Drywell retrofit sump insert for storm water treatment

a technology for storm water treatment and sump inserts, which is applied in the direction of sewage draining, separation processes, agriculture, etc., can solve the problems of affecting the function of drywells, affecting the service life of drywells, and unable to convey storm water from developed properties to municipal storm sewer systems, etc., to achieve the effect of convenient placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

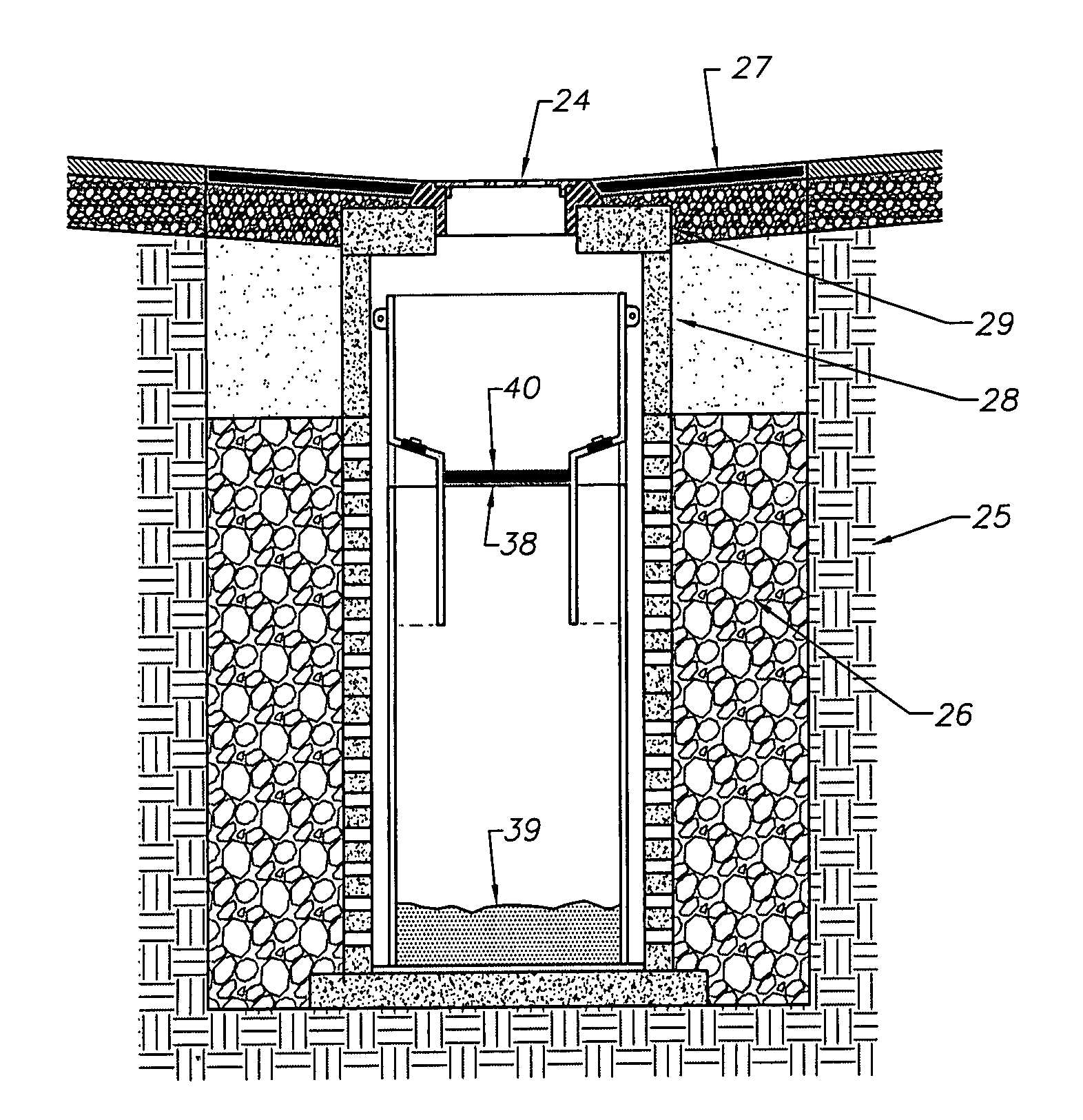

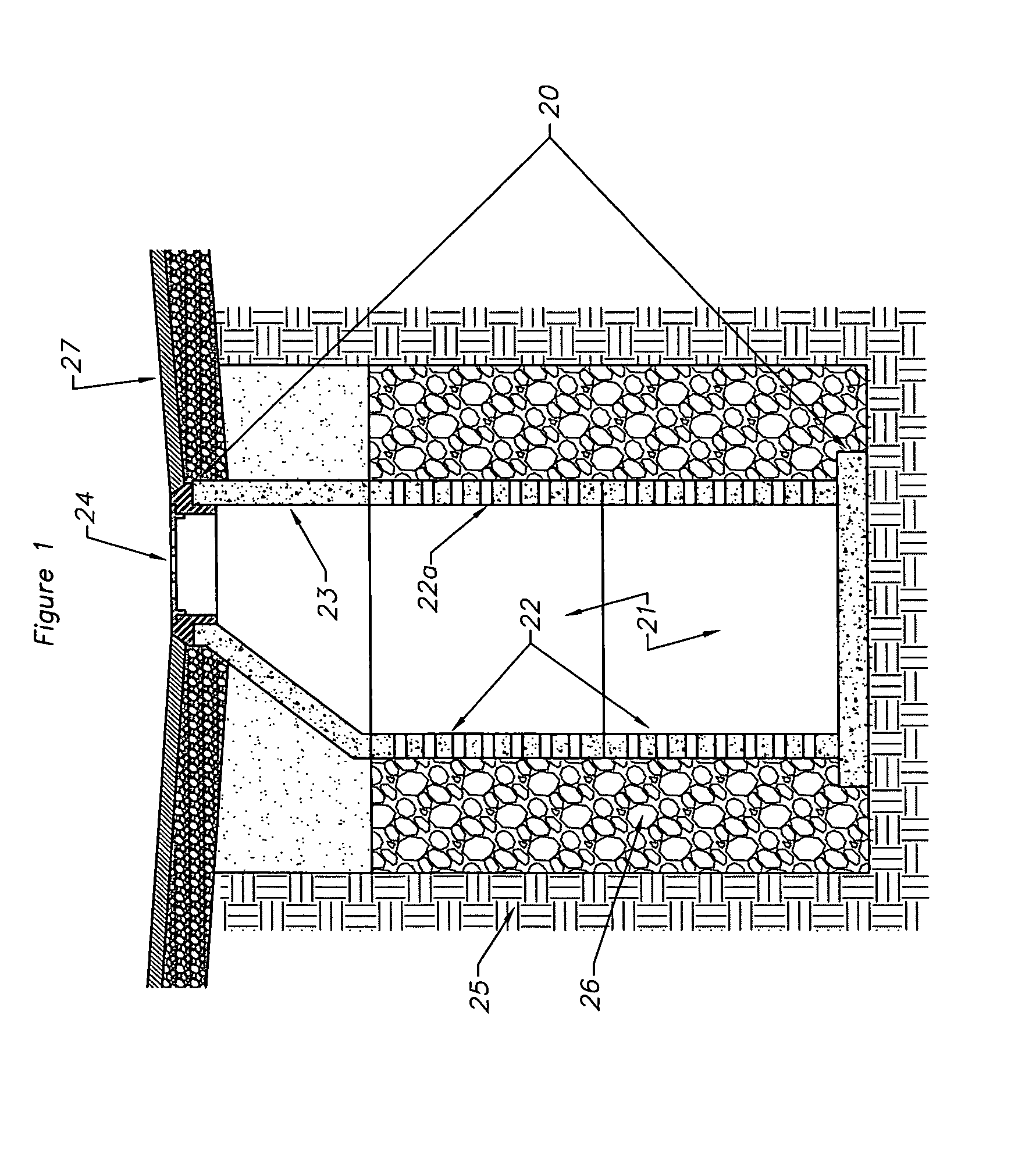

[0017]Referring more particularly to the drawings, FIG. 1 shows a typical drywell 20 of the type to which this invention could be applied. The drywell chamber 21 is constructed of a pair of stacked perforated precast concrete cylinders 22 topped with a precast concrete cone 23 and a grated steel lid 24. The precast concrete components have been placed in a hole excavated into the native soils 25 and backfilled with drain rock 26. The adjacent paved surfaces 27 are typically constructed such that they are sloped causing storm water to run toward or drain directly into the drywell 20 through the grated steel lid 24. Once storm water is collected into the drywell chamber 21 the water is discharged through the perforations 22a of the precast concrete cylinders 22. The storm water is then infiltrated through the drain rock 26 and into the native soils 25.

