Weld-on cast carbon steel roll crusher tooth having silver-brazed tungsten carbide inserts on wear surfaces

a technology of tungsten carbide inserts and roll crusher teeth, which is applied in the direction of grain treatment, manufacturing tools, and so on, can solve the problems of significant damage to the joint integrity, and achieve the effect of minimizing damage to the inserts and softening impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

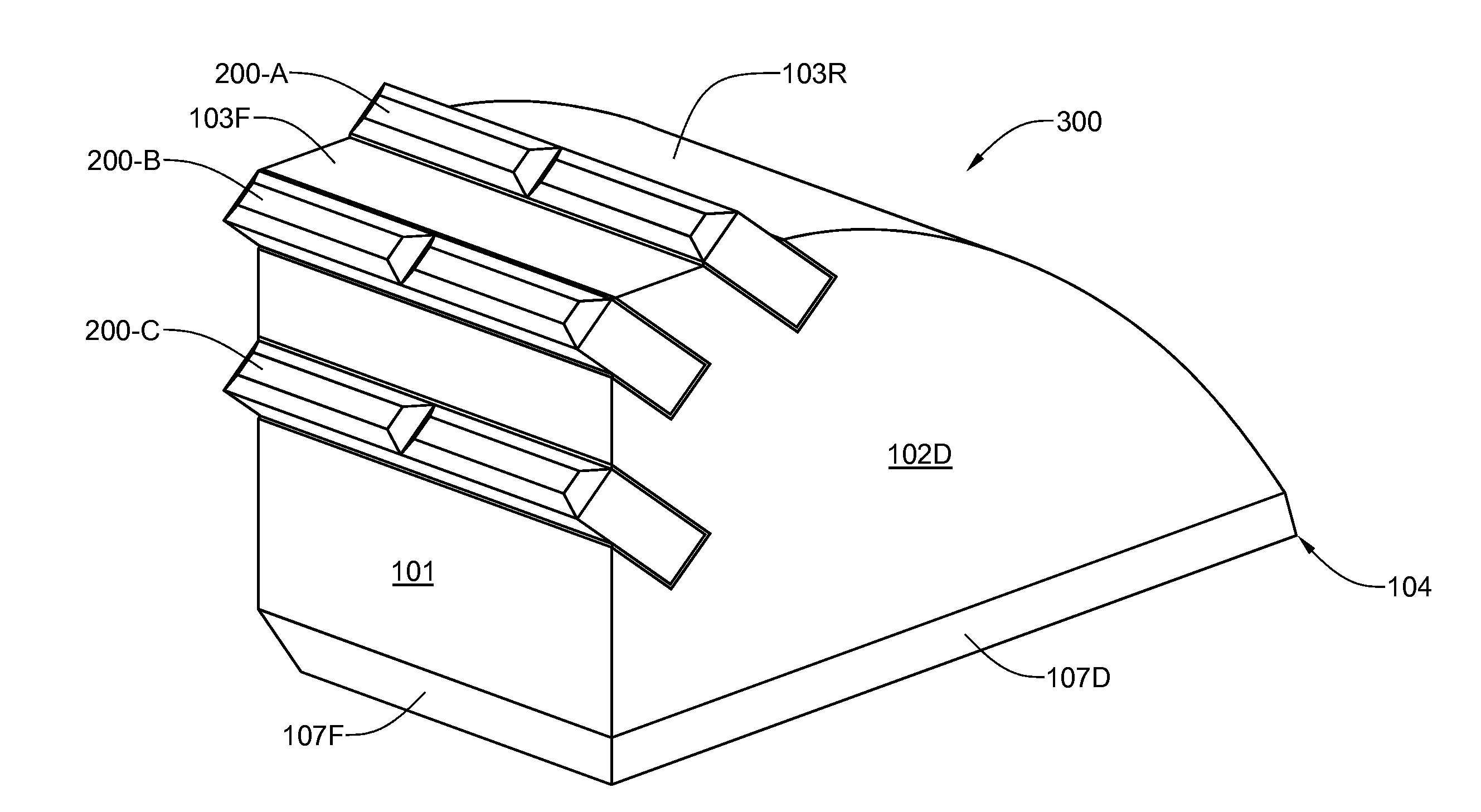

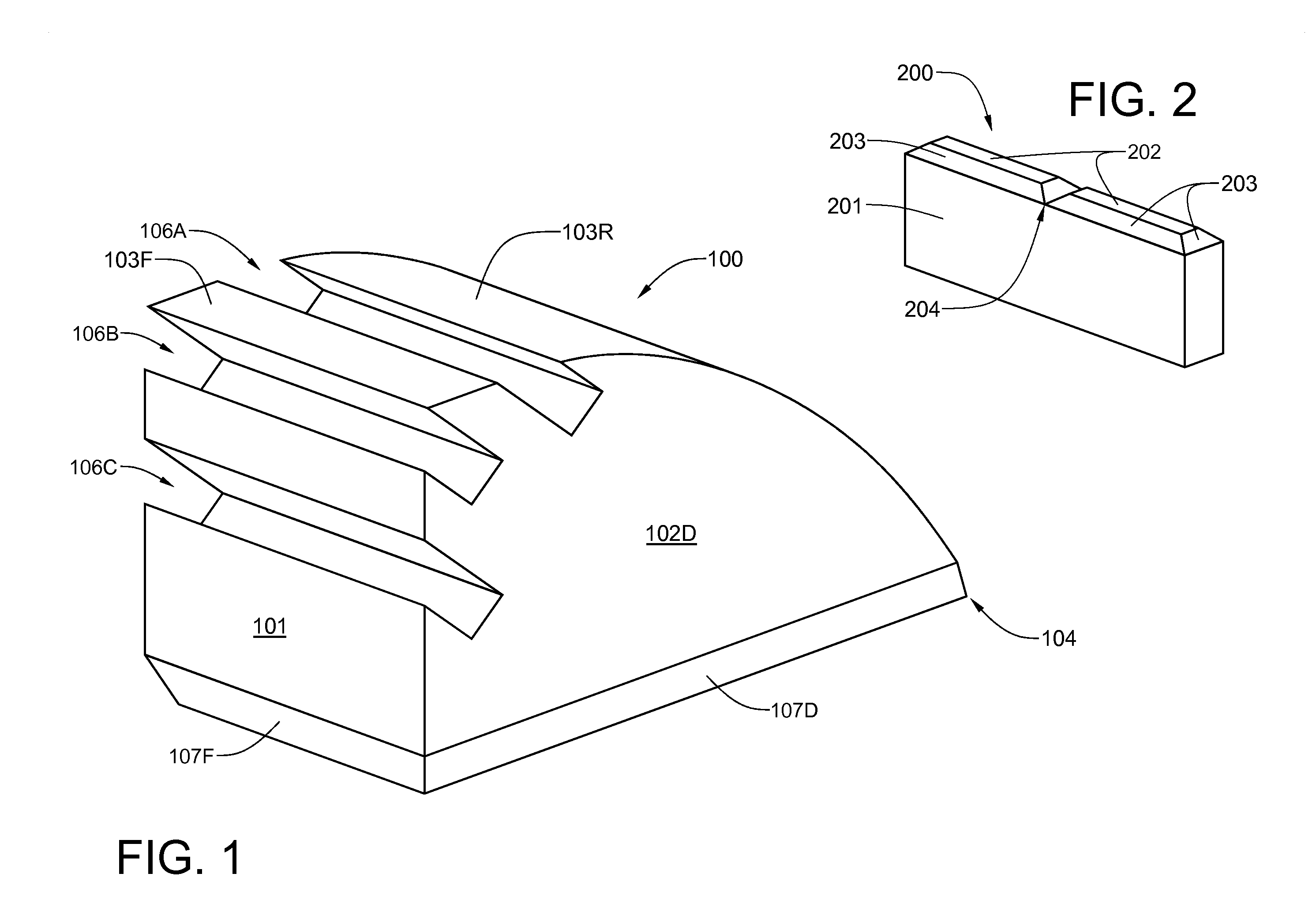

