Sanitary Napkin with Braid

a technology of sanitary napkin and braid, which is applied in the field of sanitary napkin, can solve the problems of reducing the absorbency of the cloth, and not being able to prevent the pad from bunching, etc., and achieves the effects of minimizing bulk, maximizing absorbency, and minimizing bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Pad Structure

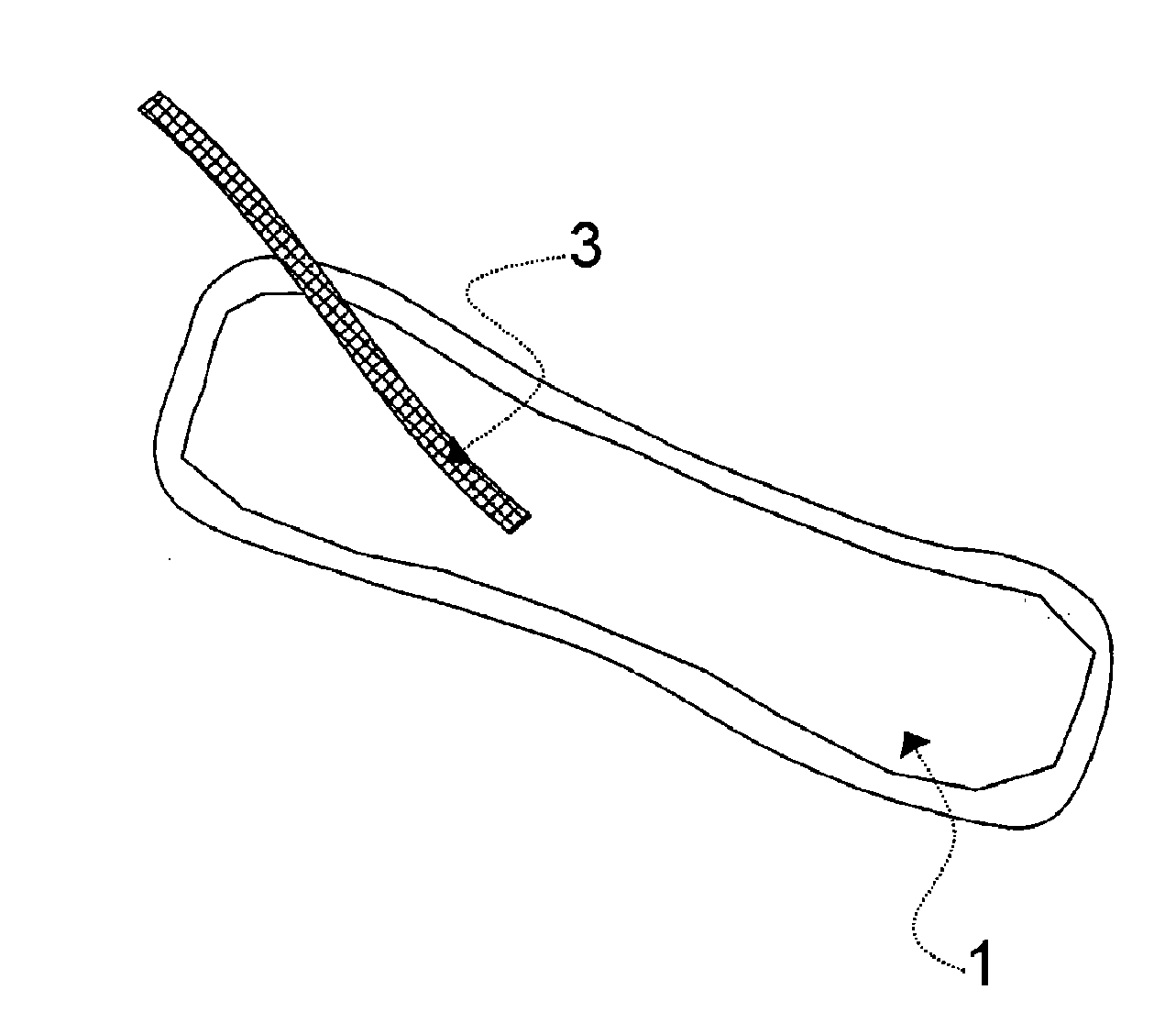

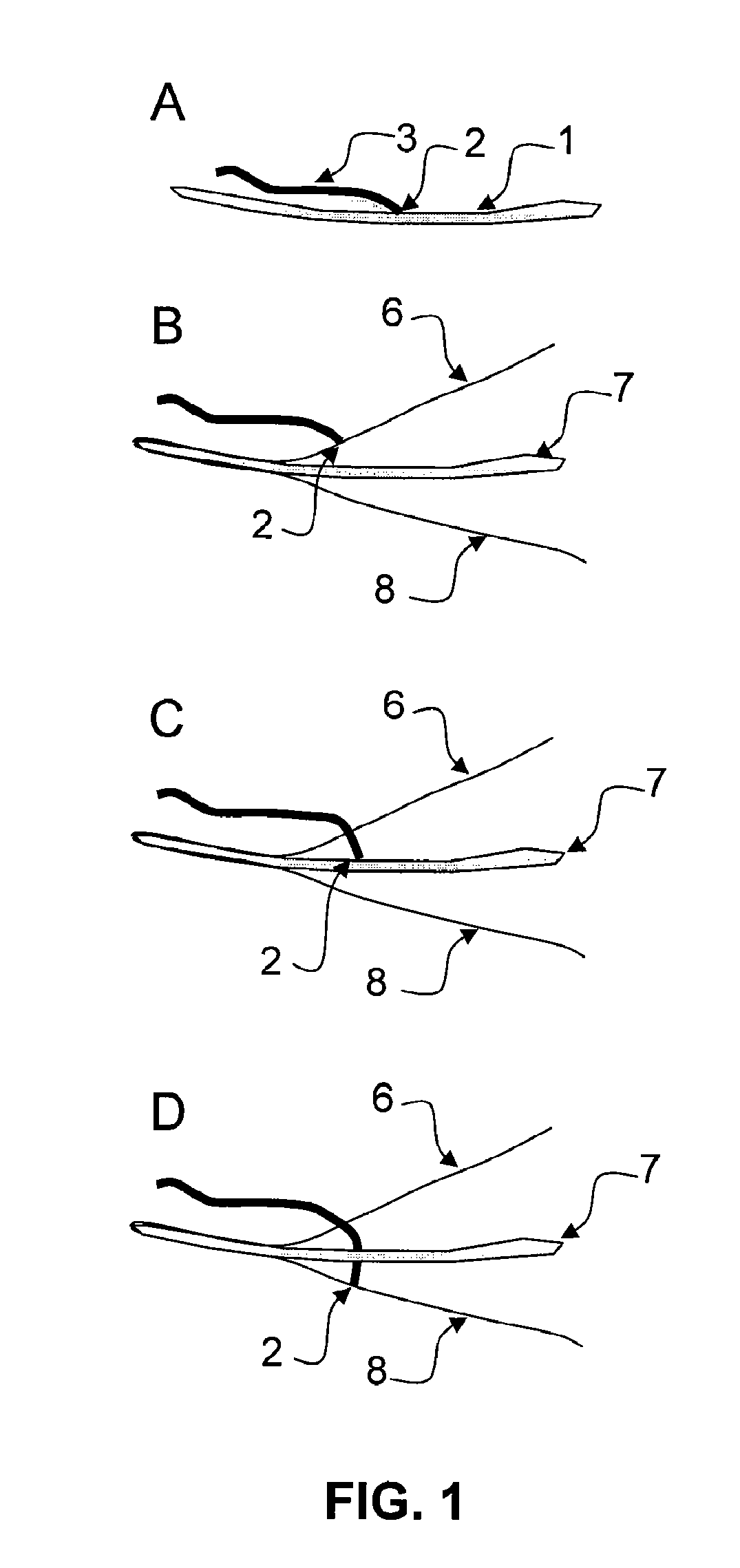

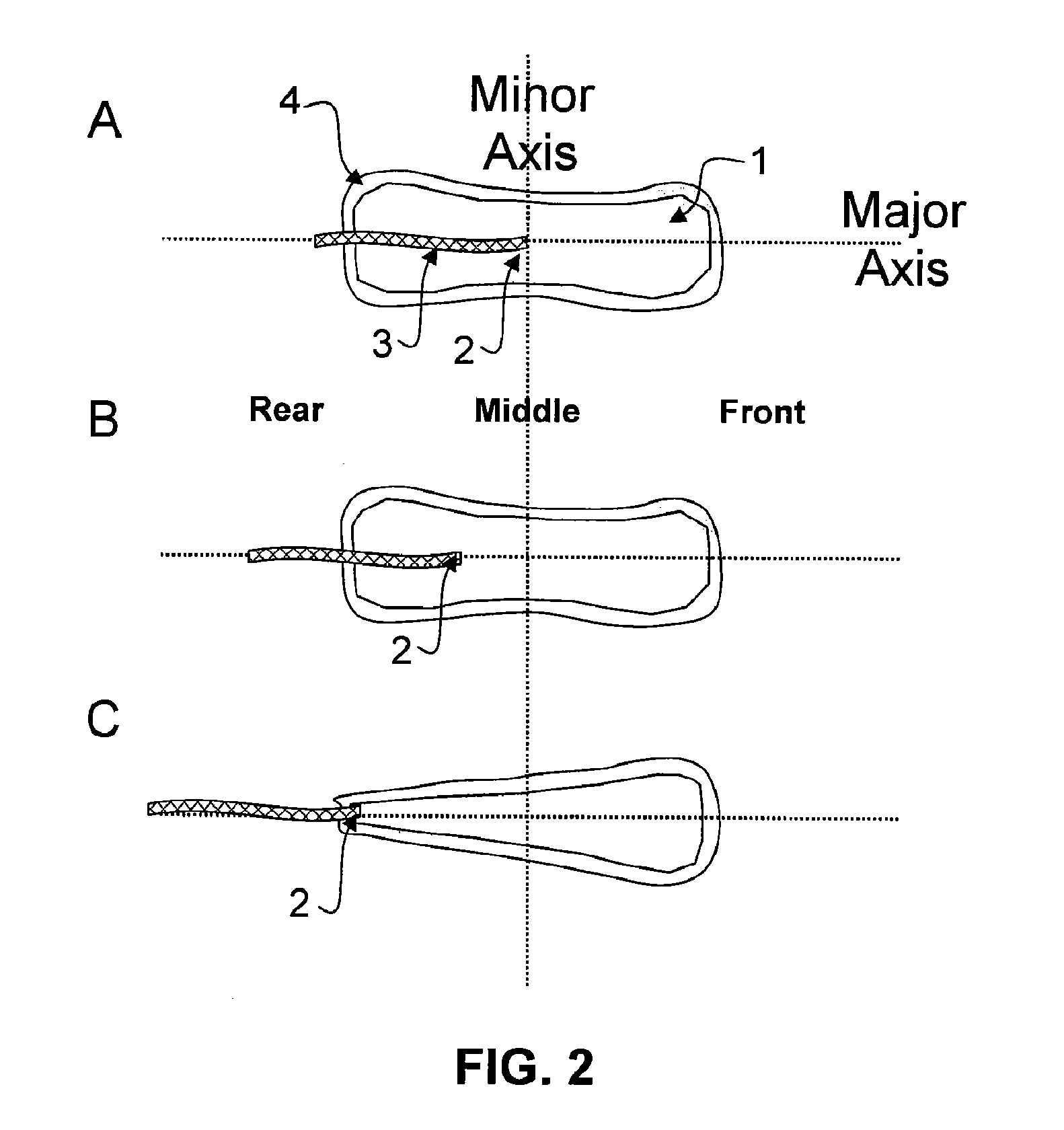

[0033]FIG. 1A shows a side view of the pad (1), illustrating the braid (3) attached to the pad (2) roughly in the center of the elongated pad. FIG. 1B-D demonstrate attachment to the inner liner (6), the absorbent core (7) and the outer liner (8). FIG. 2A shows a top view of the inner side of the pad with the braid (3) attached in the middle of the pad (2). FIG. 2B shows the braid attached in the rear portion of the pad. FIG. 2C shows a braid attached to the end of a “thong” shaped pad. FIG. 3 shows a perspective view.

