High efficiency thermal management system

a thermal management system and high efficiency technology, applied in the field of high efficiency thermal management system, can solve the problems of inherently limited system performance and efficiency, high cost, and inability to meet the needs of large volume of air flow, so as to achieve optimum fluid flow and heat transfer, improve temperature uniformity, and improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0076]Many impingement technologies exist, but few have shown commercial promise and none have gained wide-scale commercial acceptance to date due to generally high flow rate requirements and limitations on scalability.

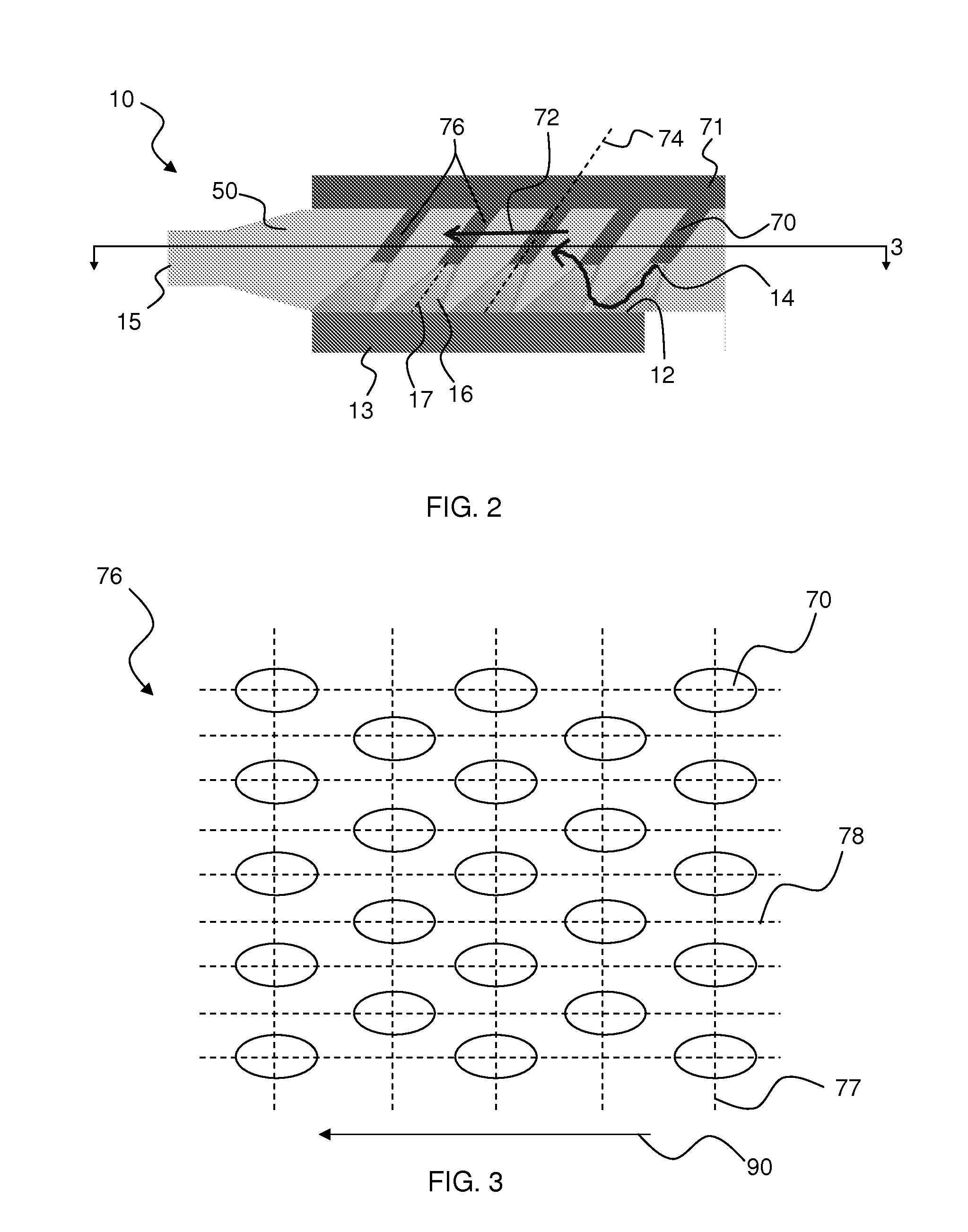

[0077]An improved impinging jet array apparatus has been developed and described herein. As described above, the current work has identified that angling the tubular nozzles and impinging the stream at a non-perpendicular angle with respect to the surface significantly improves the scalability of arrays of jets.

[0078]In addition, laboratory tests have demonstrated that two-phase impinging jets can perform 80% to 100% better than single-phase jets with the same flow rate. A chamber comprising a tubular nozzle configured to project a jet impinging on a work piece surface was configured. The pressure in the chamber was set to establish a saturation temperature of either 95° C. (FIG. 5A) or 74° C. (FIG. 5B). The latter saturation temperature (74° C.) was chosen to substan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap