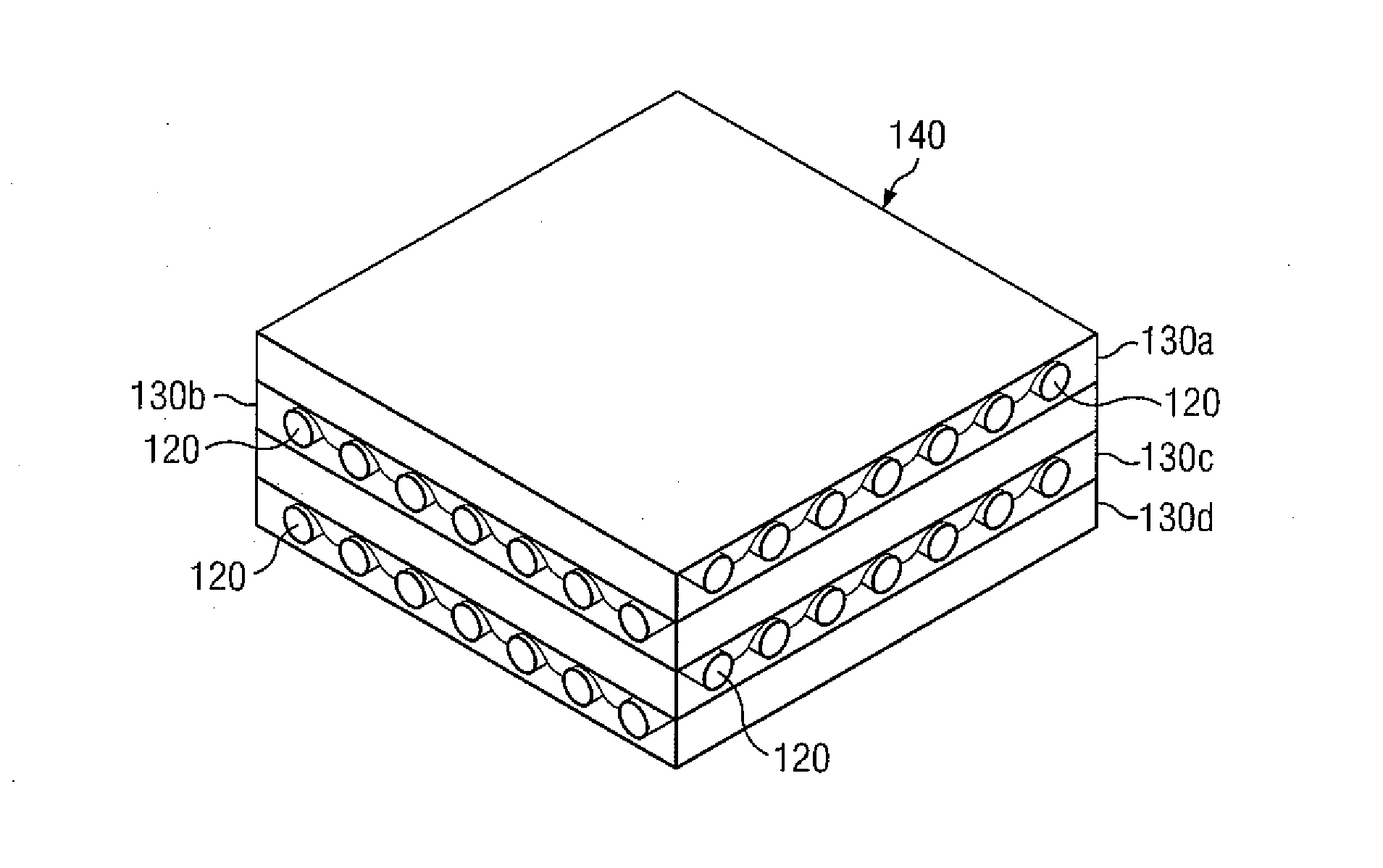

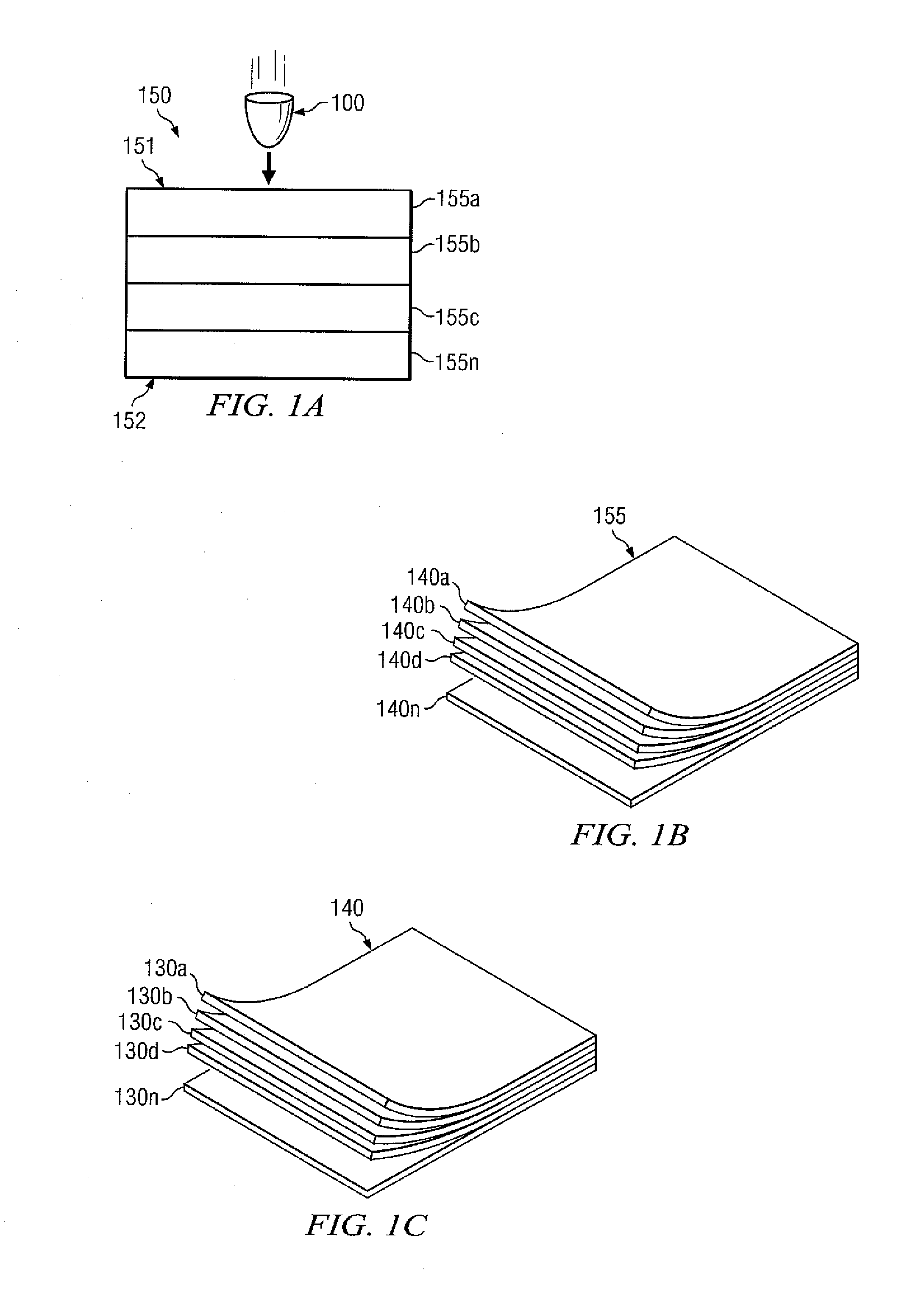

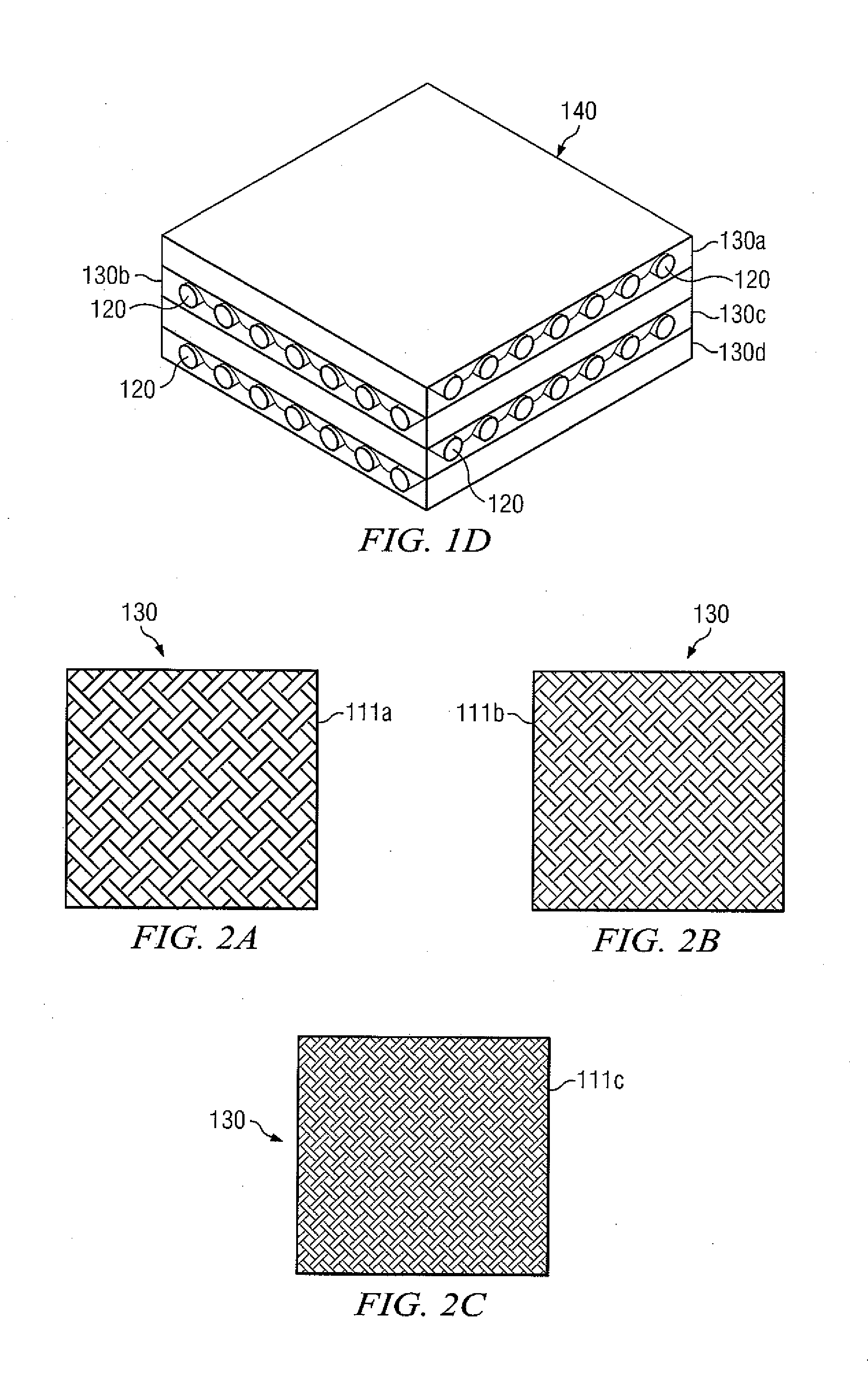

[0044]Teachings of certain embodiments recognize that armor systems may be used to provide protection against and / or reduce impact of various projectiles such as but not limited to shaped charges, EFP's, IEDs, ballistic devices, other explosives and hypervelocity impacts. Armor systems of the disclosure may be used in conjunction with any vehicle, such as but not limited to, military vehicles, convoy vehicles and / or personnel carriers and may be useful to protect personnel and equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com