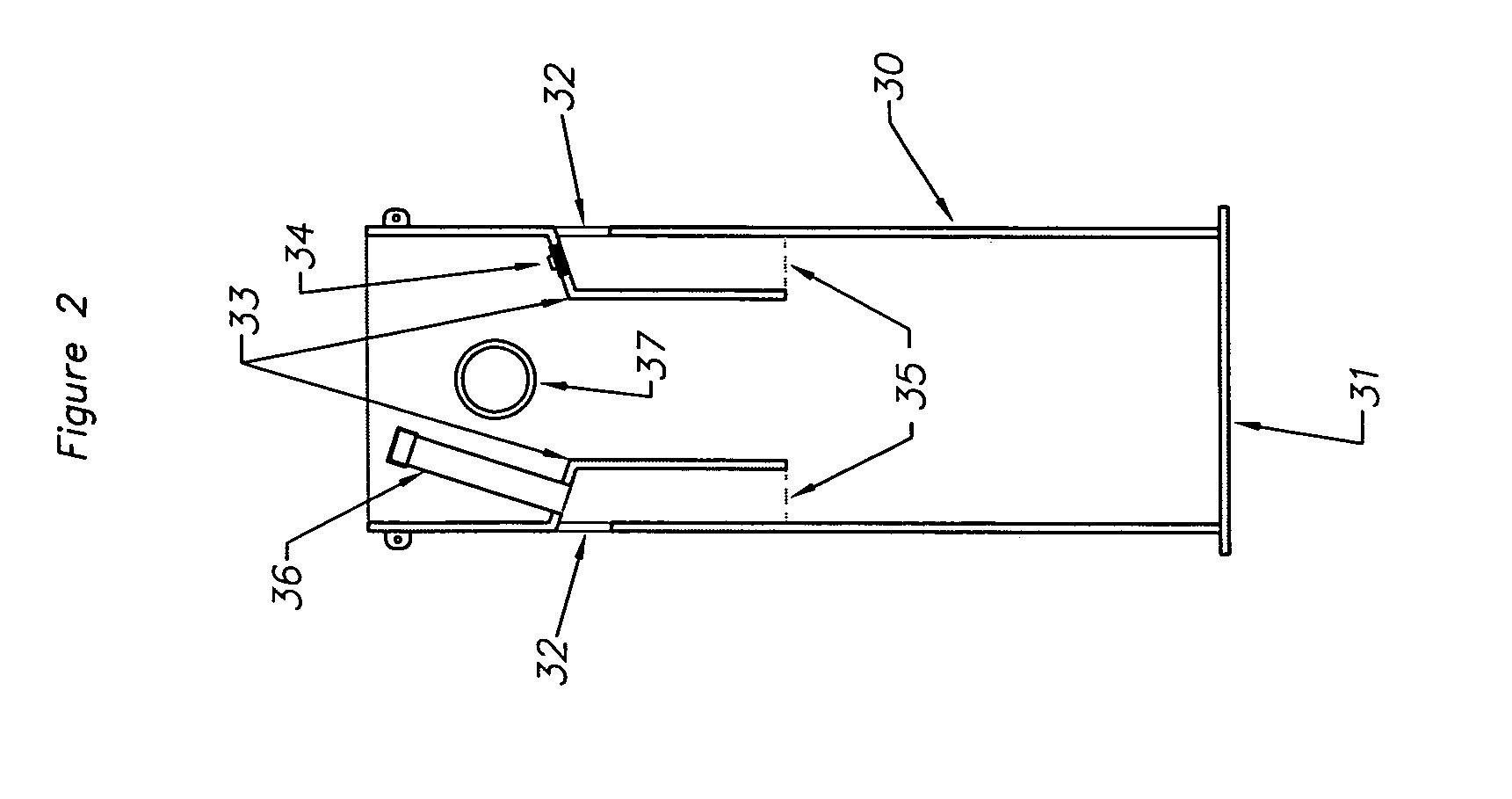

[0018]This particular invention is directed toward retrofitting previously constructed drywells of the type described above in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com