Heat exchanger and turbulator for the same

a technology of heat exchanger and turbulator, which is applied in the direction of heat transfer modification, lighting and heating apparatus, laminated elements, etc., can solve the problems of fluid turbulence performance degradation, and achieve the effect of reducing fluid flow resistance and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

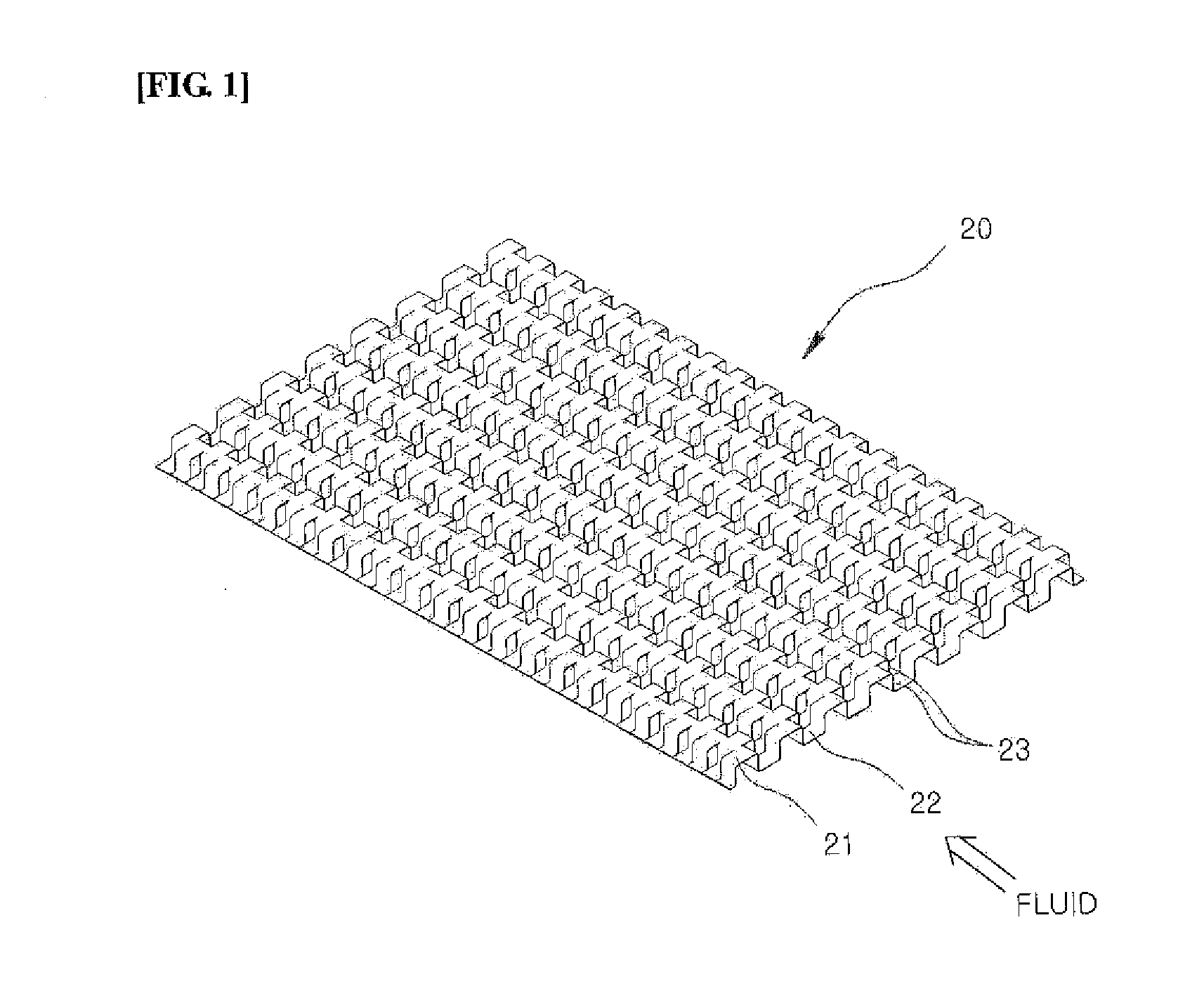

[0039]Hereinafter, a heat exchanger and a turbulator for the heat exchanger according to an exemplary embodiment of the present invention will be described with reference to FIGS. 2 to 14.

