Using Carbon Dioxide Regulators to Extend the Shelf Life of Plastic Packaging

a technology of carbon dioxide regulator and plastic packaging, which is applied in the direction of container/bottle contruction, rigid containers, volume measurement, etc., can solve the problems of difficult to maintain cosub>2 /sub>pressure, product is no longer suitable for use, and thinner bottles lose carbonation more quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051]Various carbon dioxide regulators, specifically organic carbonates, were tested to determine whether they could be activated by water vapor alone and without an organic acid present. The results shown in FIG. 7 illustrates that water vapor activates CO2 production from organic carbonates by hydrolysis and an organic acid is not necessary.

example 2

[0052]A variety of liner materials were tested to determine the effect of the permeability of the liner material on the rate of CO2 production. A mixture of sodium bicarbonate and citric acid was sealed in a pouch suspended above 25 mL of water in a sealed bottle. The pouches were fabricated from three different materials with different permeabilities to moisture: a paper tea bag, polylactic, acid and polyethylene. The results in FIG. 8 demonstrates that a very low moisture barrier allows the most rapid rate of CO2 generation and the higher moisture barrier provided by the polyethylene provides the slowest rate. Thus, a moisture barrier material between the carbon dioxide regulator composition and the carbonated beverage can be used to control the rate of CO2 production.

