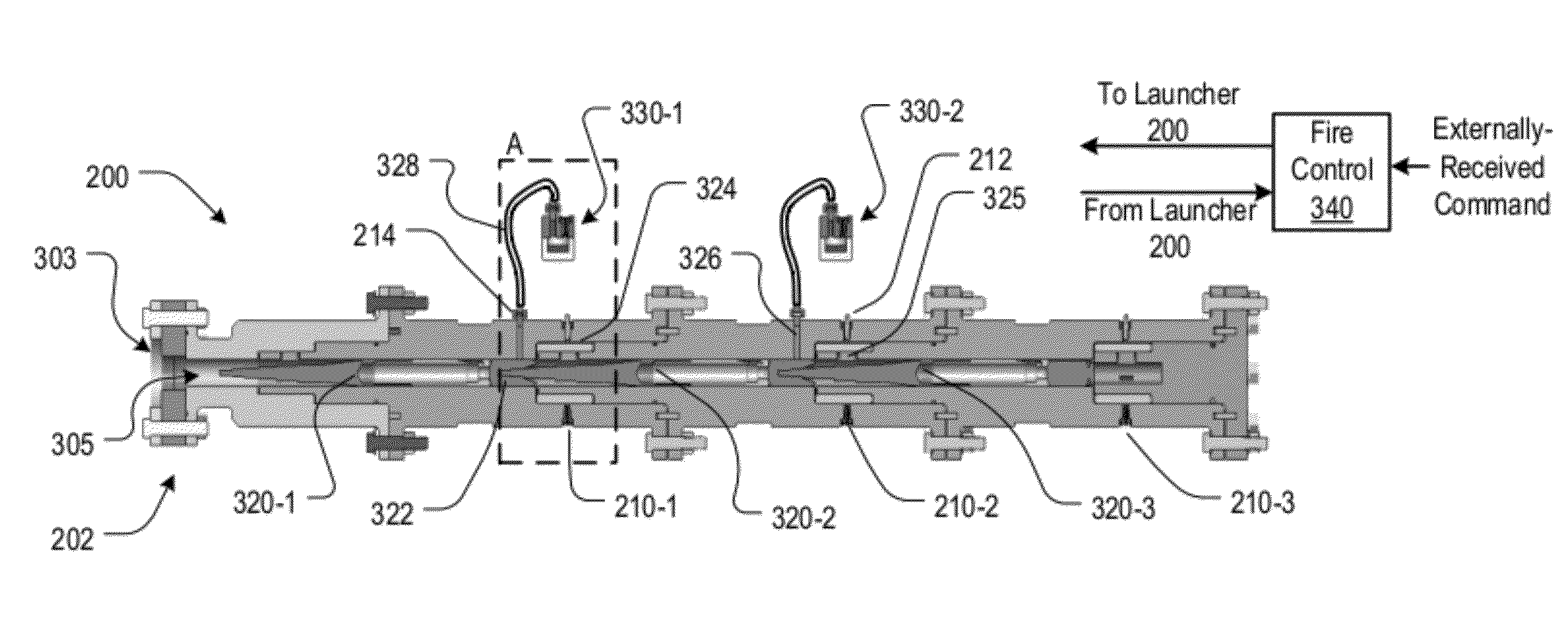

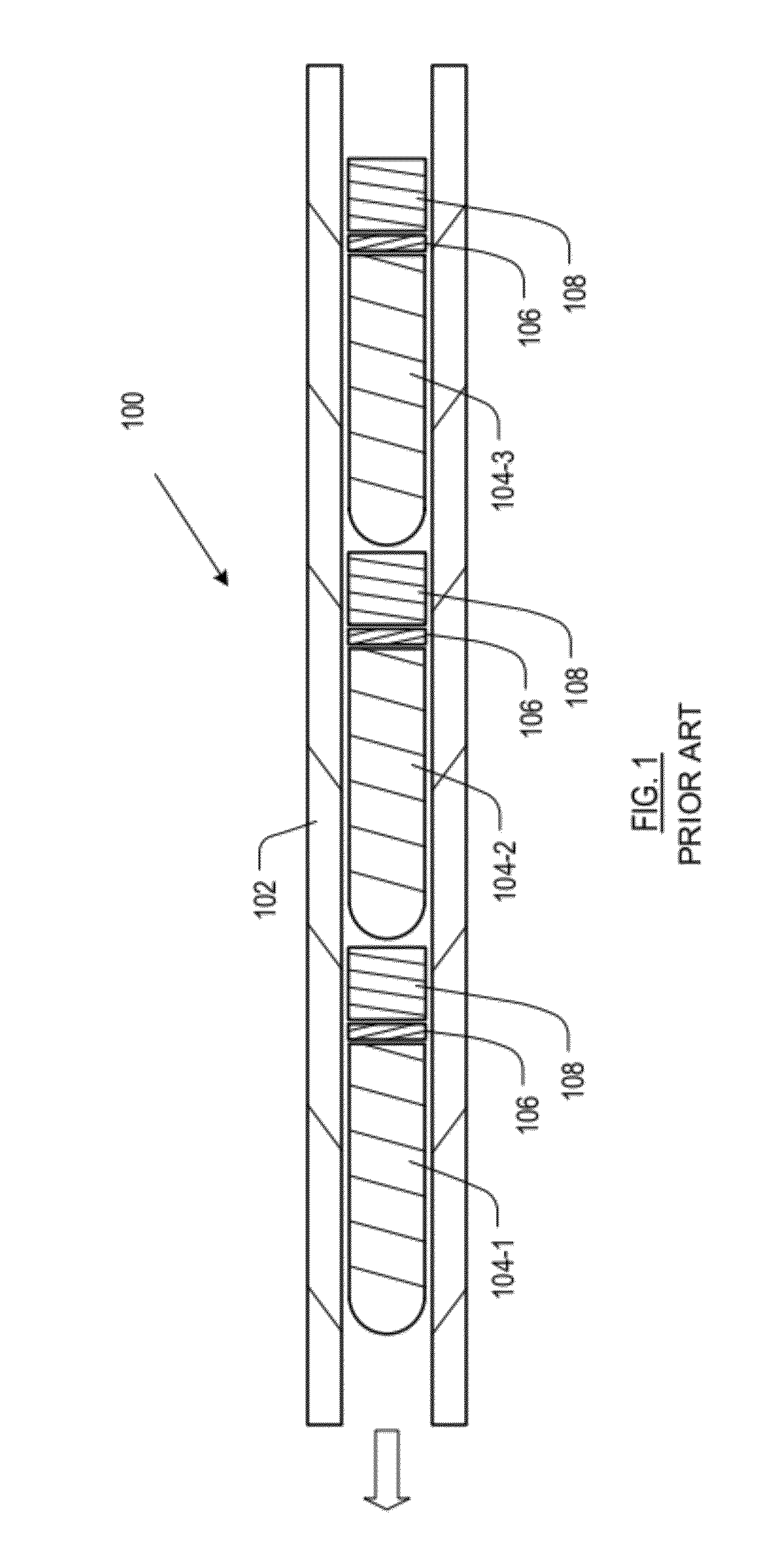

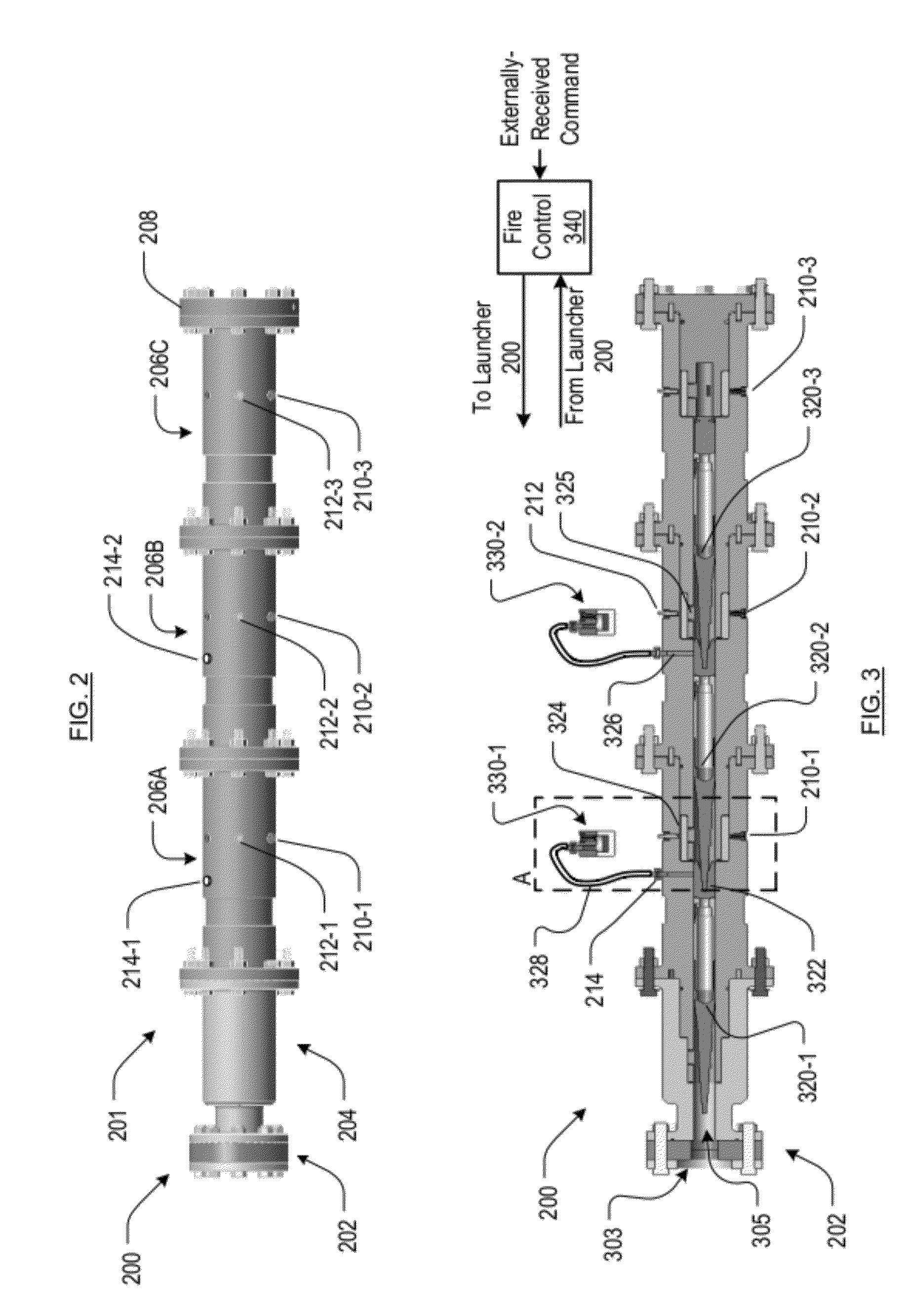

Multi-shot Launcher Comprising External Propellant

a propellant and multi-shot technology, applied in the field of multi-shot launchers comprising external propellant, can solve the problems of high muzzle velocity of guns, inability to fire when water is in the barrel, and difficulty in supercavitation rounds, etc., and achieve the effect of high velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The terms appearing below are defined for use in this disclosure and the appended claims as follows:[0038]“Operatively Coupled” means that a first object, which might be remote from a second object, can have some effect on the second object or have some effect on a third object through the second object, etc. For example, consider a rigid linkage having a first end and a second end. The first end attaches to a plate and the second end abuts a wall. The linkage is capable of transferring, to the wall, a force that is received at the plate. The linkage and the plate can therefore be considered to be operatively coupled for transmitting a force. Operatively-coupled objects need not be in direct contact with one another and, as appropriate, can be coupled through any medium (e.g., semiconductor, air, vacuum, water, copper, optical fiber, etc.). The coupling between operatively-coupled objects can transmit, as appropriate for the nature of the coupling and the objects, any type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com