Lens barrel support structure and optical device

a technology of optical devices and support structures, applied in the direction of mountings, optics, instruments, etc., can solve the problems of increasing the number of parts, difficult to accurately attach the lens barrel to the main body of the optical device, and the strain is more likely to occur in the member during the attachment, so as to achieve effective dispersion of any force exerted and increase the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0030]1-1. Overall Configuration

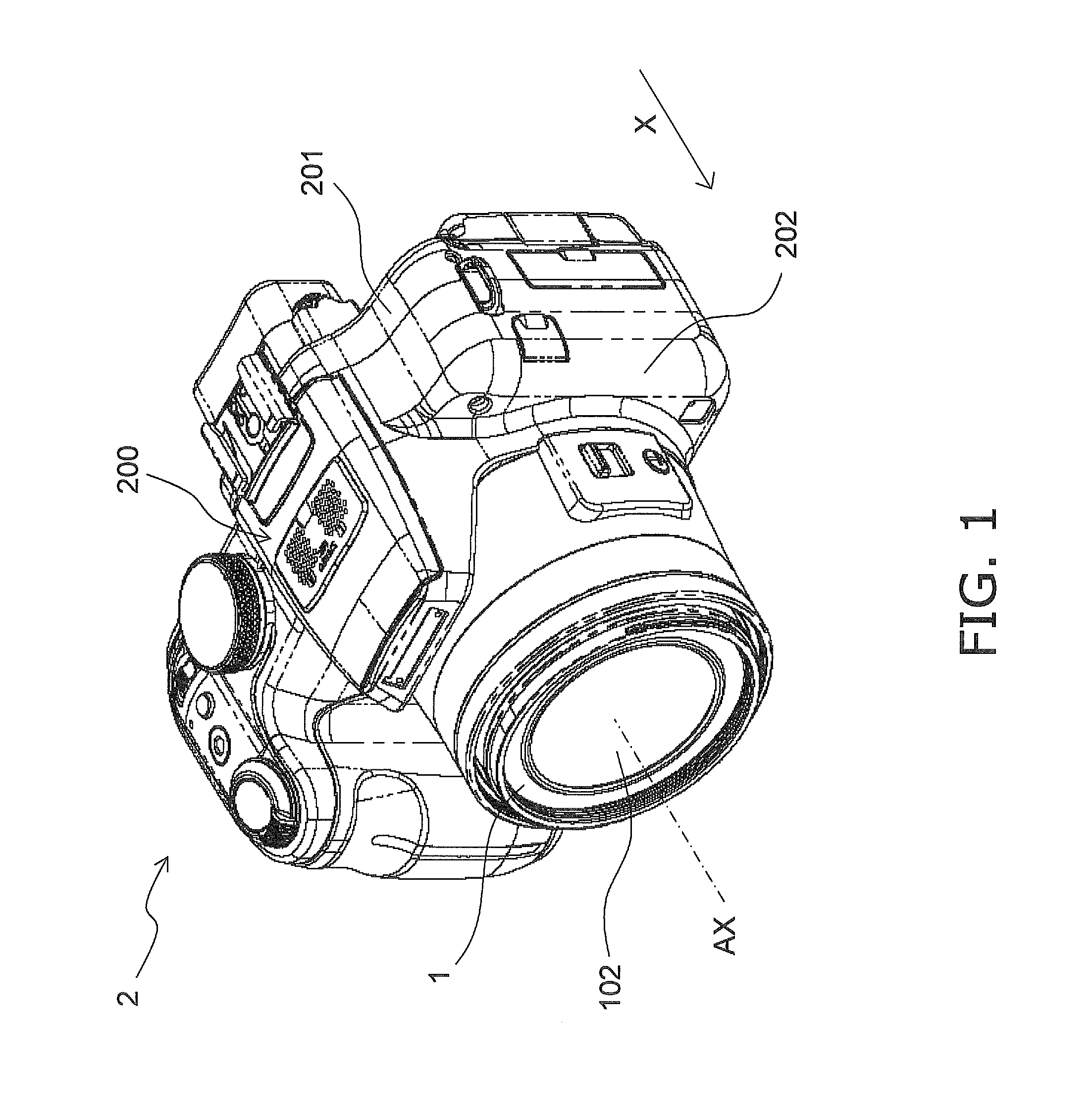

[0031]The digital camera 2 according to an embodiment of the present invention will now be described through reference to the drawings.