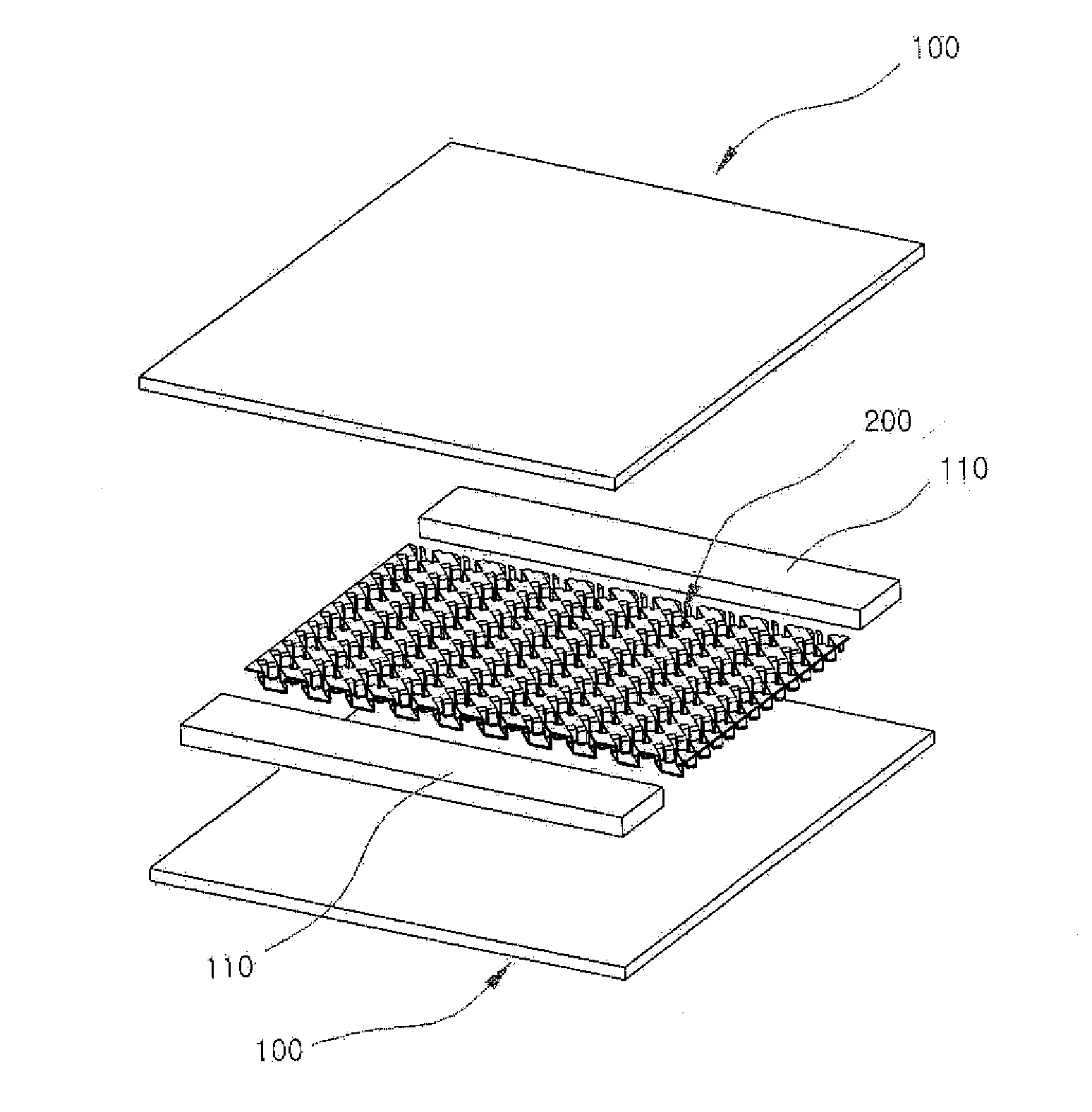

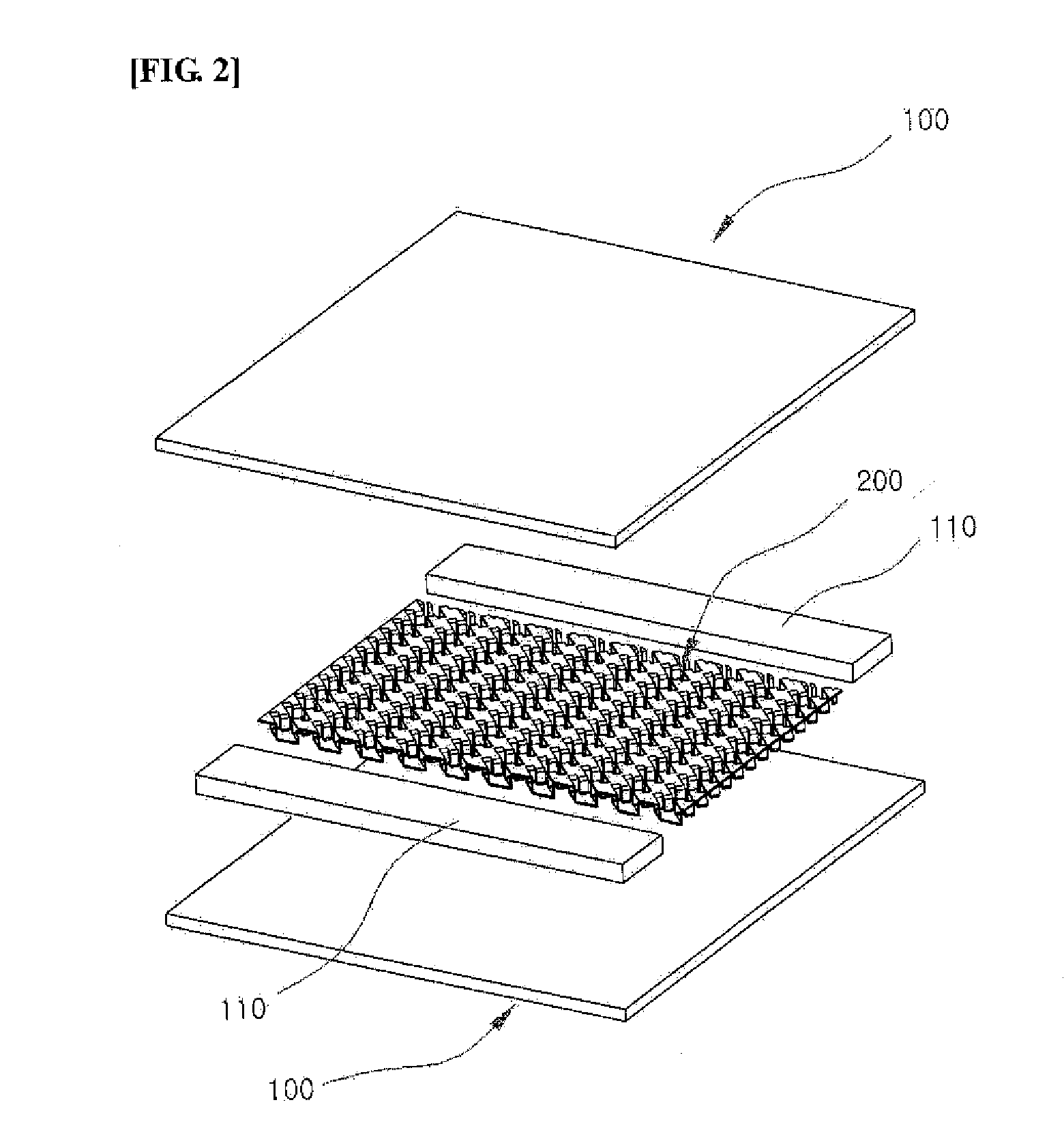

[0040]The heat exchanger according to the exemplary embodiment of the present invention includes a heat exchange plate 100 and a turbulator 200 as shown in FIG. 2.

[0041]The heat exchange plate 100 performs heat exchange with a fluid and guides the flow of the fluids. A plurality of heat exchange plates 100 are provided, and stacked on each other while being spaced apart from each other.

[0042]In addition, partition bars 110 are interposed between the heat exchange plates 100 corresponding to both side ends of the heat exchange plates 100 when viewed in the flow direction of a fluid, thereby uniformly maintaining the distance between the heat exchange plates 100 while defining the fluid passage.

[0043]In this case, two or three partition bars 110 may be provided according to the number of the fluid pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com