Aseptic packaging installation having aseptic buffer zones

a technology of aseptic packaging and buffer zones, which is applied in the direction of packaging machines, bottle-handling machines, bottle operations, etc., can solve the problems of complex installation, difficult implementation of dynamic sealing, and high production, maintenance and upkeep costs, so as to reduce pollution risk and simplify production and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

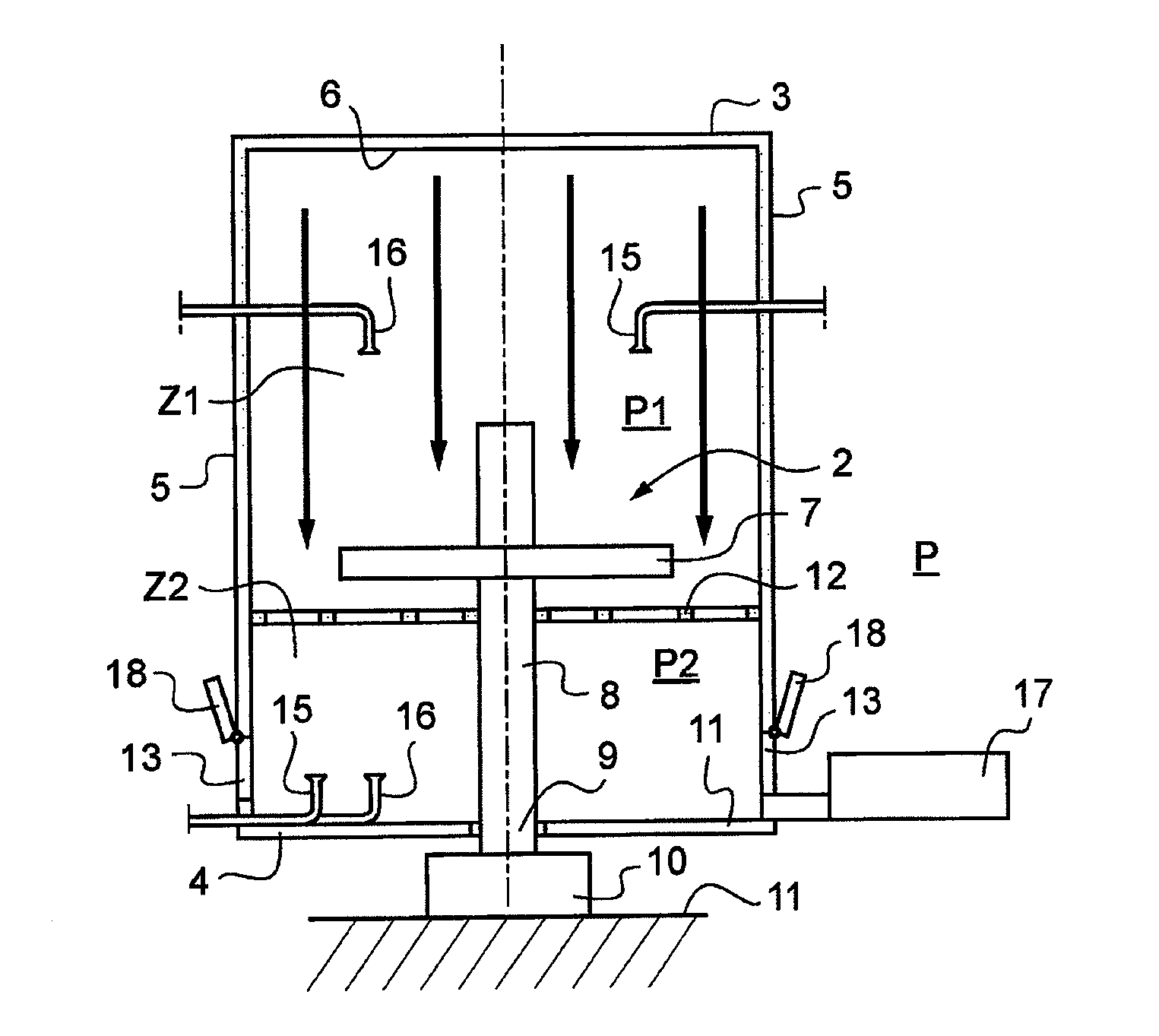

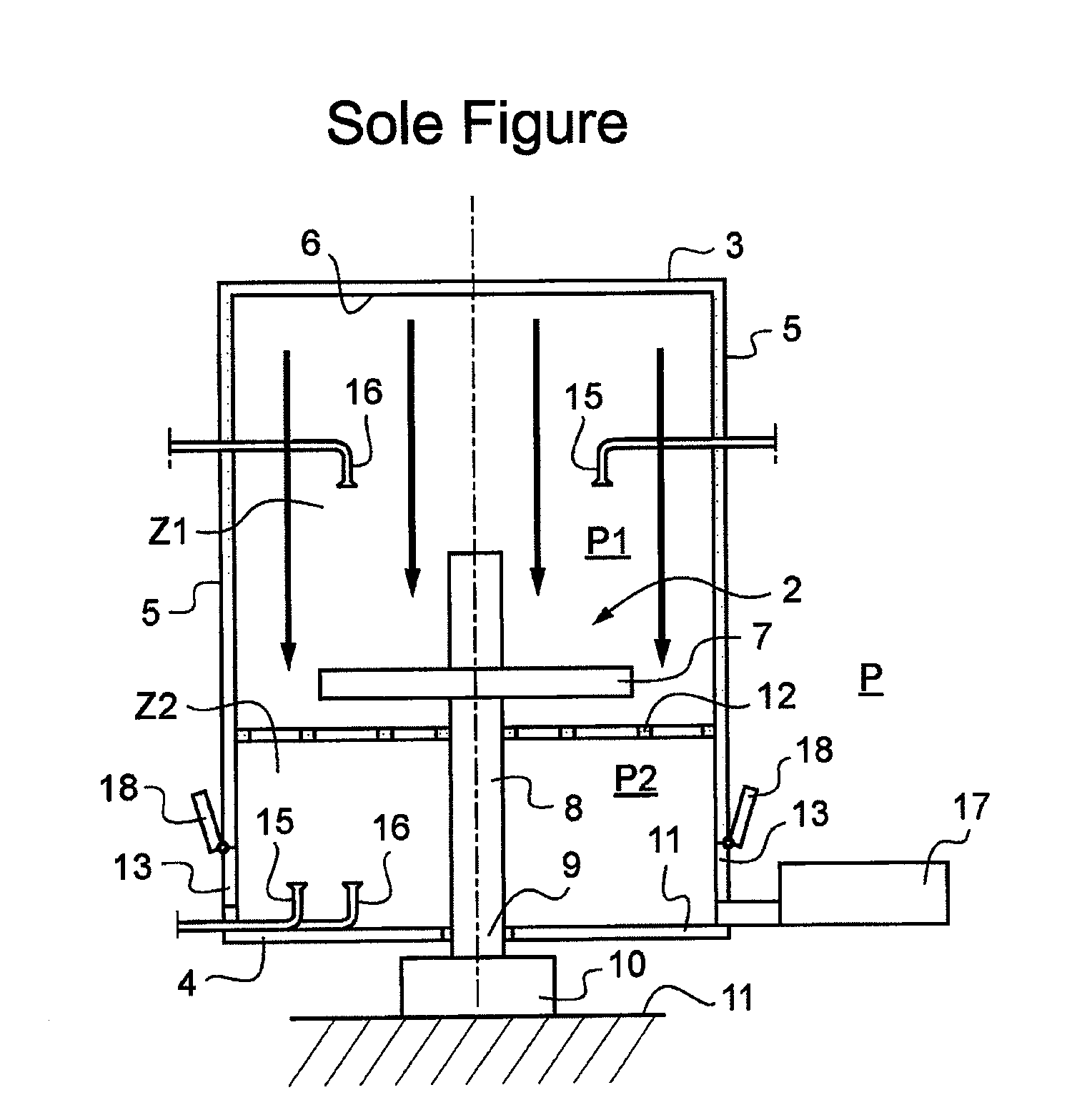

[0015]With reference to the figure, the aseptic packaging installation shown is designed for packaging a substance in containers (not shown). The installation includes a stand 1 carrying a line of machines 2 (only one of which is shown in the figure), such as filler machines, cap heat-sealing machines, and stopper insertion machines, and an enclosure 3 surrounding the machines and comprising a floor 4, walls 5, and a ceiling 6.

[0016]Each machine 2 includes a platform 7, provided with container treatment means, which is constrained to rotate with a column 8 mounted to rotate on the stand 1. A stationary table 11 extends under the platform 7 in a position that is spaced apart therefrom and that has the column 8 passing therethrough. Under the table 11, the column 8 has a portion 9 for connection to rotary drive means 10.

[0017]The platform 7 of each machine 2 extends into a packaging zone Z1 that is defined inside the enclosure 3 and that is subjected to a sterile laminar stream (repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com