Robot cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

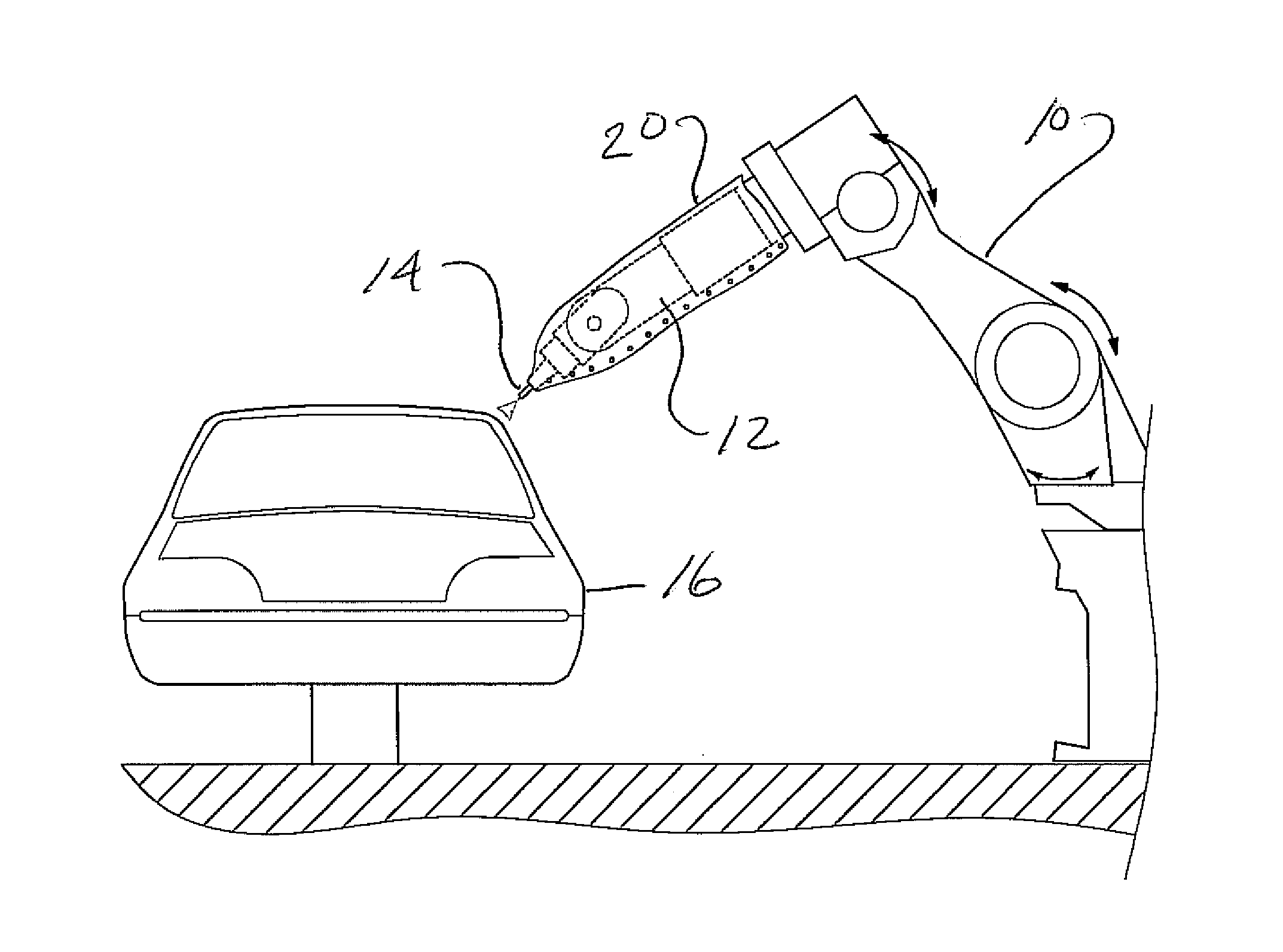

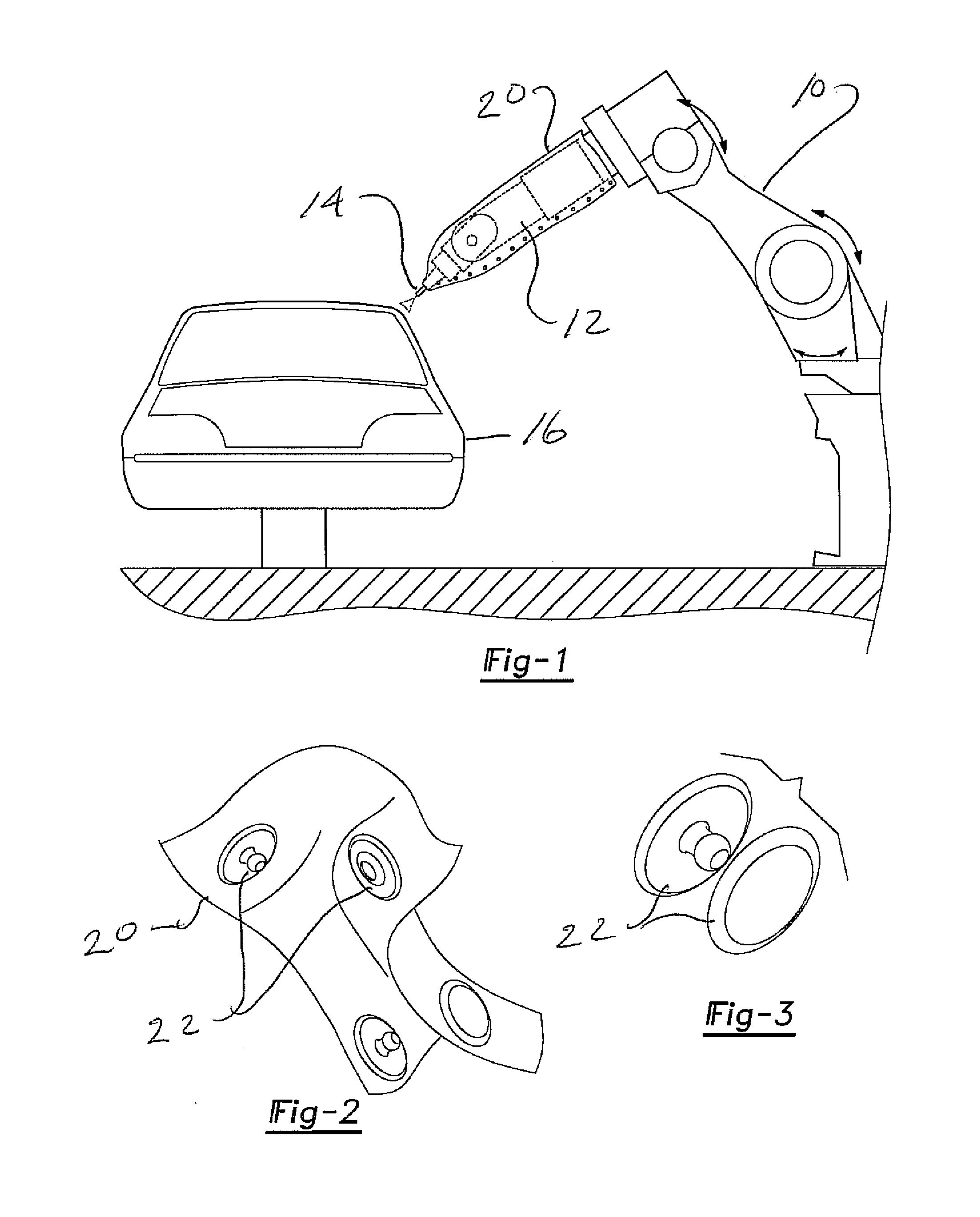

[0020]With reference first to FIG. 1, an exemplary robot 10 is illustrated having a manipulator arm 12. A paint spray gun 14 is carried by the manipulator arm 12 which manipulates the paint spray gun to spray the desired amount of paint in the desired pattern on a component 16. The component 16, furthermore, may be any type of component, such as an automotive vehicle, a component for an automotive vehicle, or other types of products.

[0021]Still referring to FIG. 1, not all of the paint from the paint spray gun 16 adheres to the component 16 during the paint spray operation. Instead, a portion of the paint spray from the paint spray gun 16 during the paint spray operation bounces or blows back from the product during the paint spray operation back toward the robot itself. Likewise, in the event that there are multiple robots paint spraying the component at the same time, any overspray from one robot may be directed toward the other robot or robots.

[0022]In order to prevent the robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com