Variable valve timing apparatus for internal combustion engine

a technology of variable valve timing and internal combustion engine, which is applied in the direction of valve arrangement, mechanical equipment, machines/engines, etc., can solve the problem of low amount and achieve the effect of suppressing any adverse effect of variable valve timing performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example embodiment

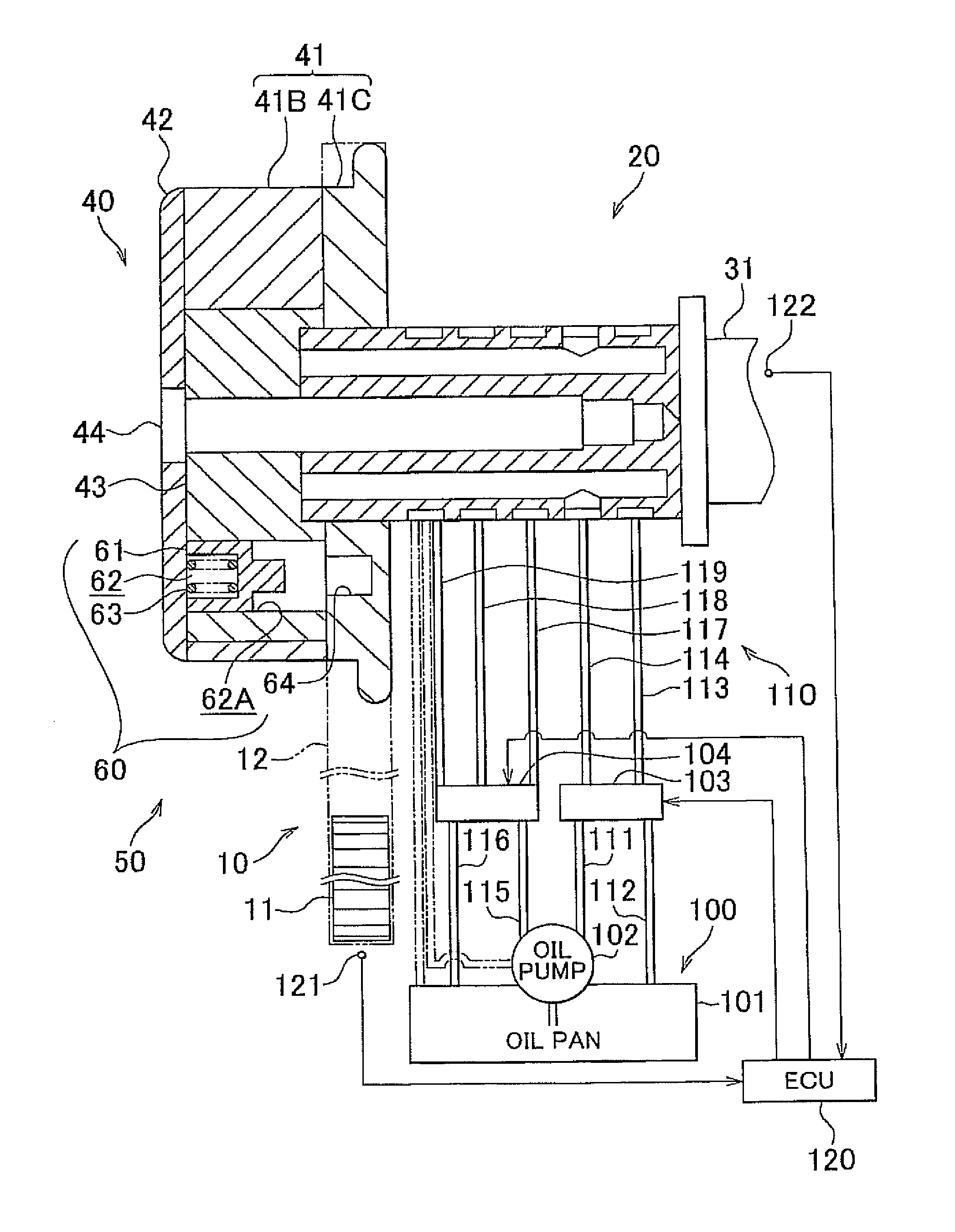

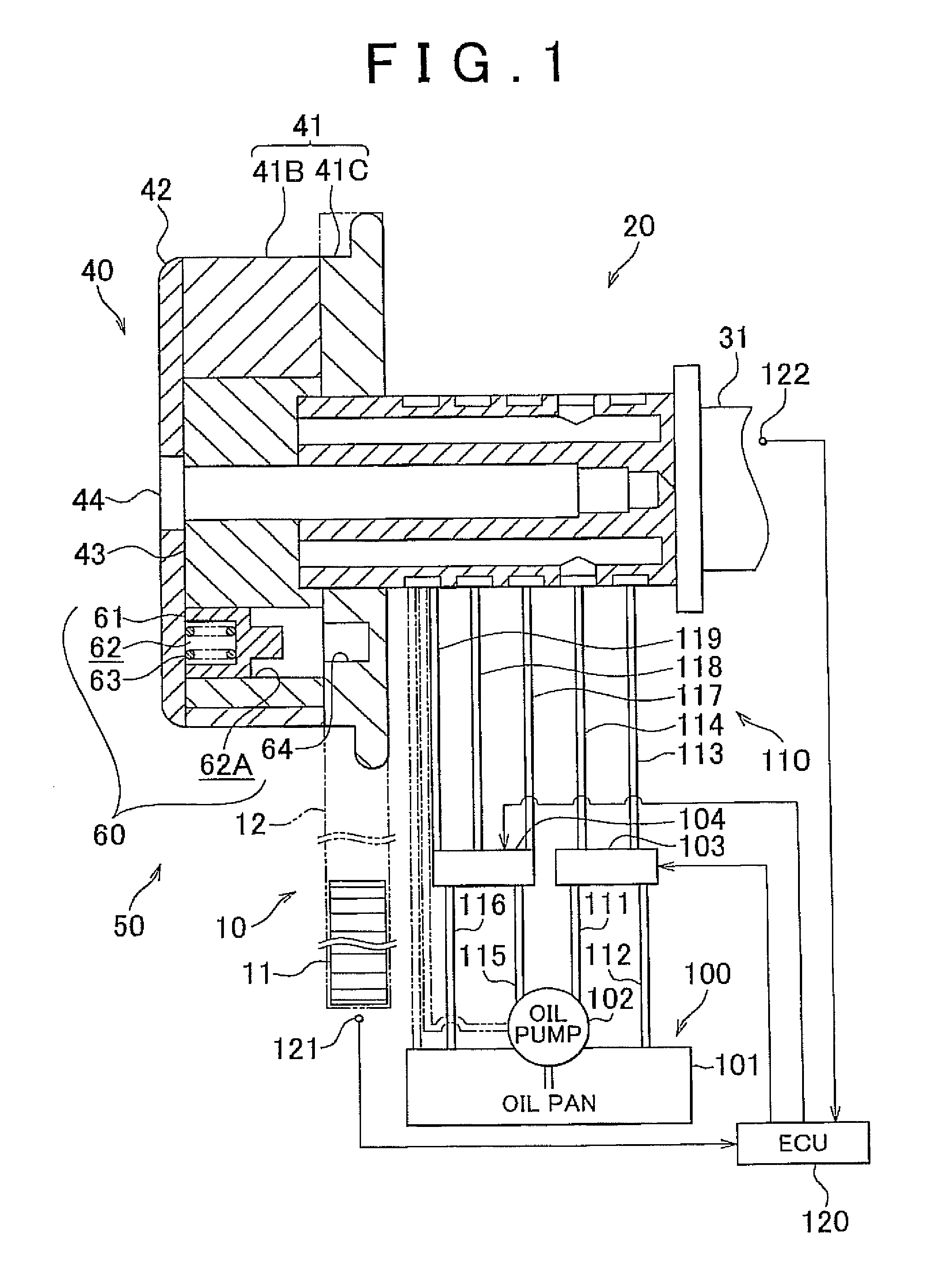

