Shoe Having A Midsole With Heel Support

a technology of midsole and heel support, which is applied in the field of athletic footwear, can solve the problems of inability to reduce the labor required to manufacture a shoe by a meaningful amount, large number of components, and large number of components, and achieve the effect of reducing the specialized individual labor required, eliminating or reducing the heel counter, and facilitating the attachment of the upper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

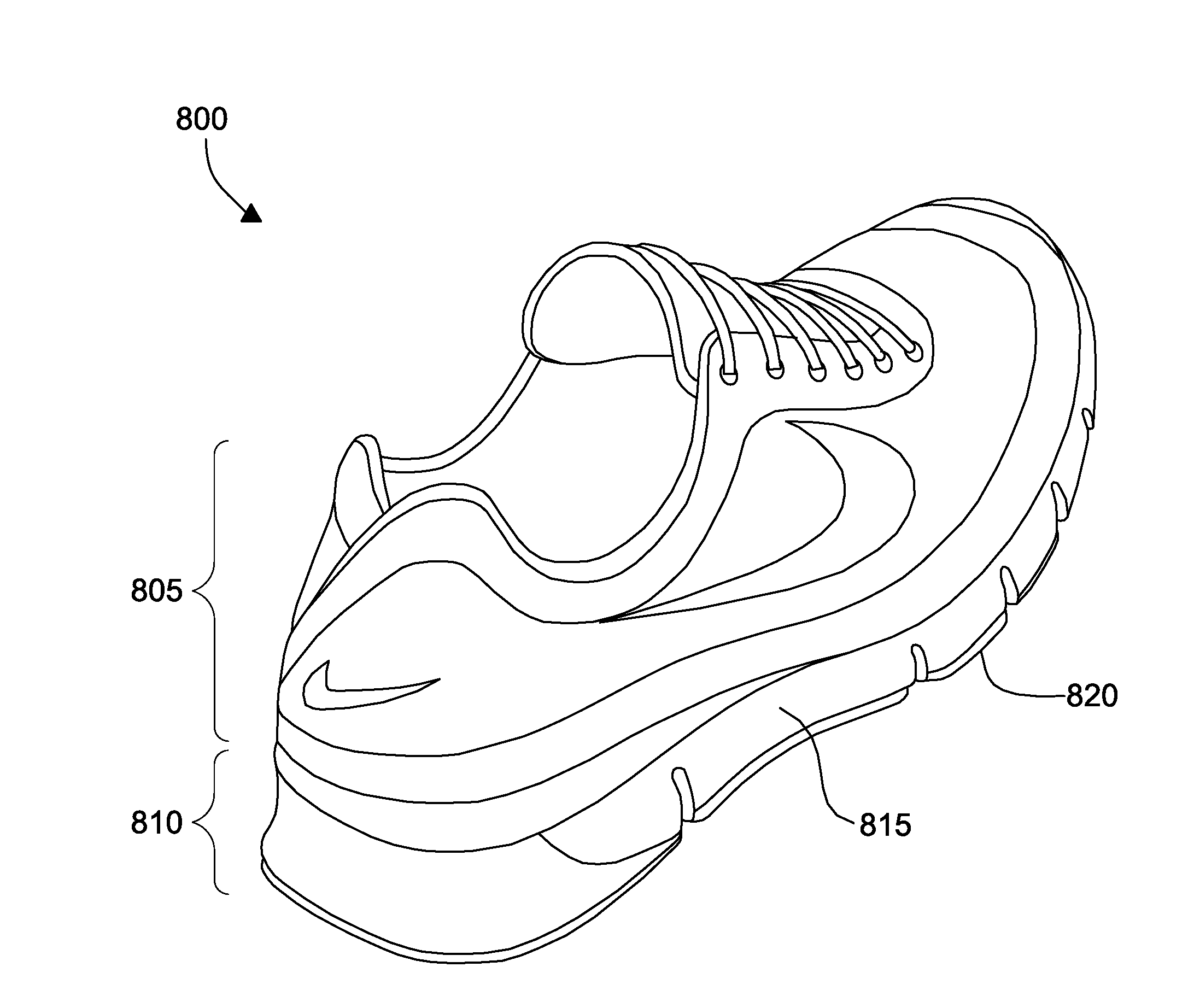

