Support structure for a back part and/or a seat of a seat assembly and seat assembly comprising such a support structure

a support structure and back part technology, which is applied in the direction of vehicle seats, seating furniture, transportation and packaging, etc., can solve the problems of reducing the minimum reset torque, and reducing the reset torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

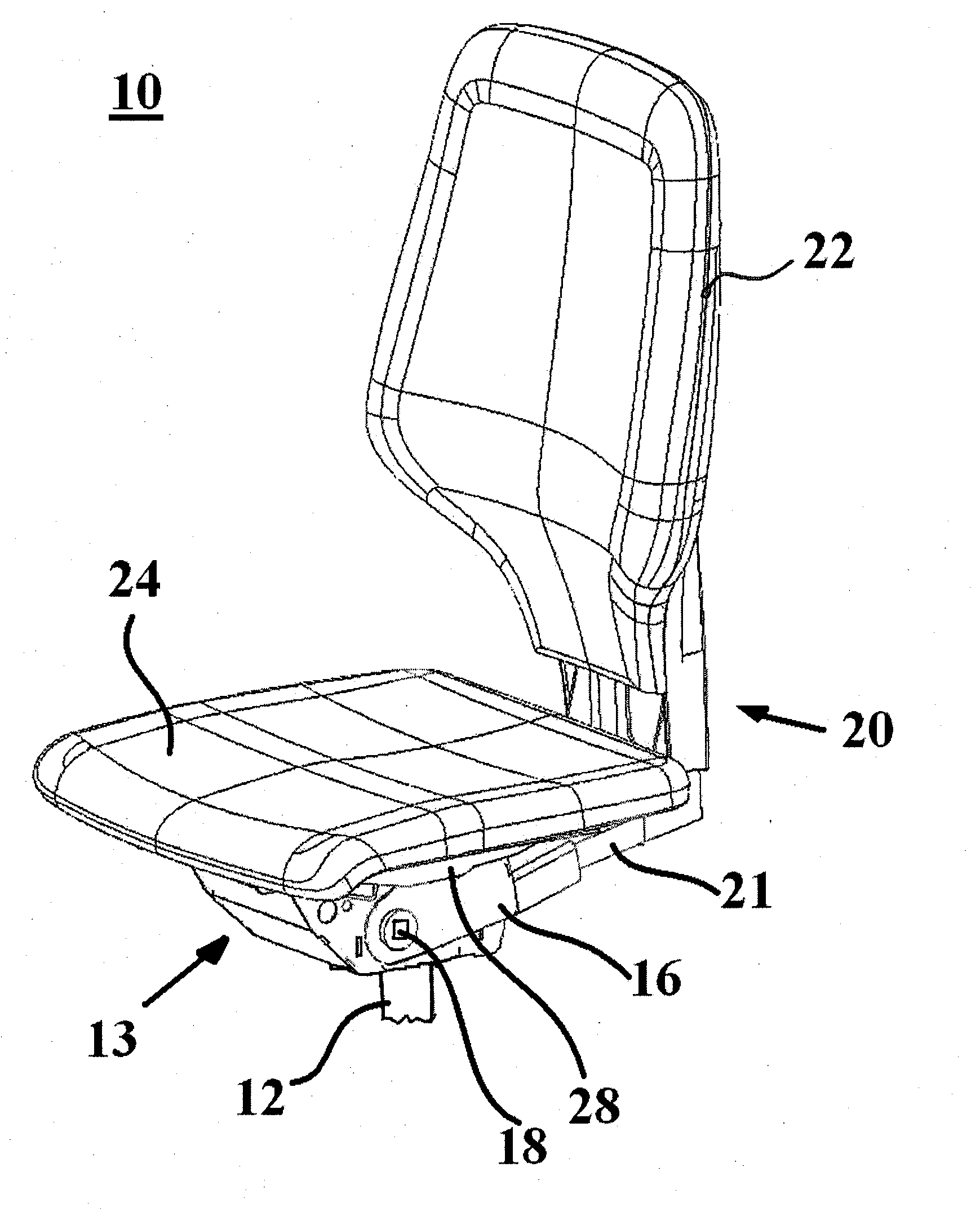

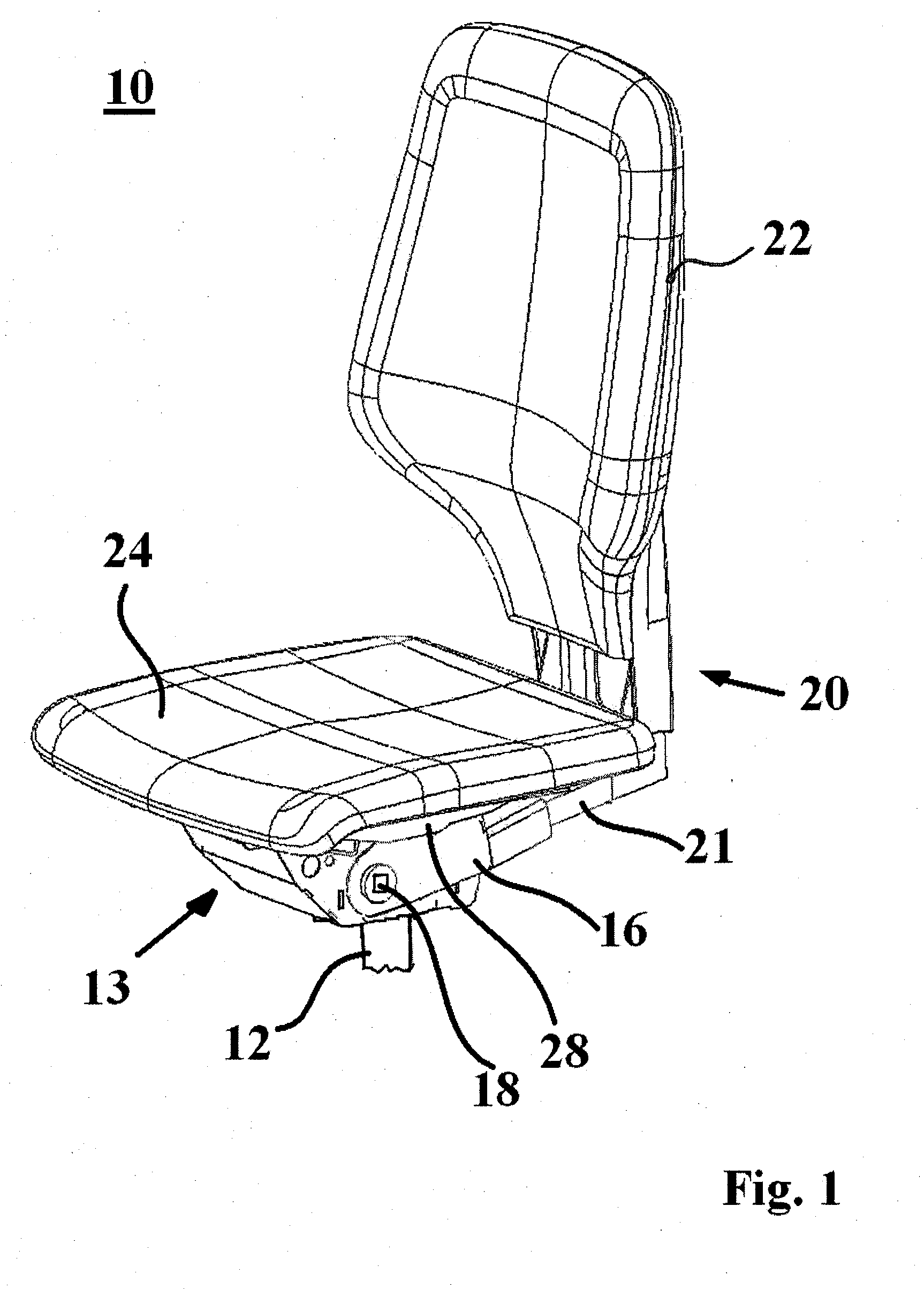

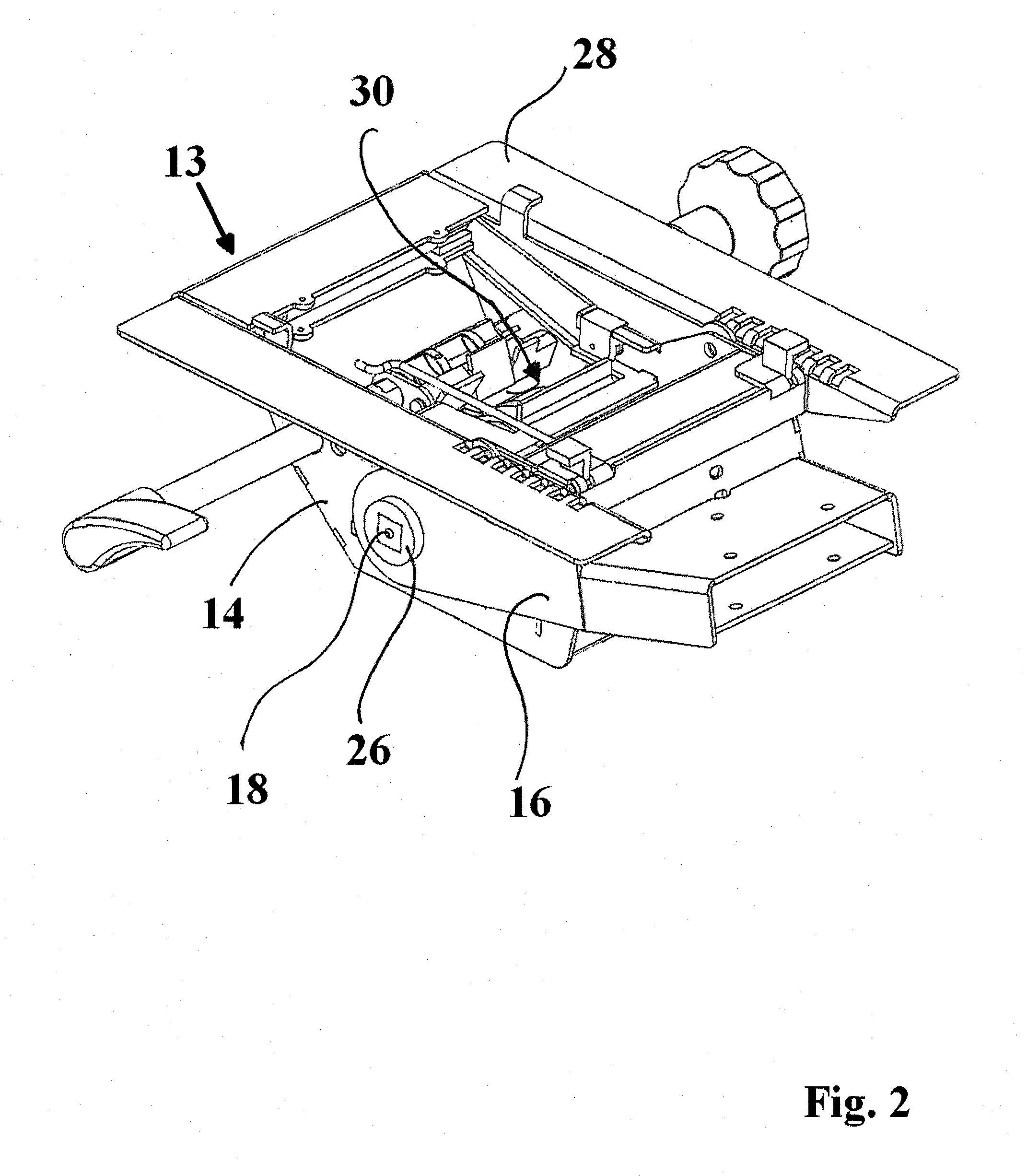

[0063]FIG. 1 shows an exemplary embodiment of a seat assembly in the form of a chair 10. The chair 10 is embodied as an office swivel chair. It comprises a support column 12, a back part 20, a seat 24 and a support structure 13 according to an embodiment of the invention for the back part 20 and for the seat 24. The support structure 13 holds the back part 20 and the seat 24 in a basic position in each case, provided that no load acts on the back part 20 or on the seat 24, respectively, and makes it possible for the back part 20 or the seat 24, respectively, to be able to be deflected out of the respective basic position, provided that a load acts on the back part or on the seat 24, respectively. In the illustration according to FIG. 1, the back part 20 or the seat 24, respectively, are unloaded and are thus in the respective basic position. In this basic position, the back part 22 is oriented in a substantially vertical manner and the seat 24 is oriented in a substantially horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com