example 2

Pad Manufacture

[0034]In one embodiment, the pad of the invention is manufactured using a sanitary napkin pad, and incontinence pad machine. Production can easily run a wide range of raw materials and produce sanitary napkins with various manufacturing structures because the machine has been designed to assure simple and rapid size changes. In one embodiment, ultrathin cores with binders provide a number of fluff layers with an integrated SAP powder layered with non-woven airlaid transition layers. Braided attachments are incorporated with adhesive on the topsheet prior to folding, stacking and packing Thong pantyliners with a 180 degree turn are woven directly into the braided string. After the braid is incorporated, the napkins enter a tri-folding, stacking and packing unit, which completes the production process.

example 3

Ultrasonic Sealing

[0035]The braided attachment can be added after the sanitary napkin or incontinence pad is assembled. In one embodiment, a braid with three threads made of cotton and lined with a man-made absorbent material are sewn or sealed by ultrasound to the inner liner of the absorbent pad. The cotton braid is pressed using a press at 7000 kg for 15 minutes. The braid is placed in the middle of the sanitary napkin. In one embodiment using a 24-cm sanitary napkin the braid is placed at 12 cm. The braid was fixed to the sanitary napkin using ultrasound. Briefly, the braid is unwound at one end to create “roots” about 2 cm long inside the sanitary napkin through the inner liner and into the absorbent pad. The un-braided “roots” are heated by ultrasound and adhered to the inner liner leaving the “roots” embedded in the absorbent pad. In one embodiment the braid is 12 cm long. In a preferred embodiment the braid is 15 cm long. A loose braid can be used to keep the material soft a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com