example 3

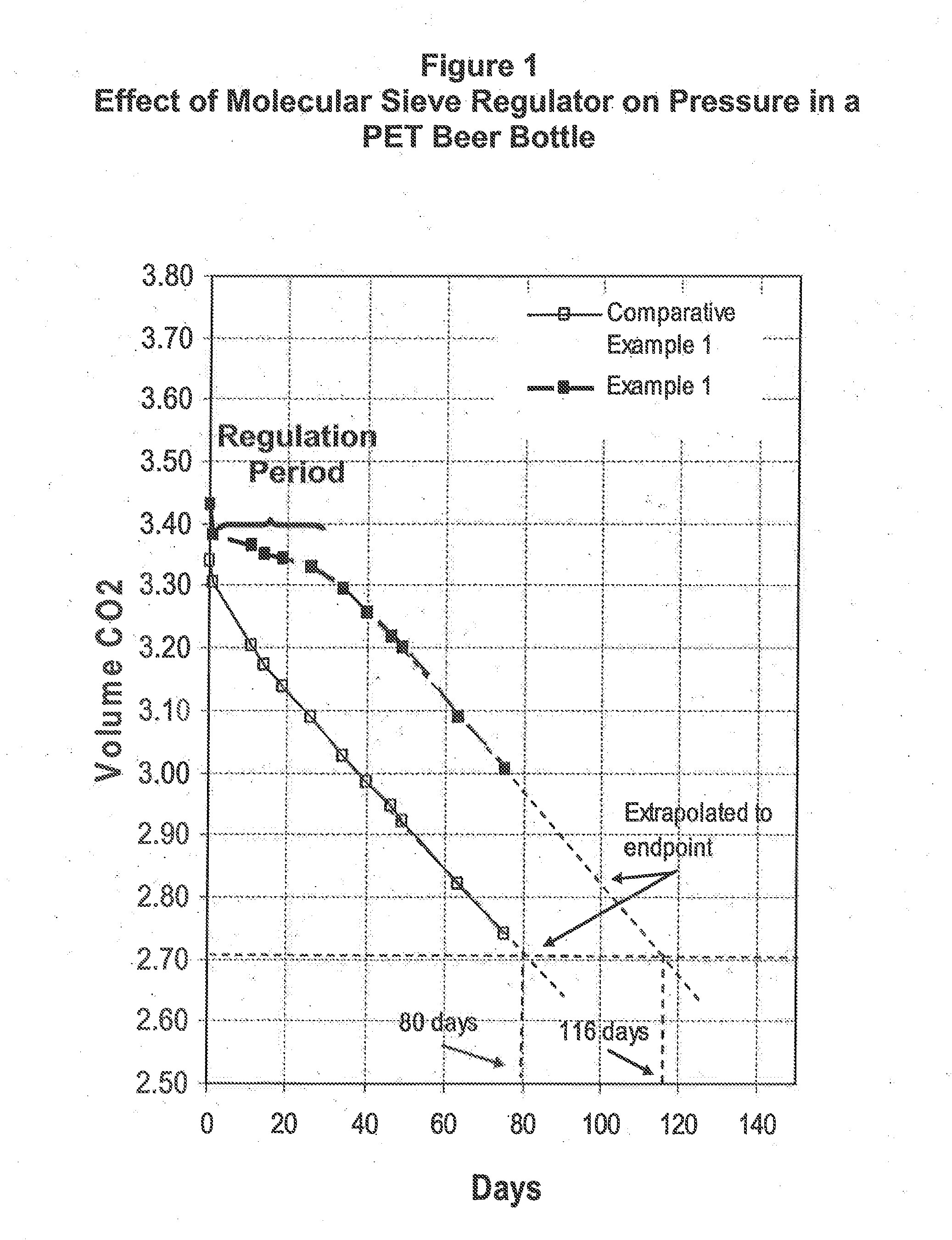

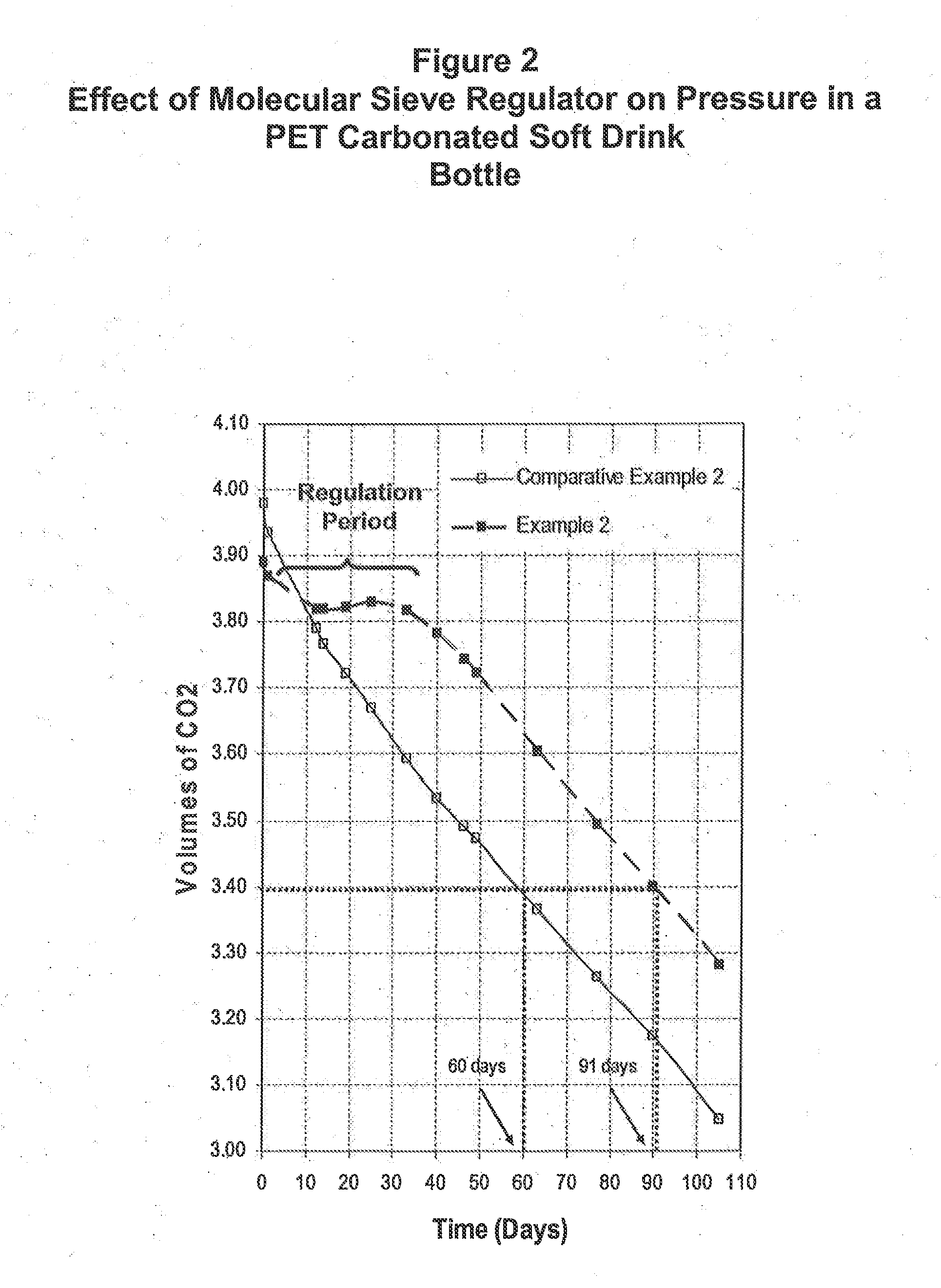

Sorbent CO2 Saturation and Release

[0053]Various carbon dioxide generators, in particular sorbent materials, were tested to determine their capacity to store and release CO2 under high pressure and to thereby extend the shelf-life of a carbonated beverage. The selected sorbent materials were first saturated under a high pressure CO2 environment. The sorbent materials were then placed into 20 oz bottles and the bottles were rapidly carbonated with dry ice and capped. The molecular sieves were obtained from commercial sources and either used as received or dried by heating under vacuum. The 13X molecular sieve discussed below was obtained from the Aldrich Chemical Company and either used as received or dried under vacuum prior to use. The rate of CO2 loss from the bottles was recorded over time. The results are shown below in Table 3:

TABLE 3Summary of the CO2 Saturation Experiments% Shelf-LifeSampleImprovementControl Bottles (no saturated additives)—Bottles w / 8416 saturated film32.6%Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com