Sleeve for Beverage Containers and Method of Making Same

a beverage container and sleeve technology, applied in the field of beverage containers, can solve the problems of unnecessarily large 7 mm, poor heat conduction radially outward along the thin strip of paper, and little, if any, heat being transported through the strip to the user's fingers, etc., to achieve the effect of reducing the amount of material required, and strengthening the web against stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

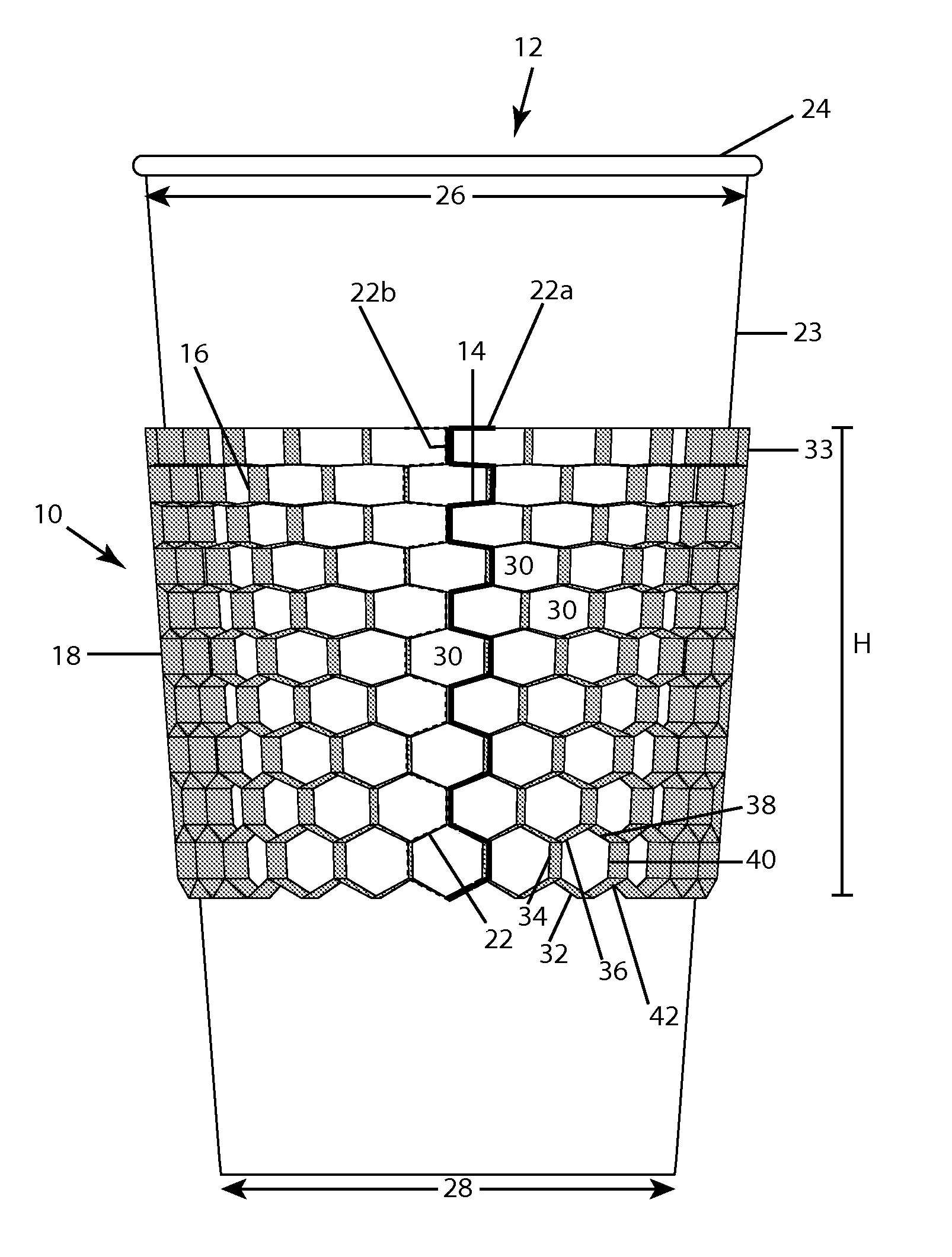

