System and method for treating sludge through combination of thermal hydrolysis and anaerobic digestion

An anaerobic digestion and thermal hydrolysis technology, which is applied in the field of sludge and organic waste treatment, can solve the problems affecting the process stability of the incineration process, the resource utilization method is not high, and the reduction effect is discounted, so as to achieve the realization of resource utilization. treatment, reduce primary energy consumption, and improve the effect of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

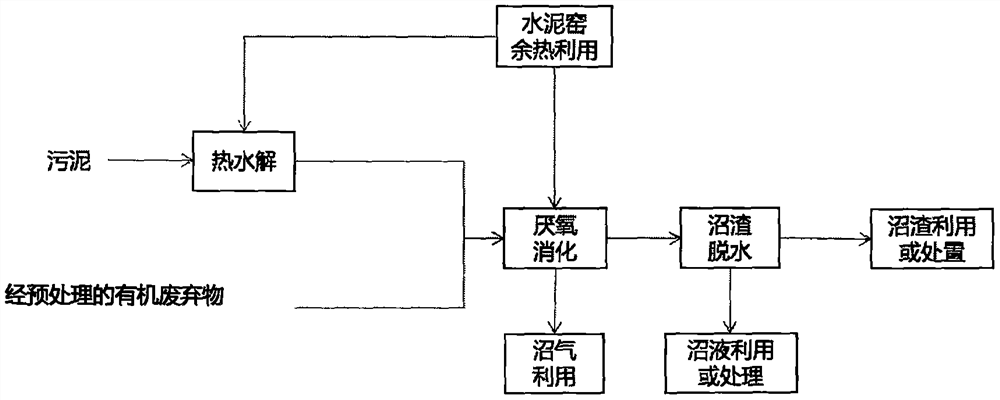

[0074] A method for thermal hydrolysis combined with anaerobic digestion and cement kiln waste heat treatment of sludge and organic waste, comprising the following steps:

[0075] Step S1. Waste heat recovery, the cement kiln waste heat utilization device provides waste heat resources of the cement kiln, and the waste heat resources are used as heat sources for the thermal hydrolysis treatment device and the anaerobic digestion device, and are used by the thermal hydrolysis treatment device and the anaerobic digestion device; waste heat resources Selected from kiln head flue gas;

[0076] Step S2. Thermal hydrolysis pretreatment, the thermal hydrolysis treatment device in the sludge thermal hydrolysis pretreatment device performs thermal hydrolysis pretreatment on the sludge, and the moisture content of the sludge is 85%; the thermal hydrolysis treatment device The heat source comes from the cement kiln waste heat utilization device; the operating temperature of the sludge the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com