Pre-stressed bore barrel and related manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

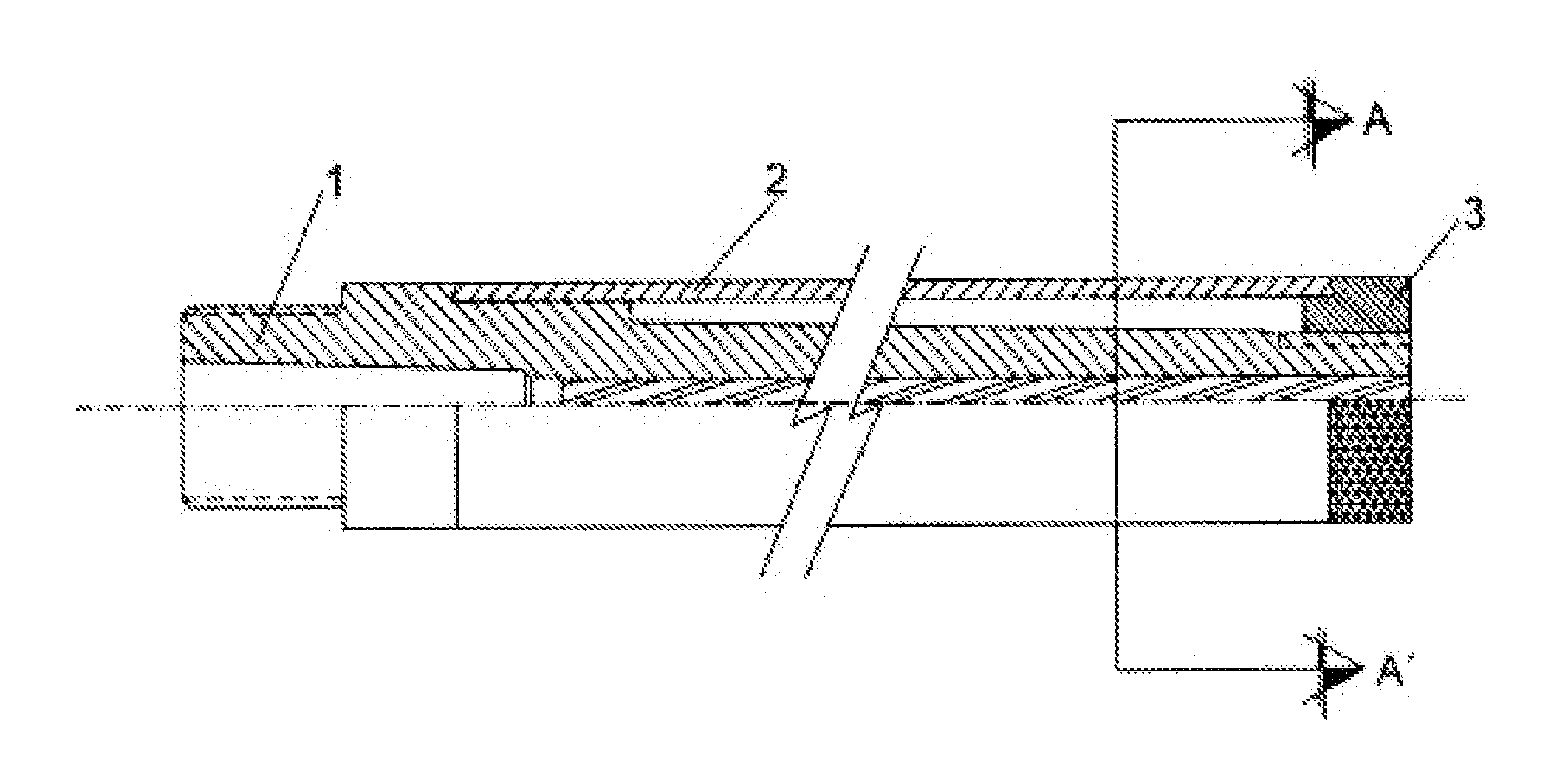

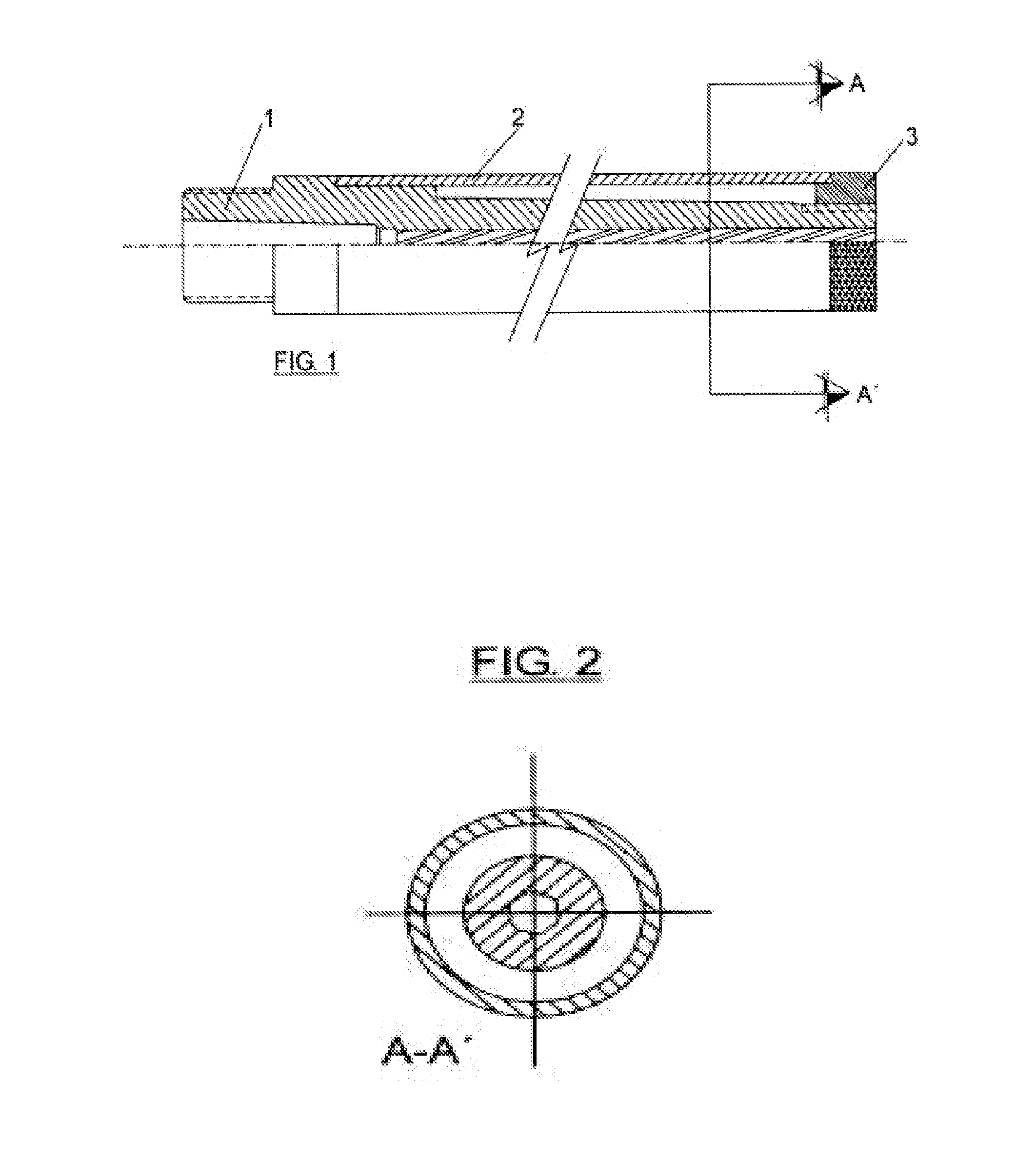

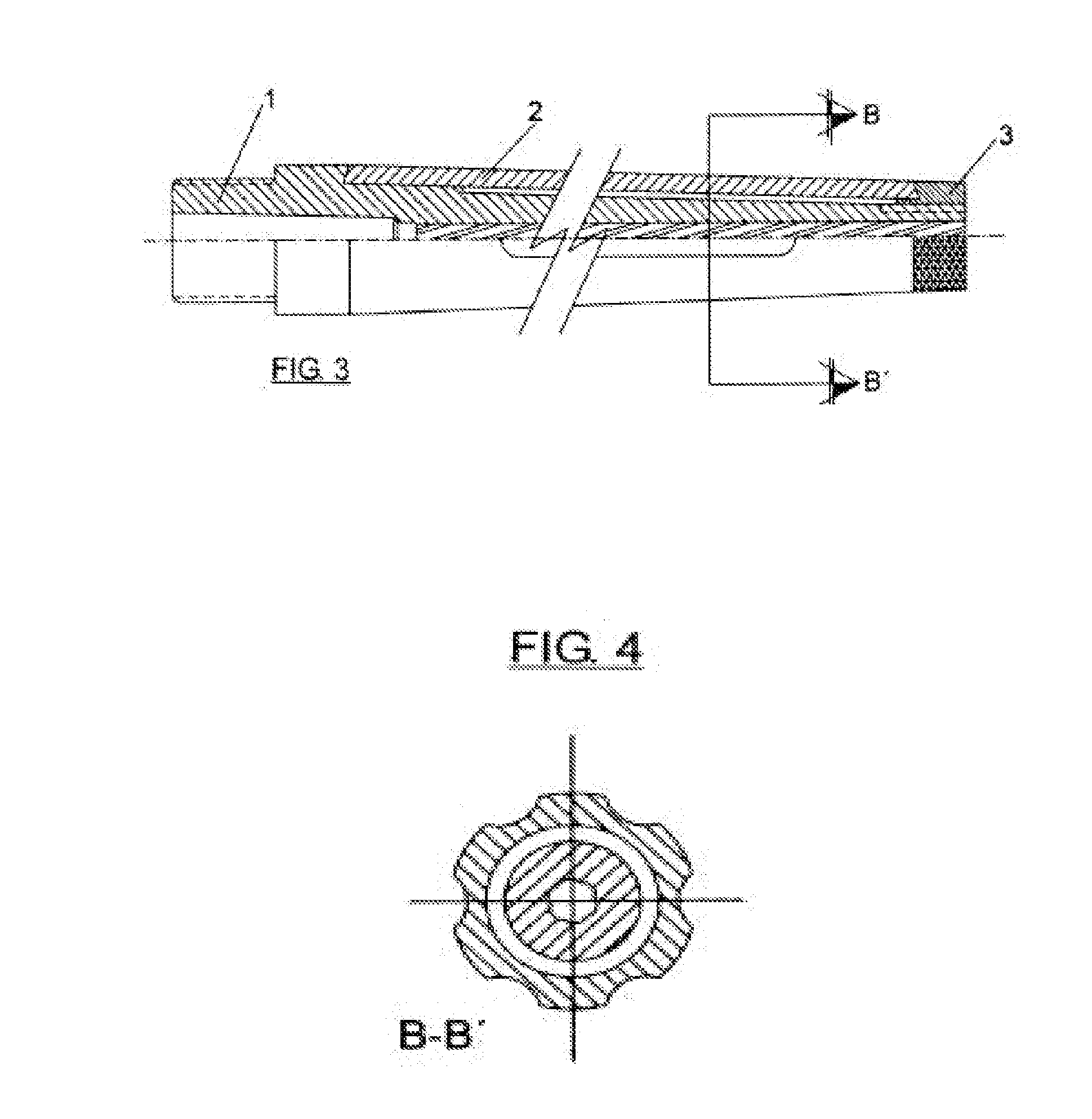

[0038]A barrel of a pre-strained gunbore is shown in FIGS. 1, 3, 5, 7 and 8 which comprise a rifled gunbore (1) on which there is an outer sleeve (2) mounted coaxially on the exterior thereof with a high moment of polar inertia. The outer sleeve (2) is fitted to one side of the rifled gunbore (1), whereas it is fixed on the opposite side to said rifled gunbore (1) via a screwed union (3).

[0039]FIGS. 1 and 3 show transverse sectional views of two barrels barrel of pre-strained gunbores, with their respective straight and inclined profile outer sleeves. In the same manner, the transverse views can be seen in FIGS. 2 and 4.

[0040]As can be seen in FIGS. 5 and 6, the rifled gunbore (1) disposes two holes (5, 6), disposed in proximity to the extreme in which the screwed union (3) is disposed, and the holes are disposed diametrically opposite to each other. An annular air-filled chamber 4 is defined between the components described and is hermitically sealed from the exterior.

[0041]Said ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com