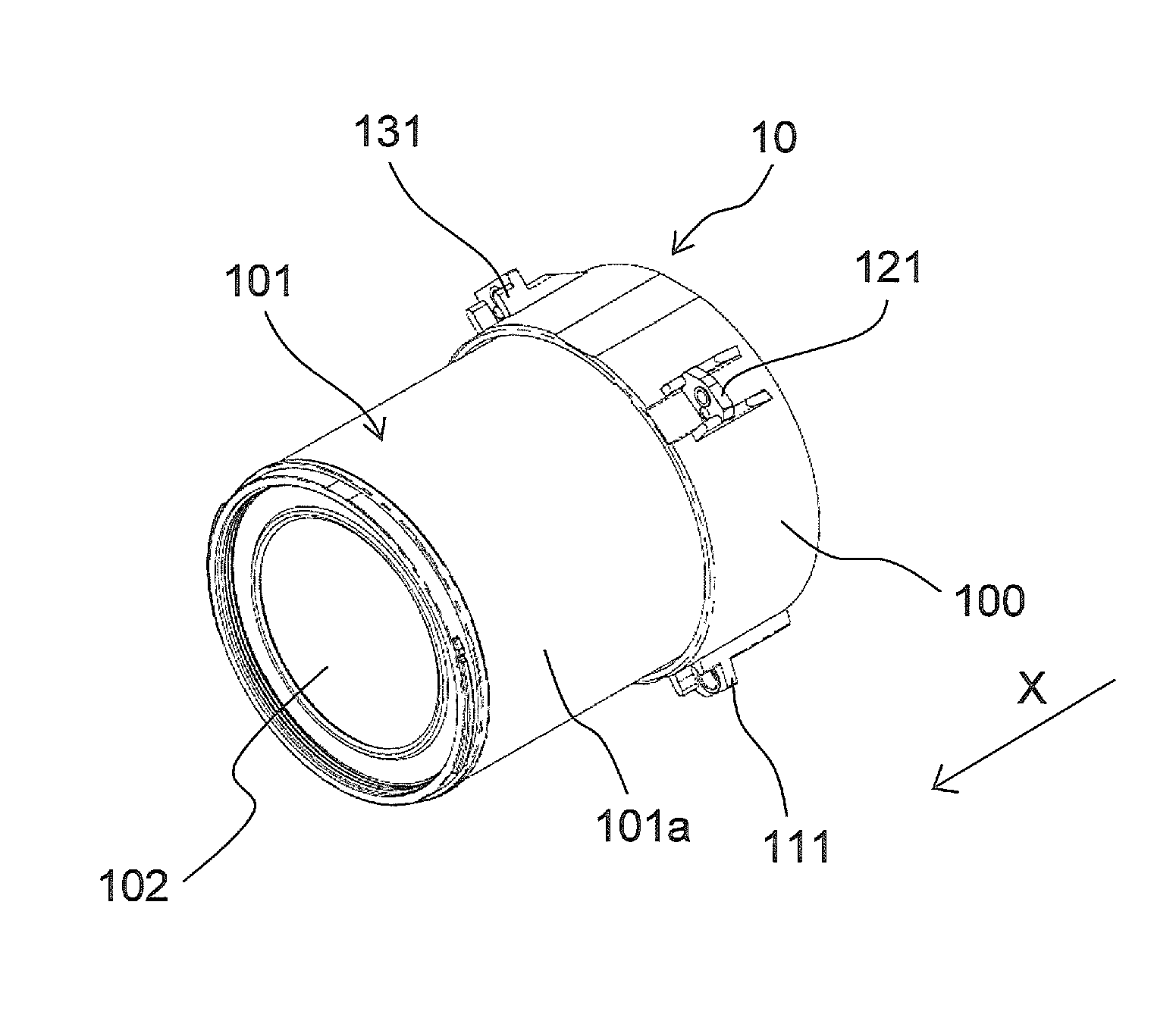

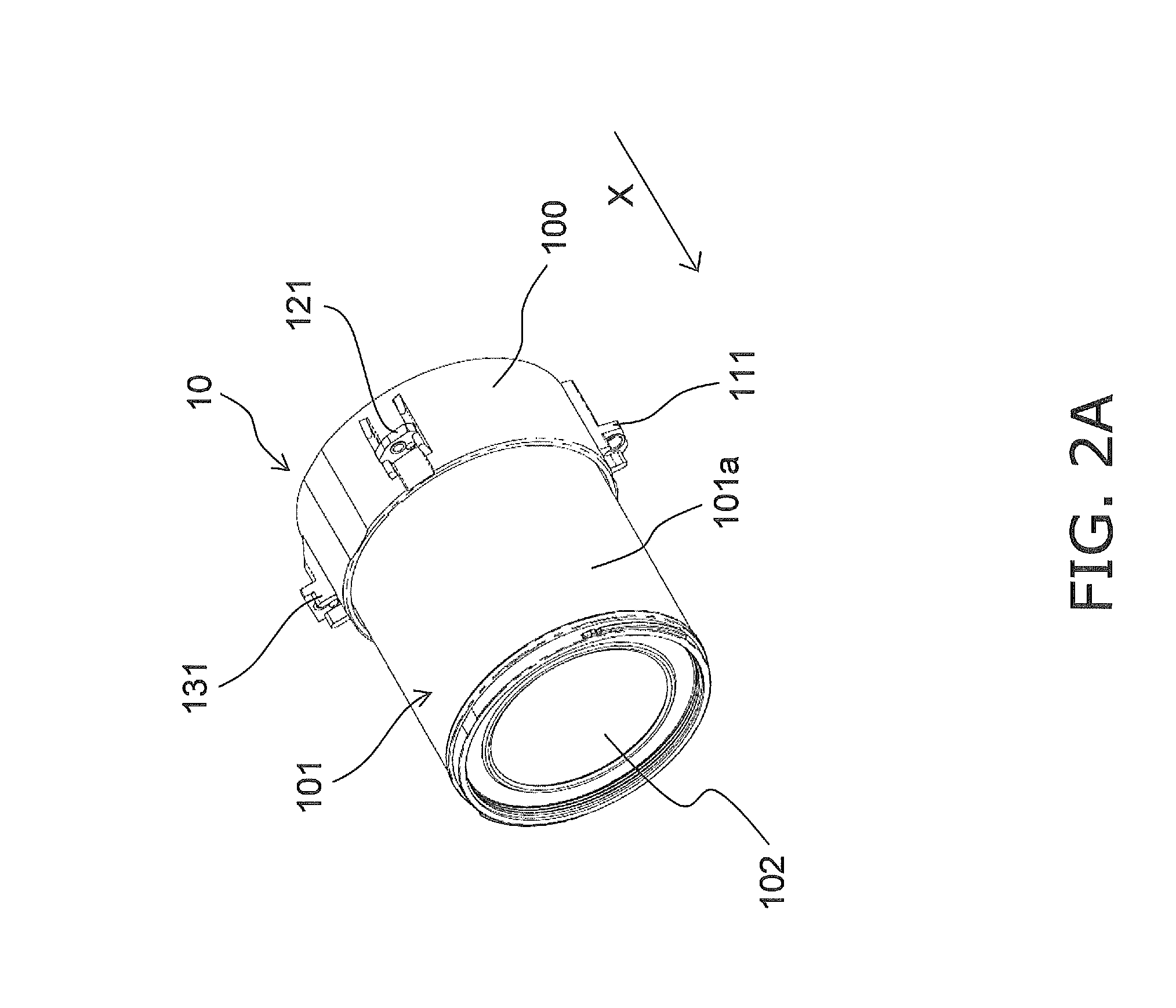

[0032]FIG. 1 is an oblique view of a digital camera 2 (an example of an optical device) in the first embodiment. In this embodiment, an optical device is described by using the digital camera 2 as an example, but the optical device can be a silver halide camera, a digital camera (electronic camera), a video camera, or any of various other such optical devices. FIGS. 2A and 2B are oblique views of the configuration of the lens barrel 1. FIG. 2C is a rear view of the configuration of the lens barrel 1. FIG. 3 is a rear view of the configuration of a front panel 202 according to the first embodiment. FIGS. 4A and 4B are oblique views of the state prior to the attachment of the lens barrel 1 to the front panel 202. FIG. 5 is a rear view of the lens barrel 1 attached to the front panel 202. FIGS. 6A and 6B are cross section...

second embodiment

[0080]FIG. 7 is a cross section of the main components in a lens barrel support structure 4 according to a second embodiment. Those portions having substantially the same function as in the first embodiment will be numbered the same, and redundant descriptions will be omitted. The support structure 4 according to this second embodiment is characterized by the configuration of a stopper 411. The stopper 211 according to the first embodiment had the protrusion 211b and the fourth screw 311, but the stopper 411 according to the second embodiment has a stepped screw 312.

[0081]The stopper 411 has a base portion 411c (an example of a first limiter), a fourth threaded hole 411a, and the stepped screw 312.

[0082]The stepped screw 312 has a first head 312a (an example of a second limiter), a cylindrical non-threaded part 312b (an example of a trunk part, and an example of a third limiter) extending from the first head 312a, and a cylindrical threaded part 312c extending from the non-threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com