Recuperation system for underwater cleaning operations

a technology for cleaning operations and recovery systems, which is applied in the direction of vessel cleaning, hulls, vessel construction, etc., can solve the problems of water pollution, device to be firmly pressed or sucked to the surface, and harmful effects of biological growth on the fuel consumption of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

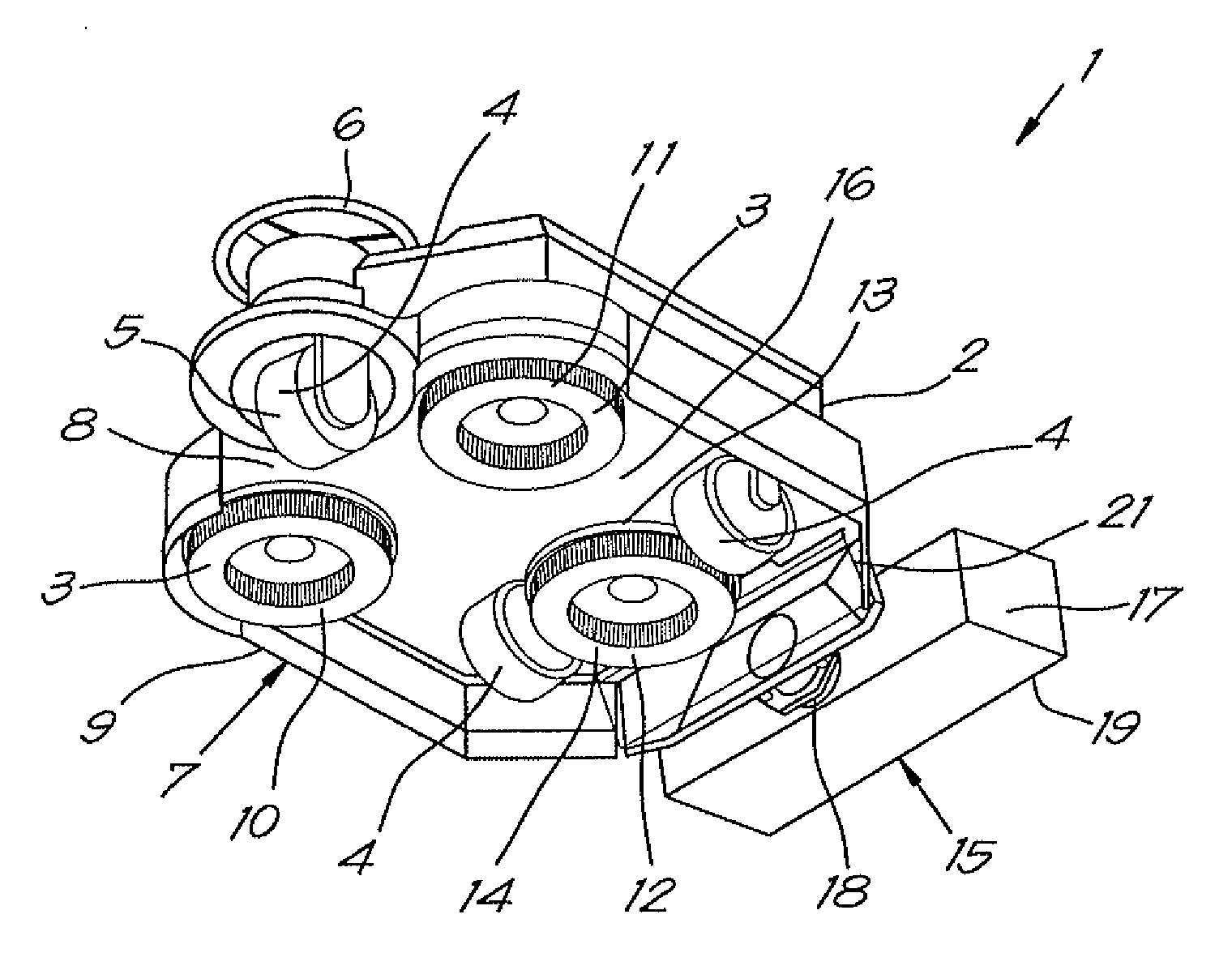

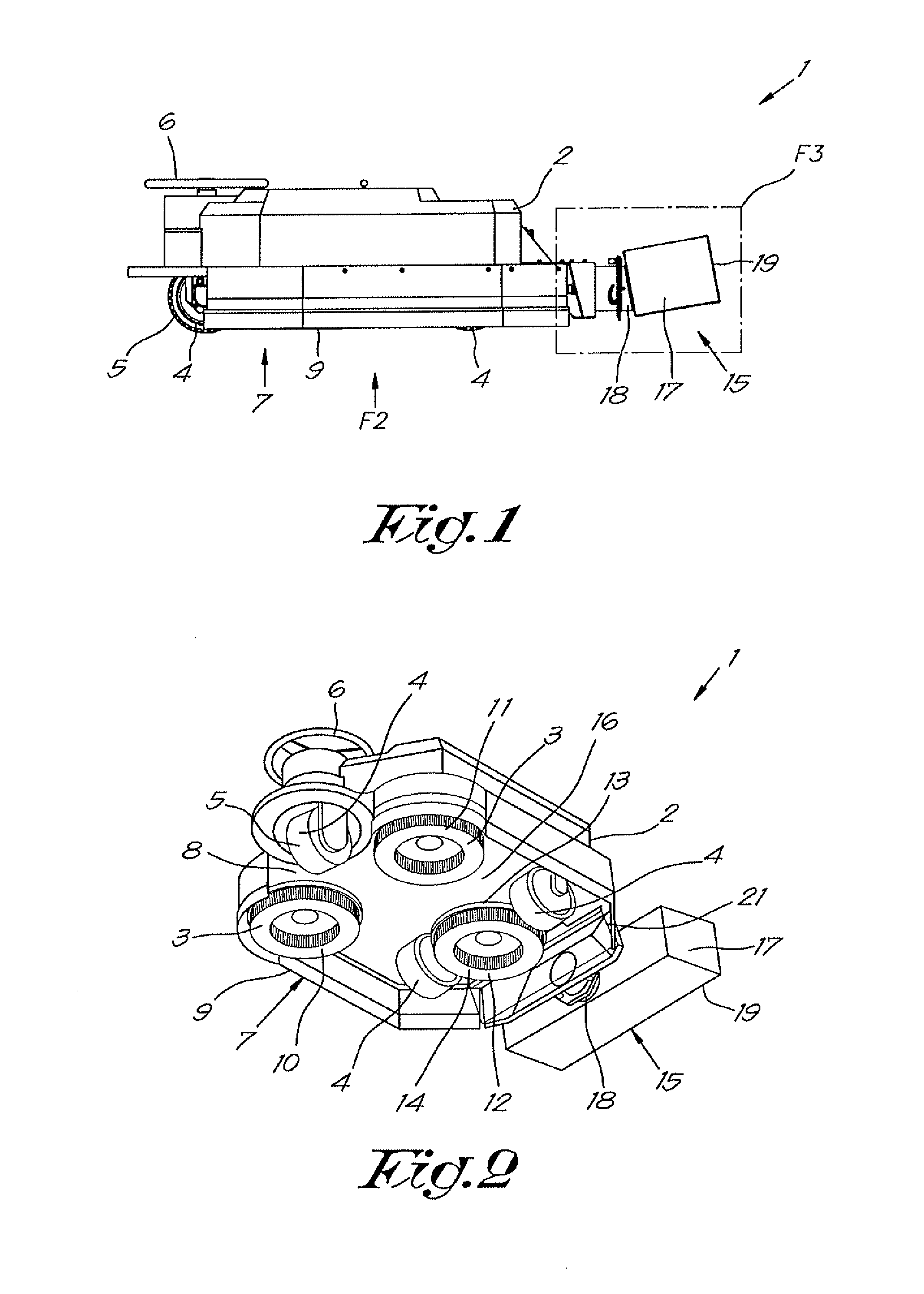

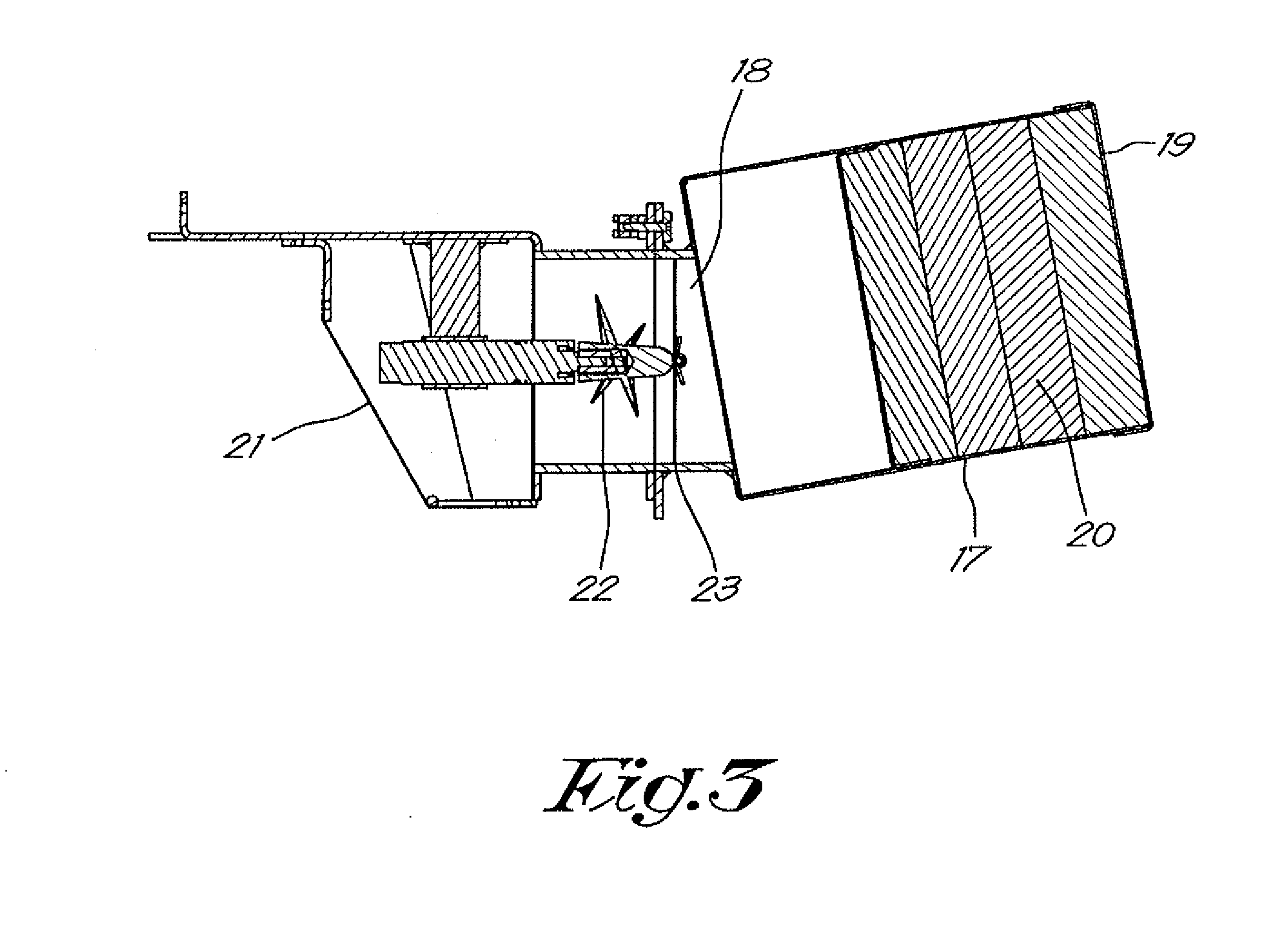

[0034]In FIG. 1 a device according to the invention is schematically represented, comprising a movable frame 2 with at least one brush 3.

[0035]For the movement of this frame 2, wheels 4 are provided on one side, namely on the side intended for making contact with the surface to be cleaned.

[0036]More specifically, three wheels 4 are provided in the embodiment of the figures, each of them being driven by a motor which isn't shown in the drawings.

[0037]This motor can be a hydraulic motor of which the flow can be adjusted by means of a valve operated by a control device.

[0038]Flow control of the hydraulic motor is thereby advantageous in that adjustment of the speed with which the device moves over the surface is possible.

[0039]In the represented variant these wheels are ordered in a triangular pattern, with a front wheel and two back wheels, whereby the front wheel acts as steering wheel 5 and can be oriented as a function of the desired displacement of the device 1 over the surface to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com