Magnesium Fastener Manufacturing Method and A Magnesium Fastener Member Produced Thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]It is noted that a magnesium fastener manufacturing method in accordance with the preferred embodiment of the present invention is suitable for producing various fasteners, for example, including rivets, pins, studs, double-headed studs, washers and other special fasteners which are not limitative of the present invention.

[0038]A magnesium fastener member produced by the magnesium fastener manufacturing method in accordance with the preferred embodiment of the present invention is made from magnesium or magnesium alloys which have a perfect degree of physical and chemical characteristics of magnesium metal. It will be understood that the magnesium fastener member may not be made from other ordinary metals, including stainless steel, low-carbon steel (mild steel), medium carbon steel, alloy steel and bronze, for example.

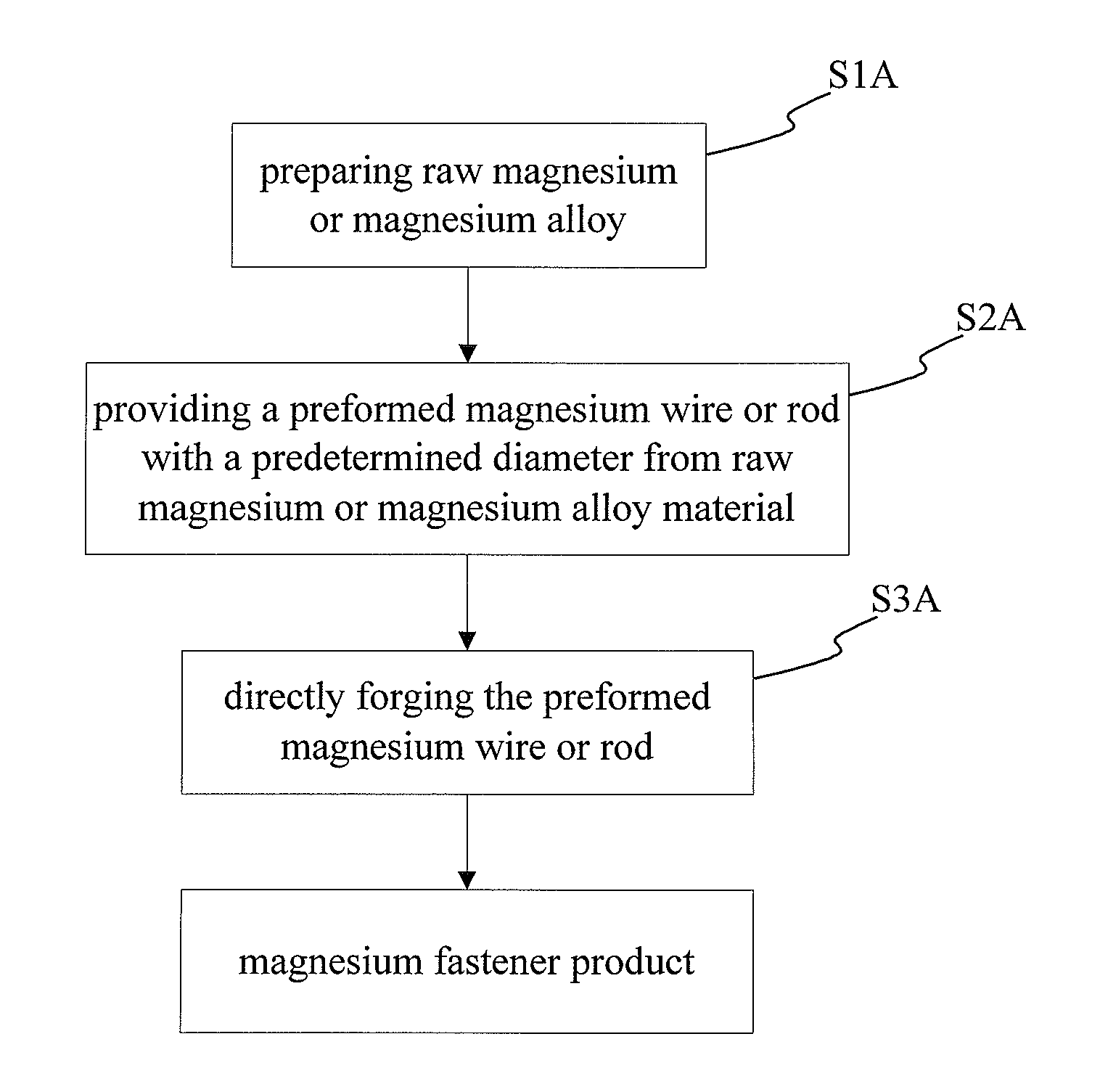

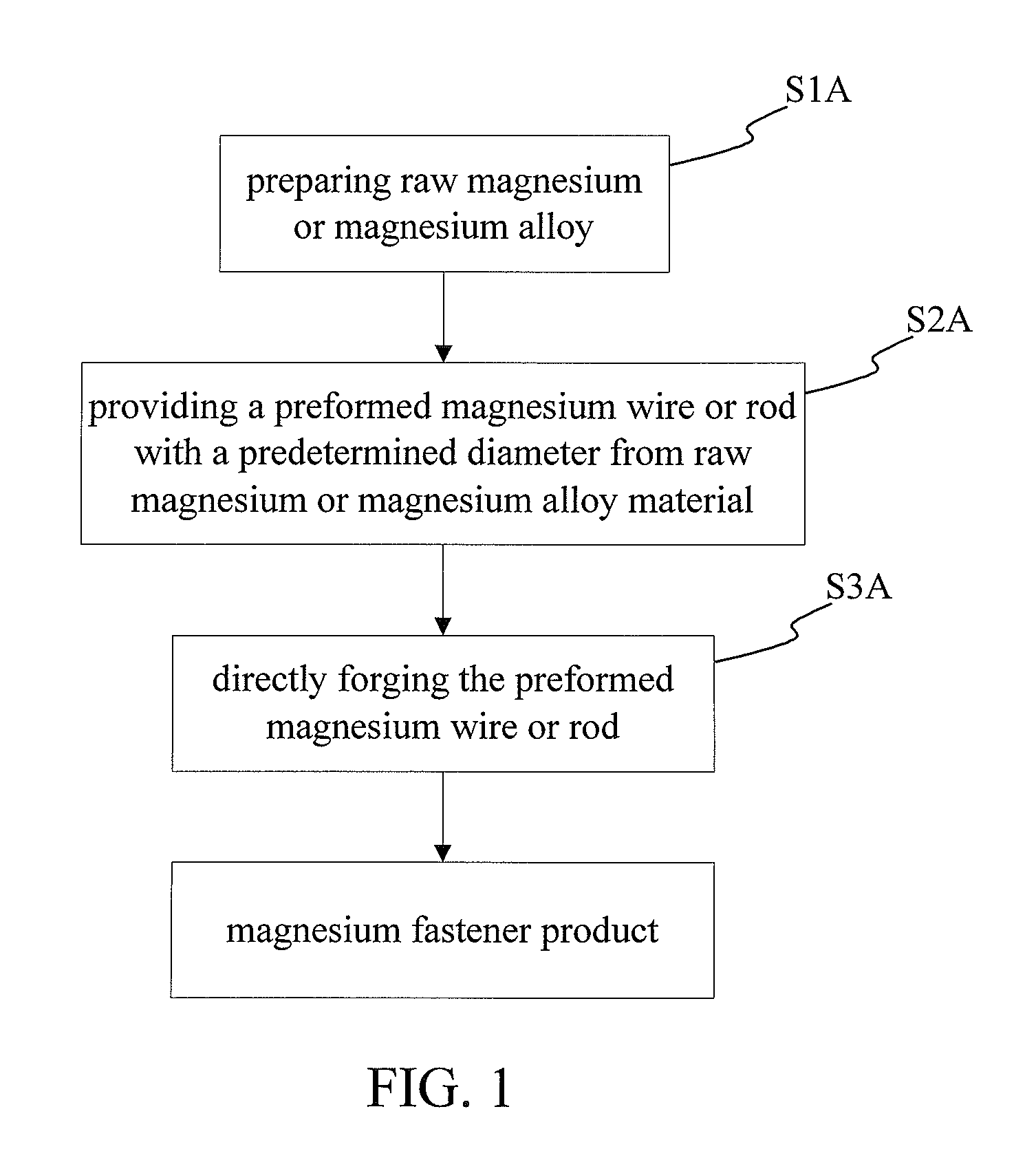

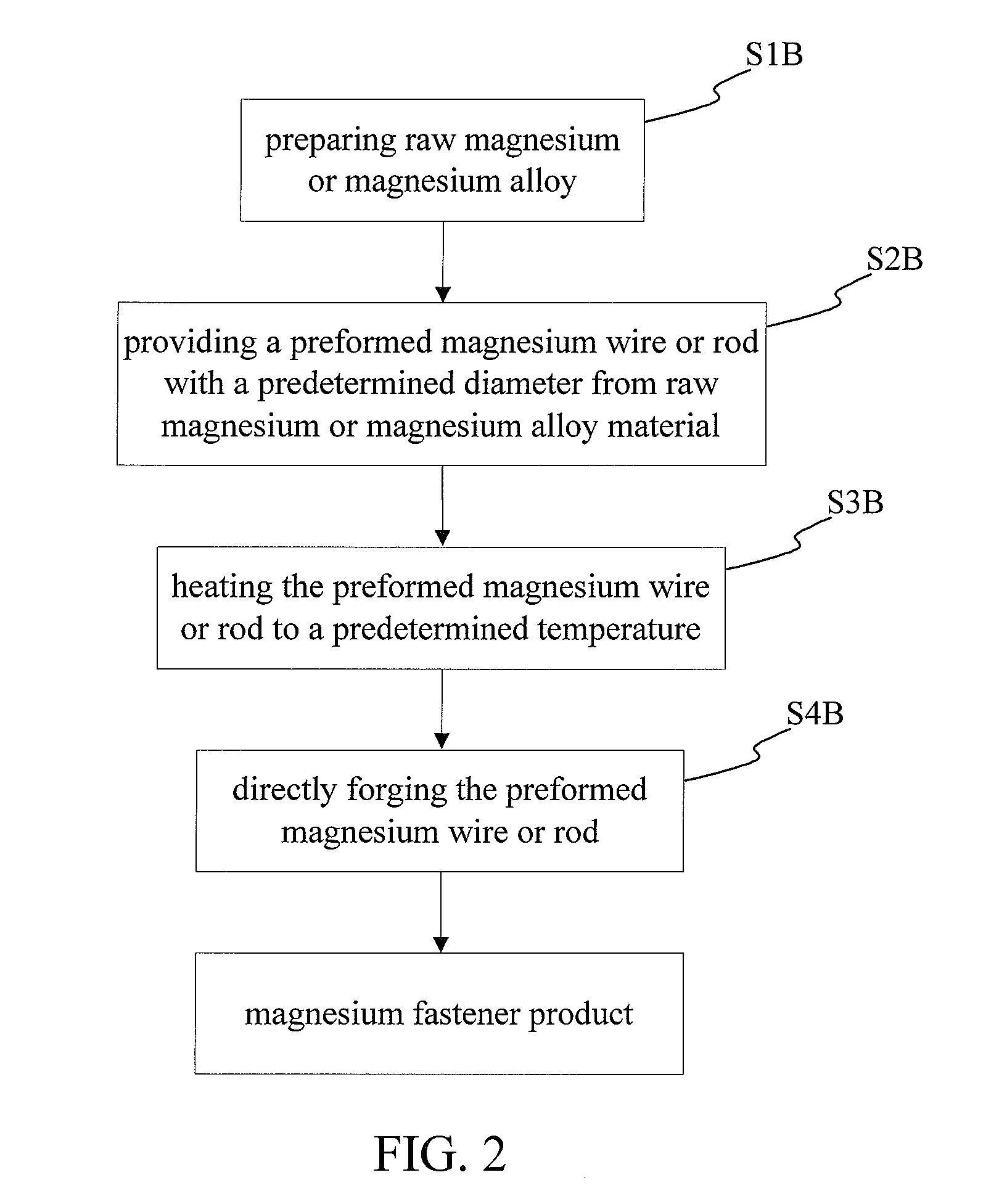

[0039]FIG. 1 shows a flow chart of a magnesium fastener manufacturing method in accordance with a first preferred embodiment of the present invention. With cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com