Roof clamp for fall protection safety equipment

a safety equipment and roof technology, applied in the field of roof safety equipment, can solve the problems of limiting work area, wasting time and effort, and not allowing easy movement over the roo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

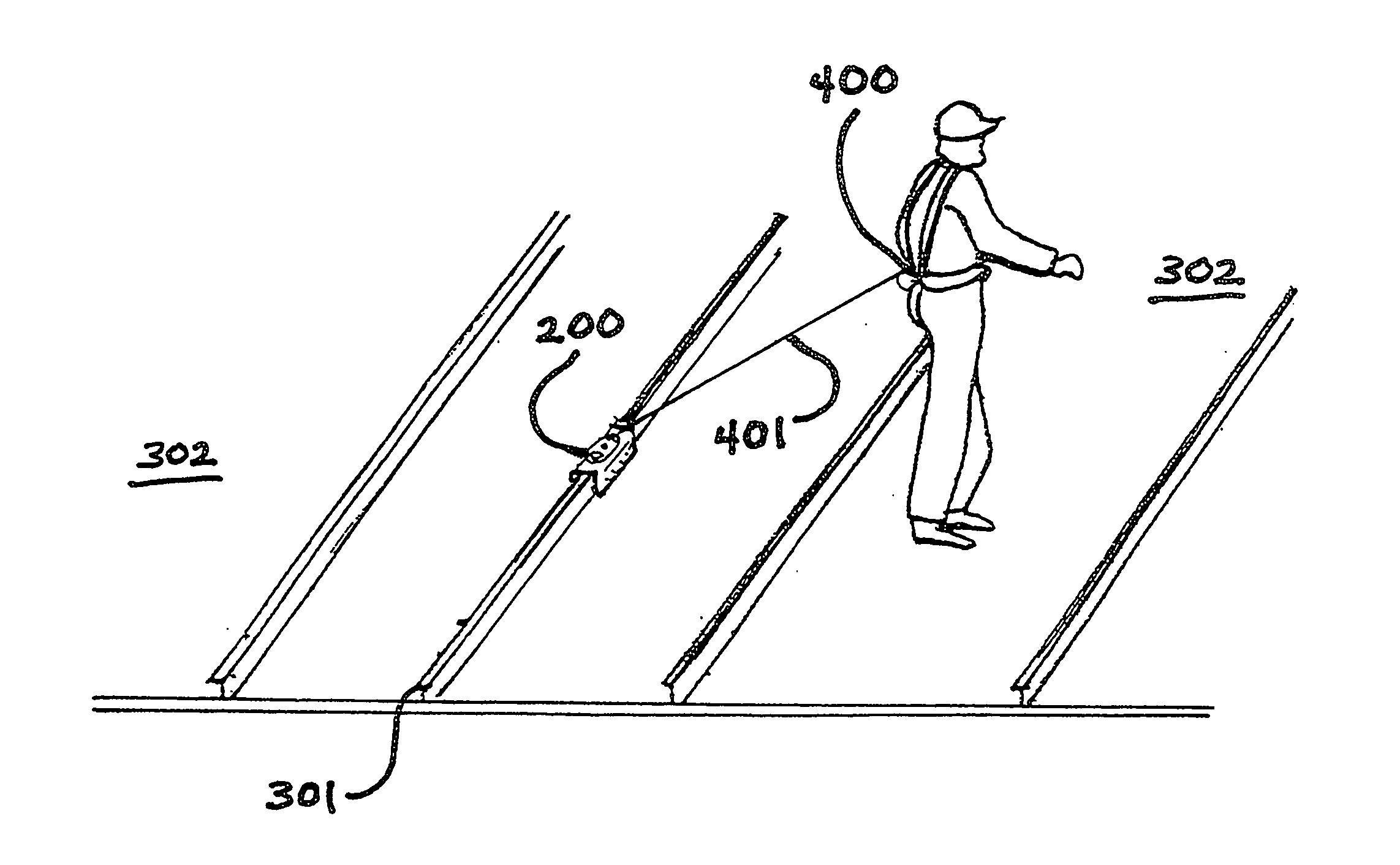

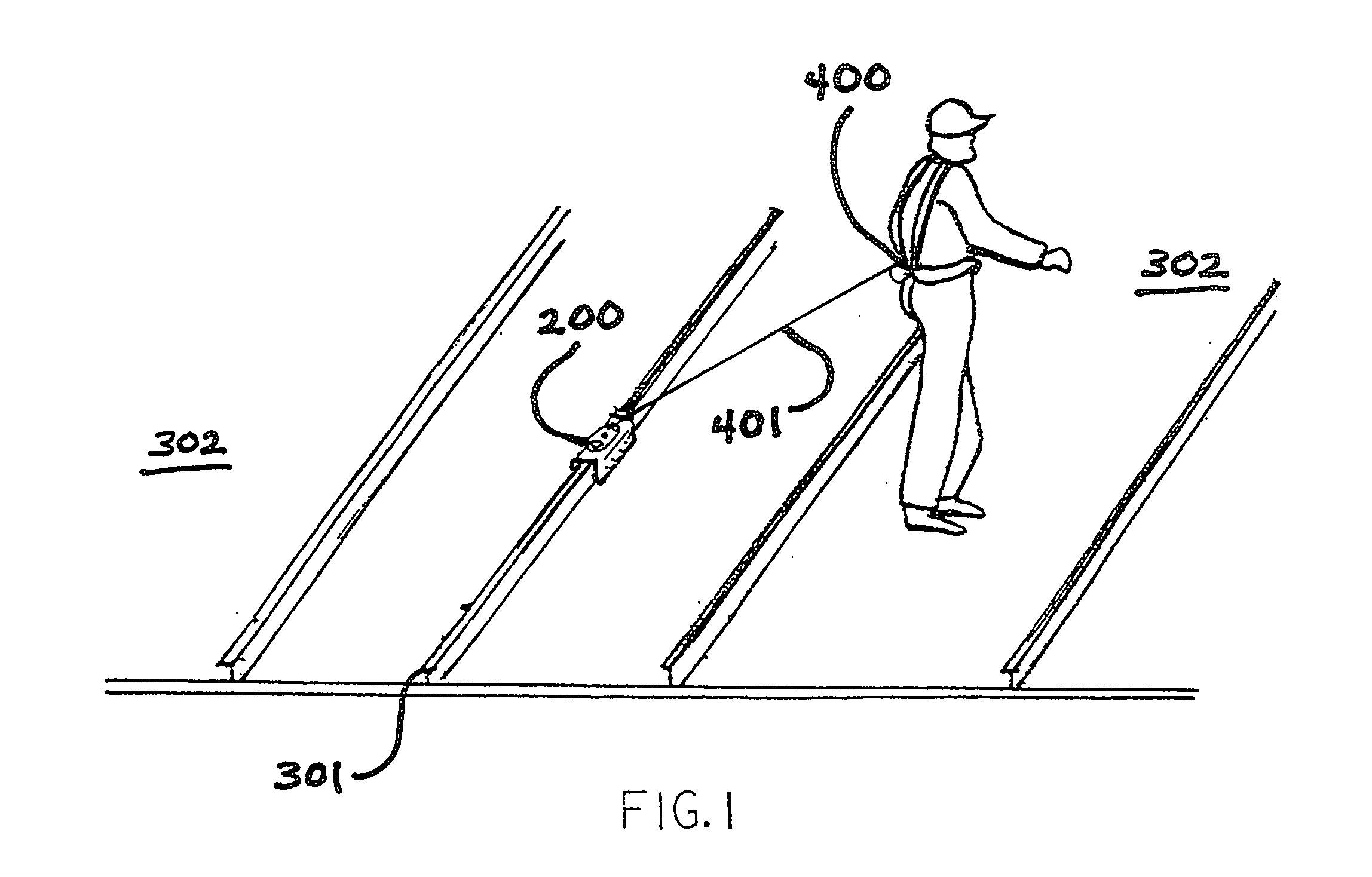

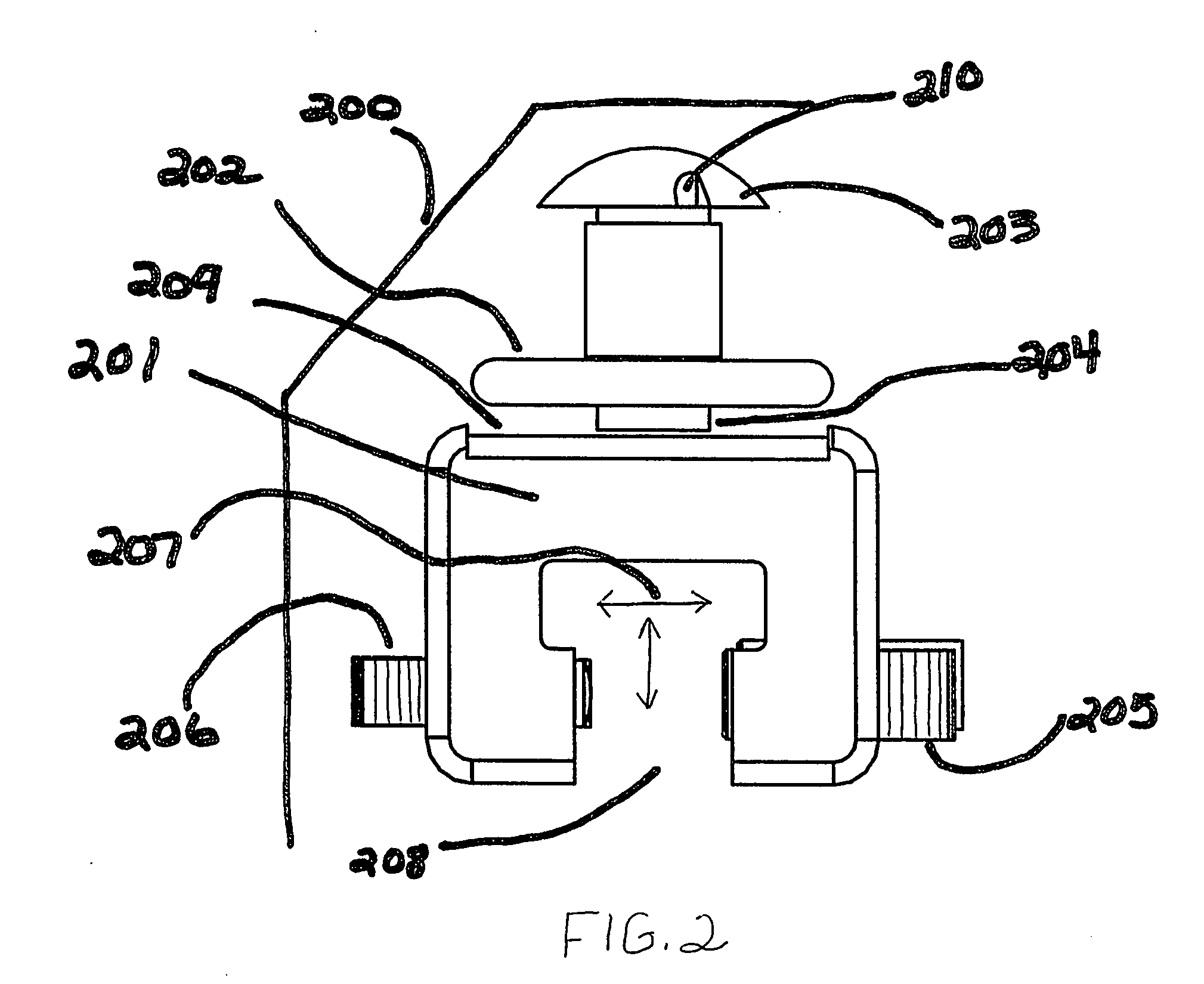

Referencing to FIG. 1, there is shown a fall protection clamp assembly 200 according to the present invention for securing a safety fall protection line 401 to a seam roof 302 and the raised seam 301 present in this roof construction method. The safety fall protection system line 401 coming from the fall protection clamp assembly 200, in turn, is secured to an approved fall protection device 400 such as an approved safety belt, harness or the like as worn by roof workers. The seam roof 302 is made up of formed panels connected together in such a way to secure them to a building and also prevent outside weather elements from entering. These connections, or seams, run the length of the roof and are spaced along its width. The clamp assembly 200 is comprised of a single piece main body 201 made with a unique profile as illustrated in FIG. 2 and may be formed by machine milling or extrusion and is made of aluminum. The profile slot is longitudinal and has an opening 208 along its bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com