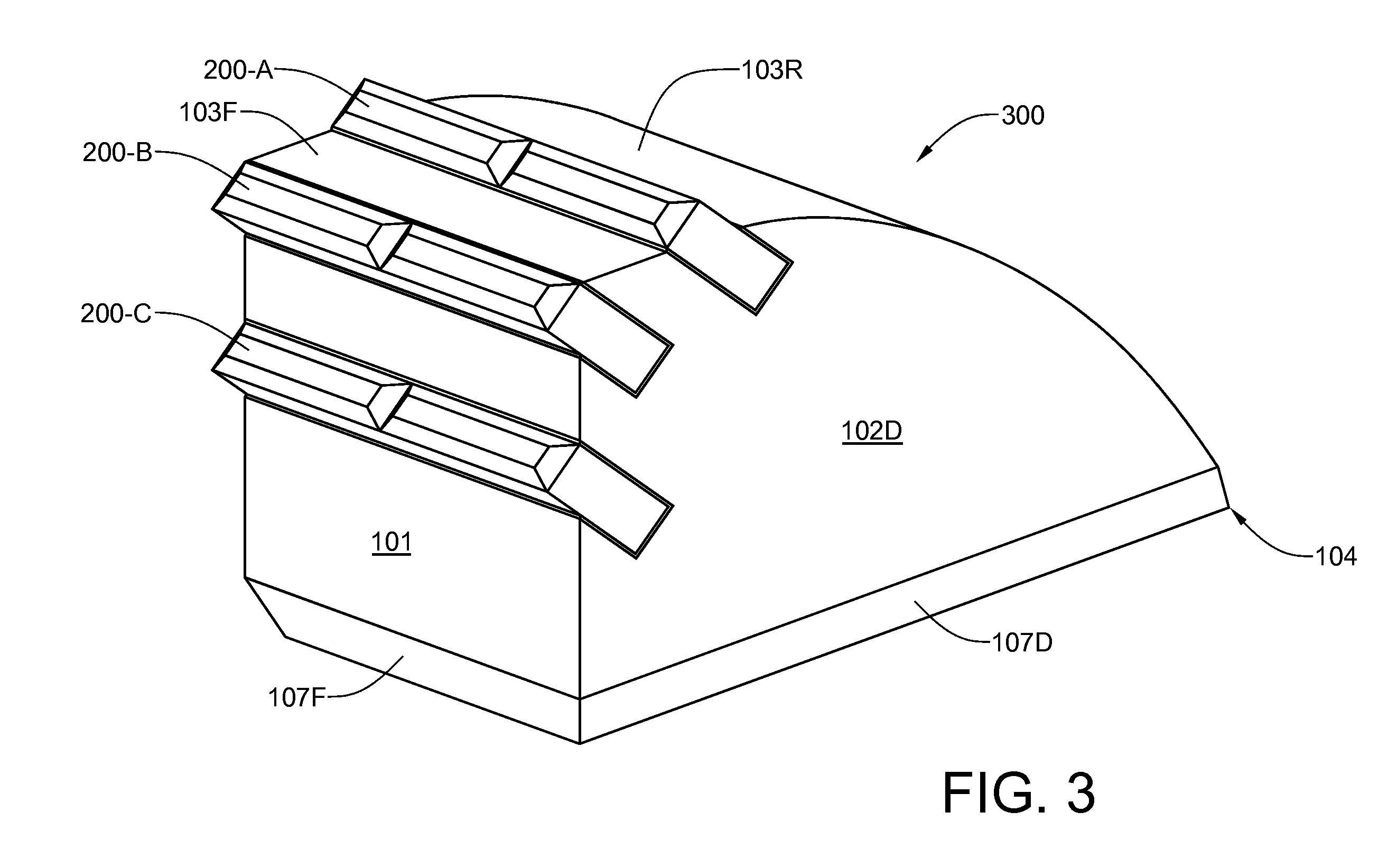

[0028]The invention will now be described with reference to the attached drawing FIGS. 1 through 8. It should be understood that although the drawings are intended to be merely illustrative, a reasonable attempt has been made to provide drawings which are close to scale.

[0029]Referring now to FIG. 1, a tooth body 100 is cast from #7018 high-carbon steel. It will be noted that the tooth body 100 has a vertical, generally planar front face 101; a vertical, generally planar right-side face 102D; an upper surface 103 that has a generally planar forward portion 103F and a simple-curved rear portion 103R that begins at the level of the planar forward portion 103F, and transitions so as to make an acute-angled rear edge 104 with a planar lower surface 701 (please refer to the bottom plan view of FIG. 7). The left-side face 102S (please refer to FIG. 5) is a vertical, generally planar surface and a mirror image of the right-side face102D. For a preferred embodiment of the invention, the cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com