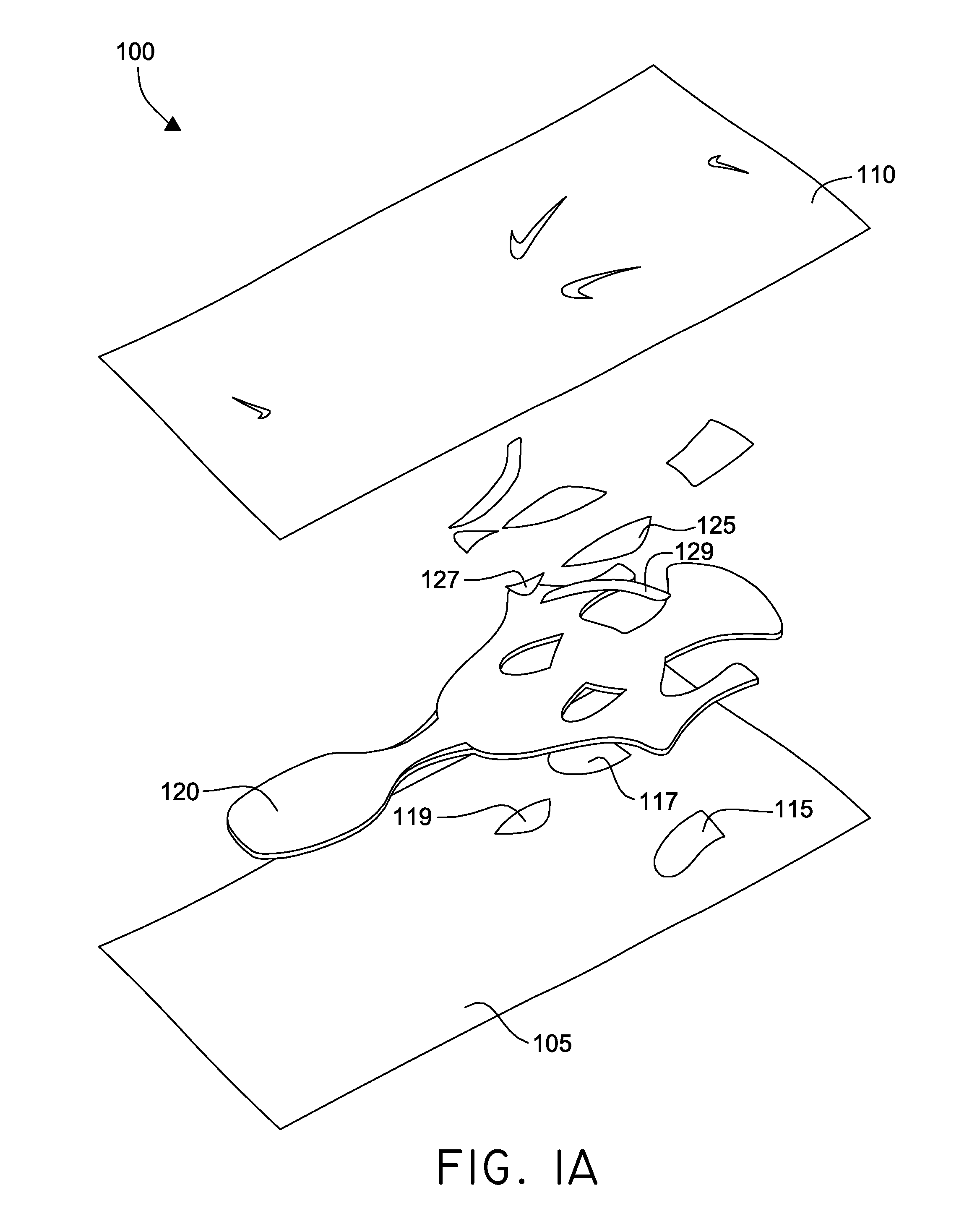

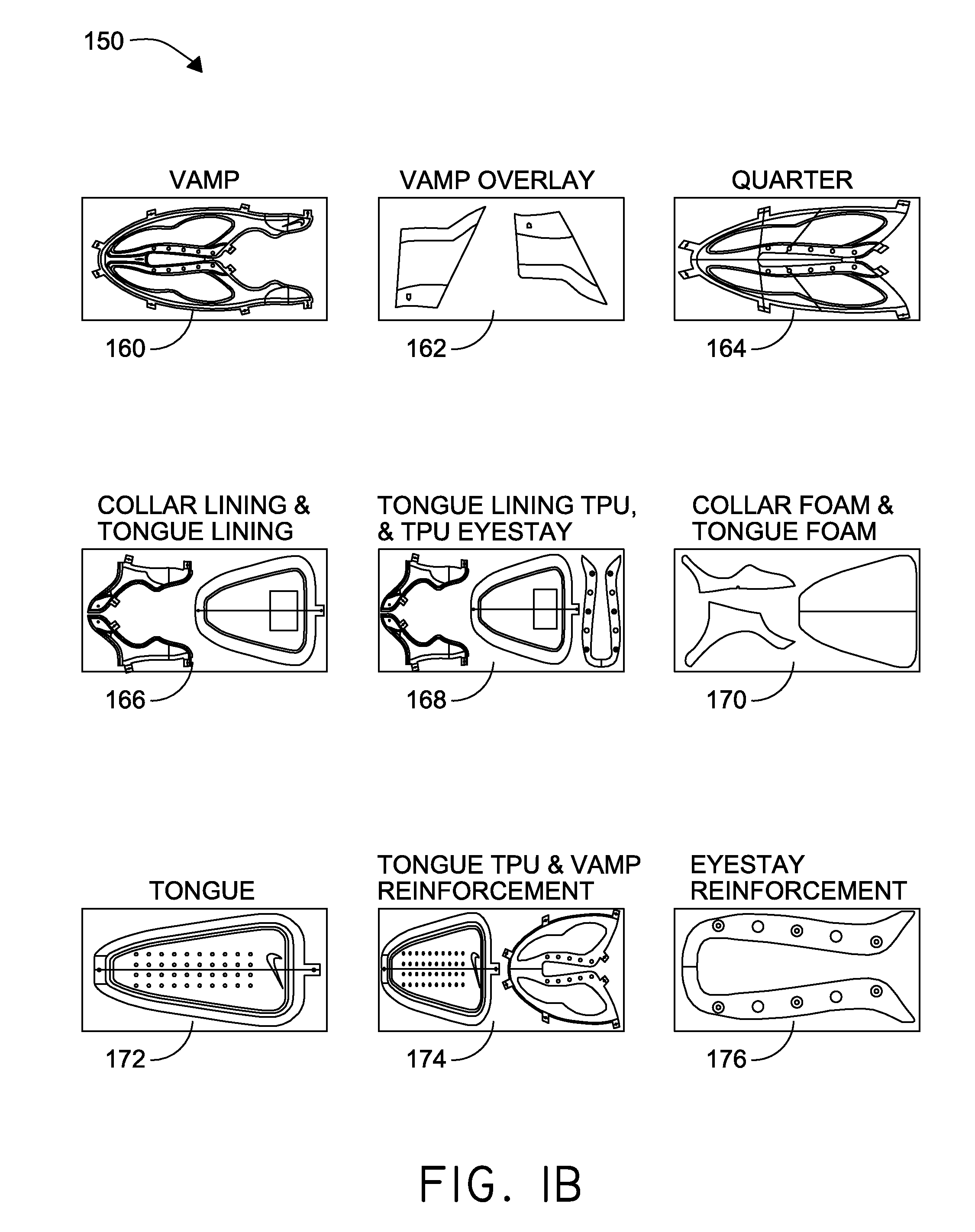

[0022]Shoes in accordance with the present invention are designed to enable the efficient manufacturing of customized shoes. Shoe model options in accordance with the present invention may include, for example, a running shoe model and a basketball shoe model, although other shoes in accordance with the present invention may be constructed. In accordance with the present invention, upper forms of shoes are manufactured by a flat forming process, whereby the upper pattern is kept in a two-dimensional shape for most of the upper assembly and then stitched, glued, molded or otherwise affixed into a three dimensional form in the final stage of upper assembly. Shoes having midsoles providing heel support in accordance with the present invention may utilize traditional uppers fabricated from a plurality of pieces, although the specific example described herein further includes a flat formed upper to achieve additional construction efficiencies. The flat forming process minimizes the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com