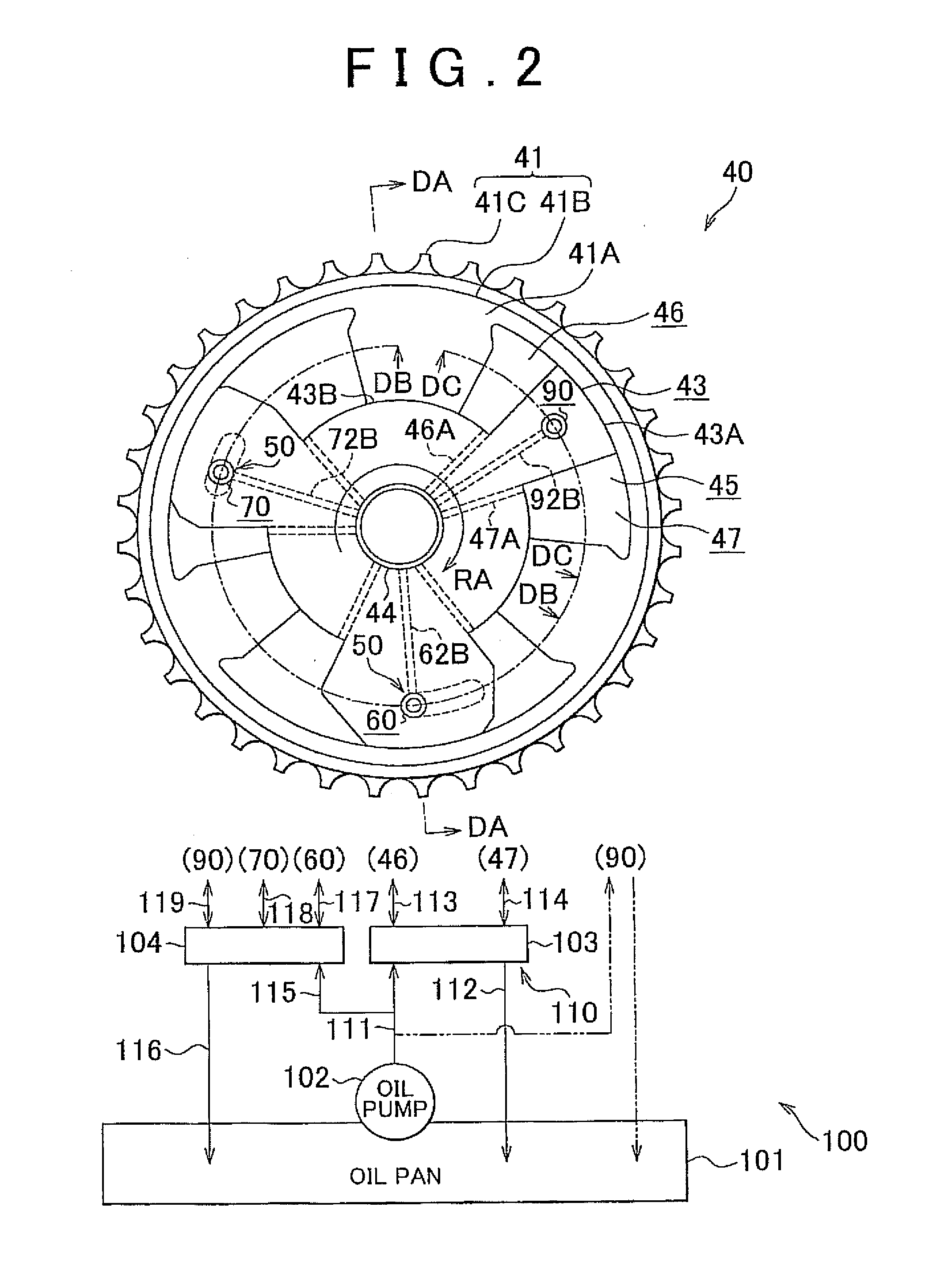

[0033]A first example embodiment of the variable valve timing apparatus for an internal combustion engine of the invention, in which this variable valve timing apparatus is one that changes the valve timing of an intake valve, will be described with reference to FIGS. 1 to 6. Incidentally, in the description below, the term “valve timing” refers to the valve timing of the intake valve unless otherwise specified.

[0034]As shown in FIG. 1, an oil pan 101 in which hydraulic fluid for driving various hydraulically driven auxiliary devices is stored is mounted to a lower portion of an internal combustion engine 10. Meanwhile, a camshaft 31 for driving an intake valve, not shown, open and closed is provided in an upper portion of the internal combustion engine 10, and a variable valve timing apparatus 20 for changing the valve timing is provided on this camshaft 31. The rotational force of a crankshaft 11 is transmitted from a chain 12 to the camshaft 31 of the intake valve via the variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com