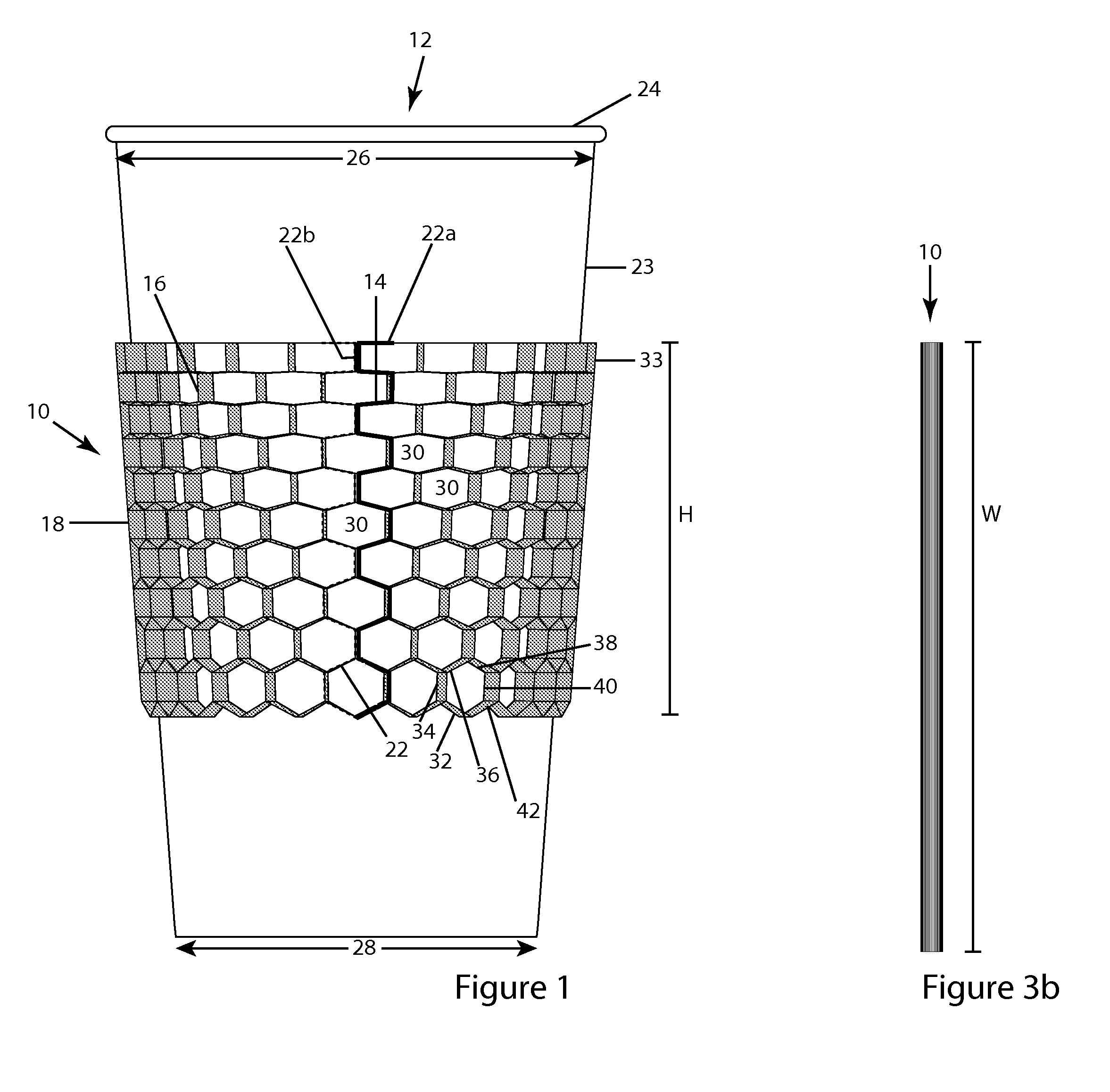

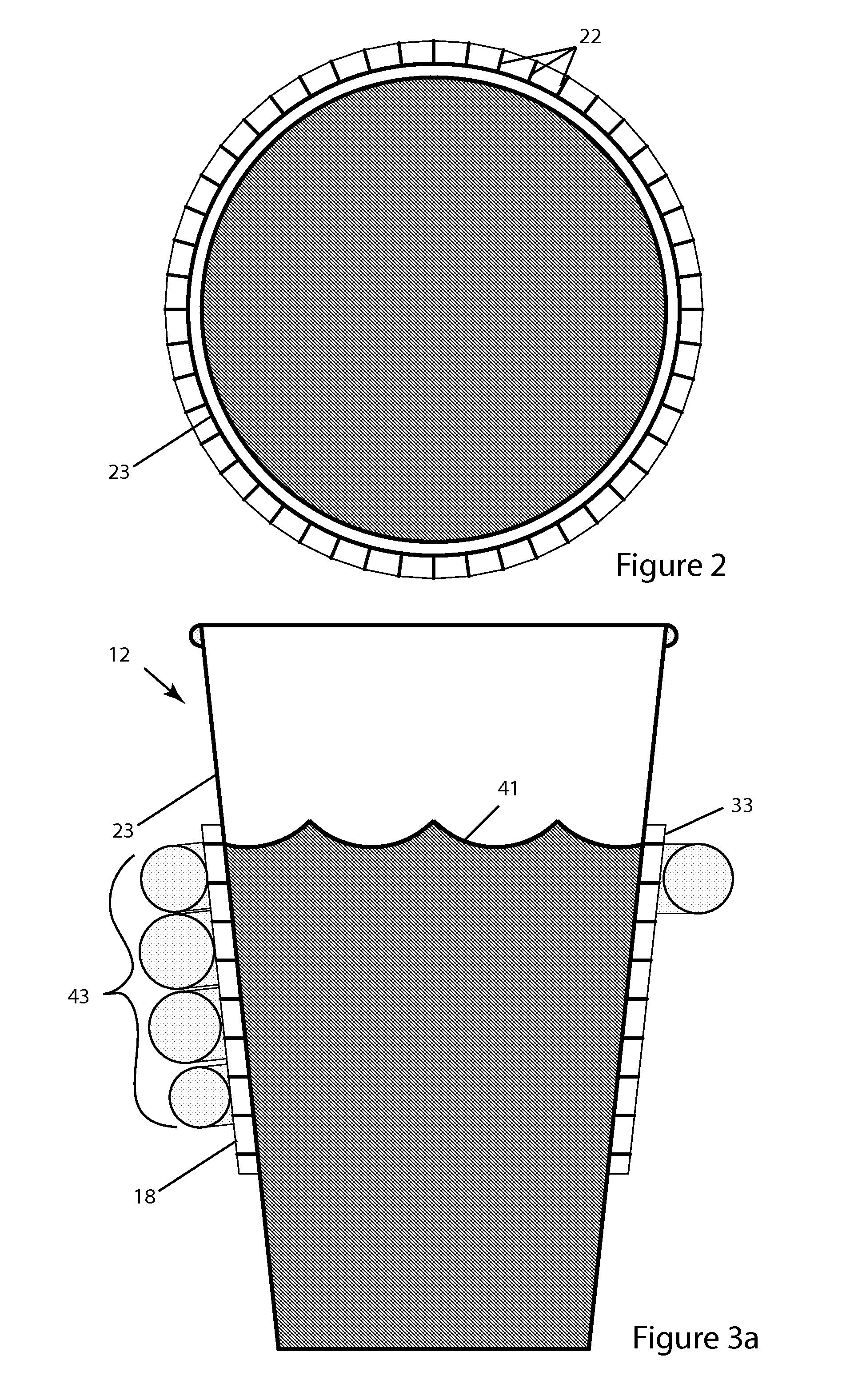

[0046]A gripping sleeve 10 for a beverage cup 12 according to a preferred embodiment of the present invention is shown in FIG. 1. As shown, the gripping sleeve 10 is comprised of an open web of material 14 which defines a tube. The web has an inner surface 16 and an outer surface 18. The inner surface conforms to the outside surface 23 of the cup 12, as explained in more detail below. The outer surface 18 defines a gripping surface.

[0047]The open web of material 14 is comprised of a series of strips of material 22 which extend generally between the inner surface 16 and the outer surface 18. As shown in FIG. 2, the strips of material 22 of the gripping sleeve 10 extend generally radially outwardly from the surface of the cup 23 when viewed from above. In this sense generally radially is intended to mean extending generally outwardly, as opposed to extending generally parallel to the outer surface of the cup, as in the prior art. In side view, the strips are oriented generally paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com