Apparatus and method for thawing a product

a technology of apparatus and products, applied in the field of apparatus and methods for thawing a frozen commodity, can solve the problems of discoloration of food products, determining which food products are properly thawed, and growth of bacteria in food products that may be transmitted to contaminate adjacent food products and other areas of the warehous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

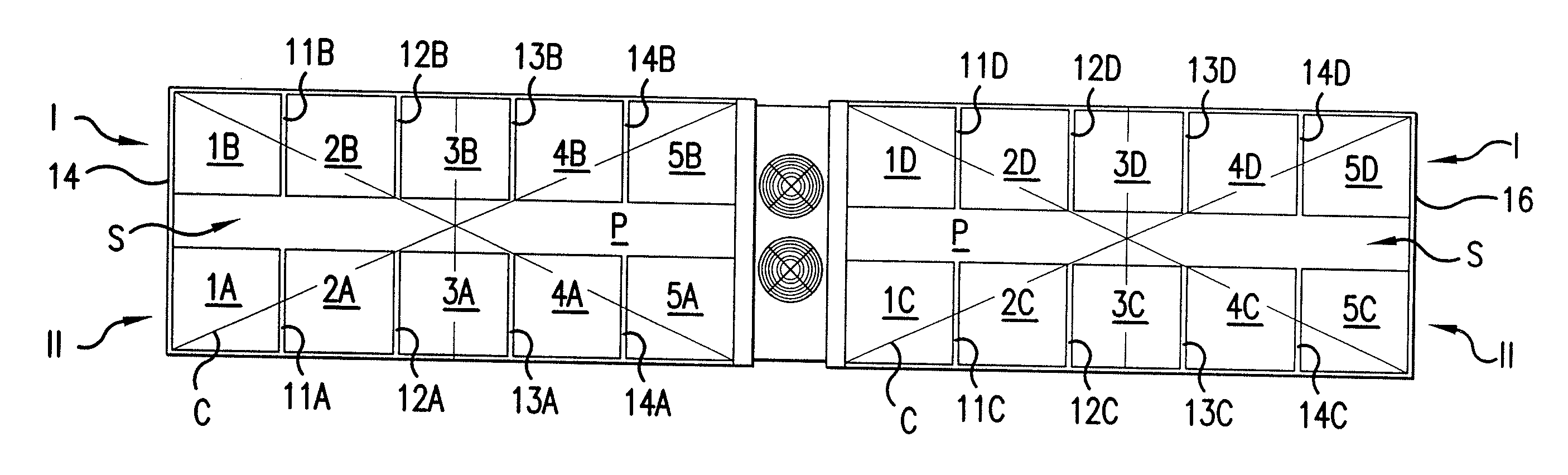

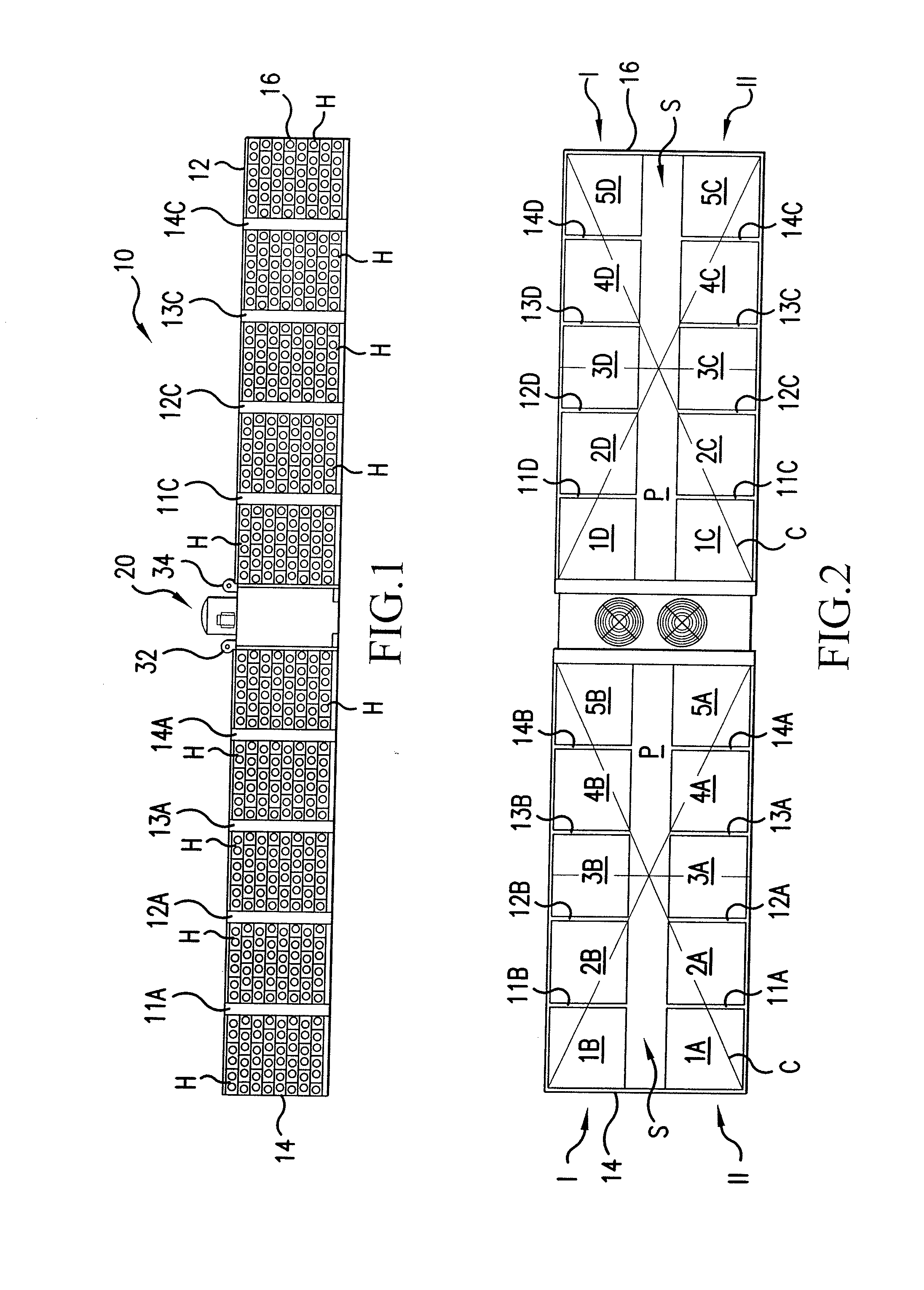

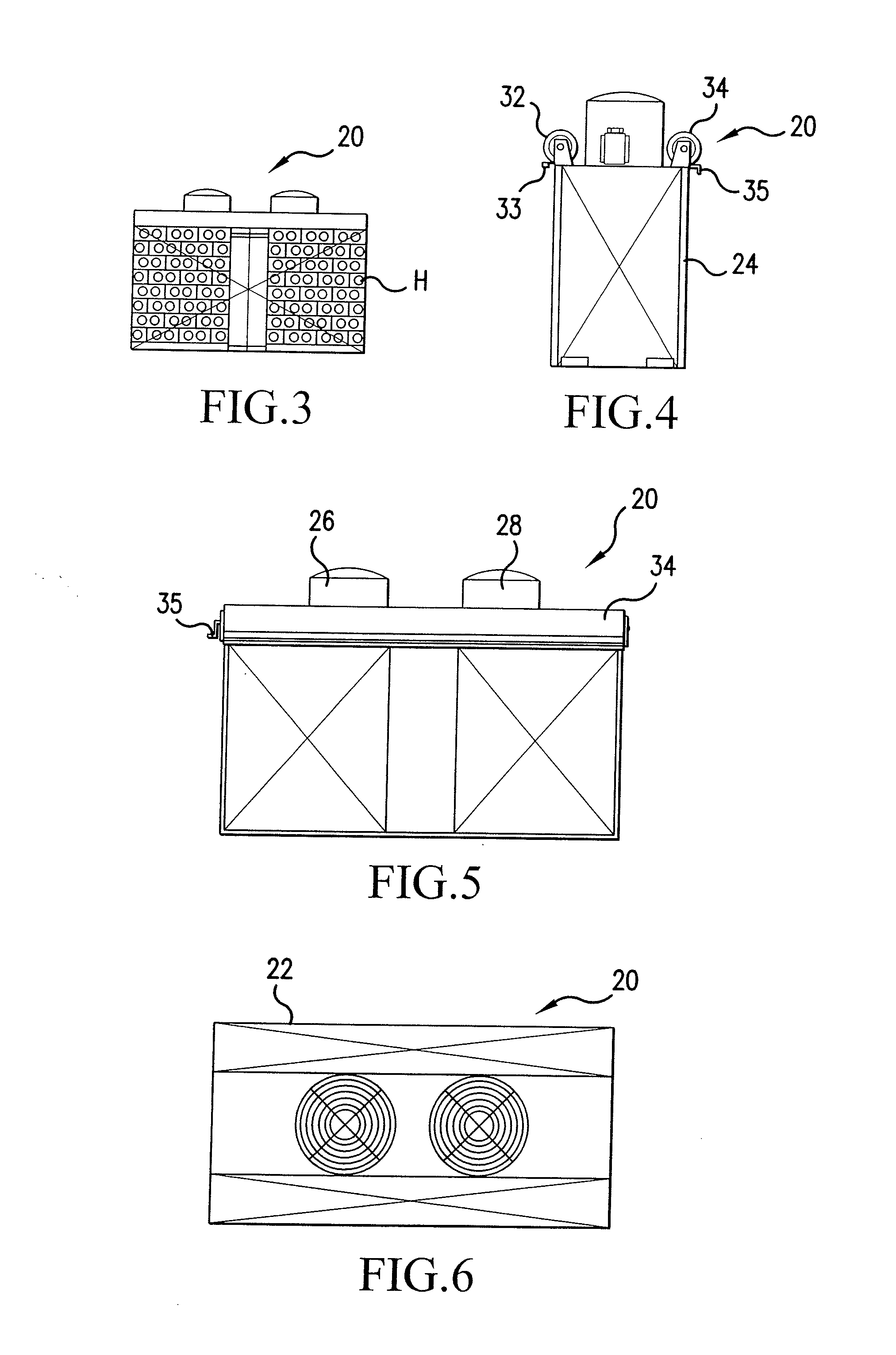

[0038]As illustrated in FIGS. 1-3, an apparatus 10 is provided for thawing a commodity, such as thawing a food product. A plurality of pallets 1A-5A, 1B-5B, 1C-5C and 1D-5D are provided with the commodity stacked on the pallets and the pallets arranged in two rows I and II with a space S formed therebetween. The term space means that the pallets are substantially equally disposed relative to each other to form a continuous space between the pallets. In addition, the term space means that the pallets may be arranged at an angle with corners of the end pallets engaging each other and the space continuing to enlarge from the end pallets to an air handler 20.

[0039]A cover C is positioned to be placed on the space S to seal the two rows of pallets along the top space S. In addition, the cover C may be positioned on at least on a portion of the top surface 12 of the commodities for sealing the two rows of pallets along the top surface to form the plenum. In addition, the cover C may also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com