Heat exchanger having an inlet distributor and outlet collector

a technology of inlet distributor and collector, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of poor refrigerant distribution throughout the refrigerant tube, uneven temperature distribution over the core, and the length of the inlet and outlet headers, so as to achieve less sensitive to criteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further described with reference to the accompanying drawings, wherein like numerals indicate corresponding parts throughout the views.

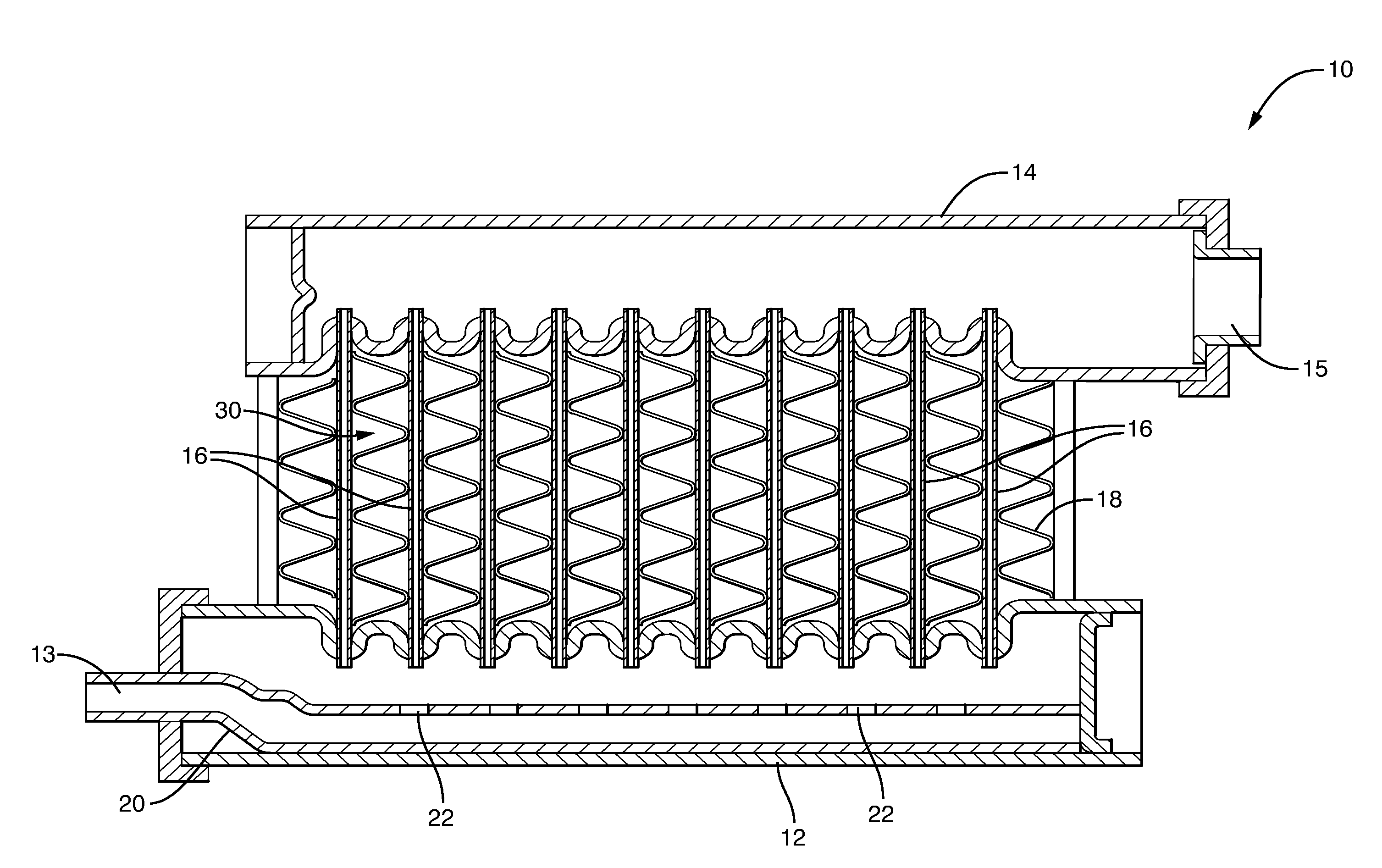

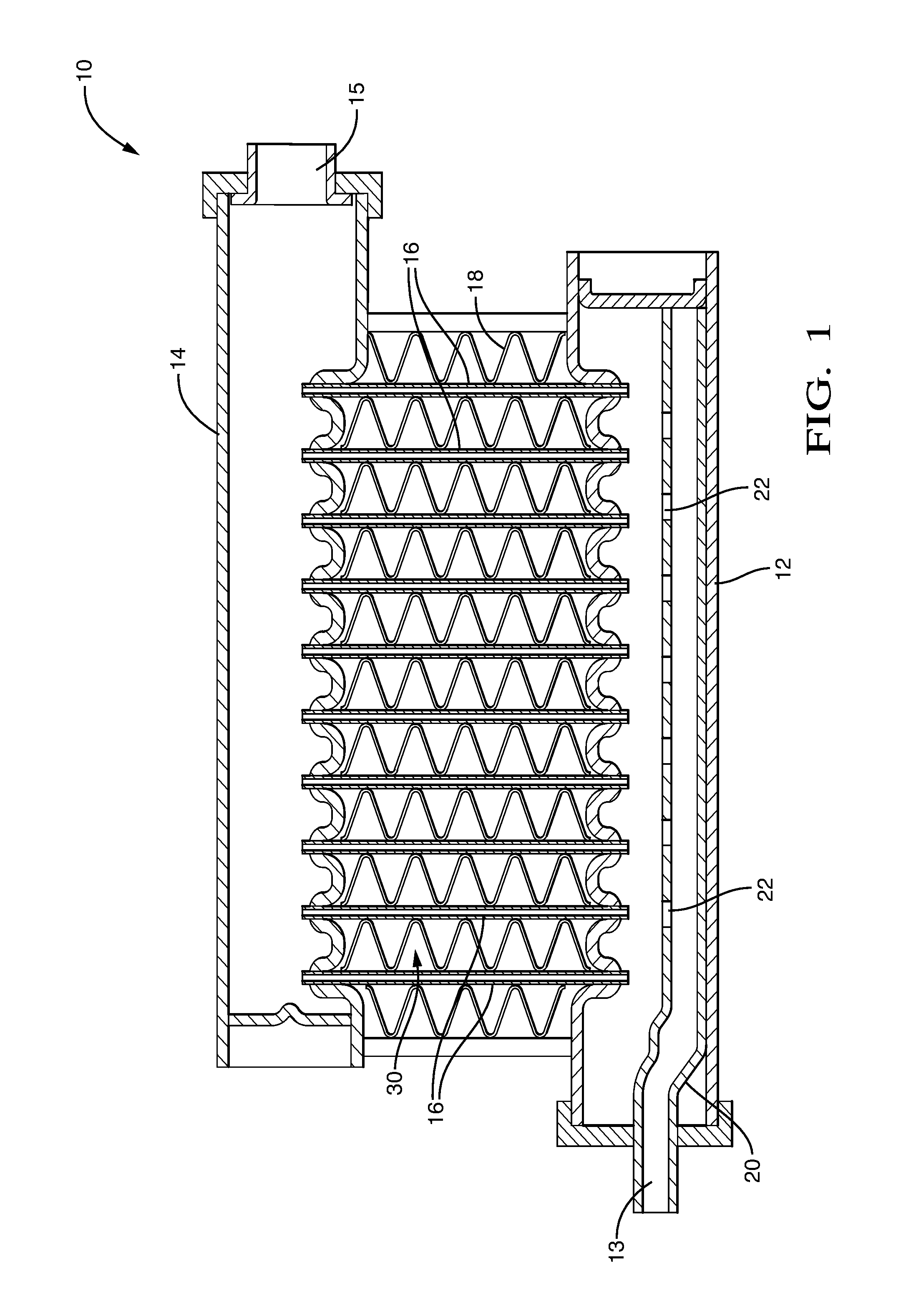

[0021]Shown in FIG. 1 is a prior art modified automotive style heat exchanger assembly 10 modified for stationary use in a residential or commercial setting. The heat exchanger assembly 10 includes an inlet header 12 in hydraulic communication with an outlet header 14 via a plurality of extruded multi-port refrigerant tubes16. Interconnecting the refrigerant tubes 16 are corrugated fins 18 for enhanced heat transfer and increased structural integrity of the heat exchanger assembly 10. The plurality of refrigerant tubes 16 together with the fins 18 defines the core 30 of the heat exchanger assembly 10. Disposed within the inlet header 12 is a distributor tube 20 to assist in the even distribution of refrigerant within the inlet header 12 with the objective of evenly distributing the refrigerant through the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com