Motorised hair styling iron

a motorised, iron technology, applied in curling irons, curling tongs, hair equipments, etc., can solve the problems of variable processing results, damage to hair, and insufficient hair format, and achieve the effects of simple design, economic construction, and effective processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

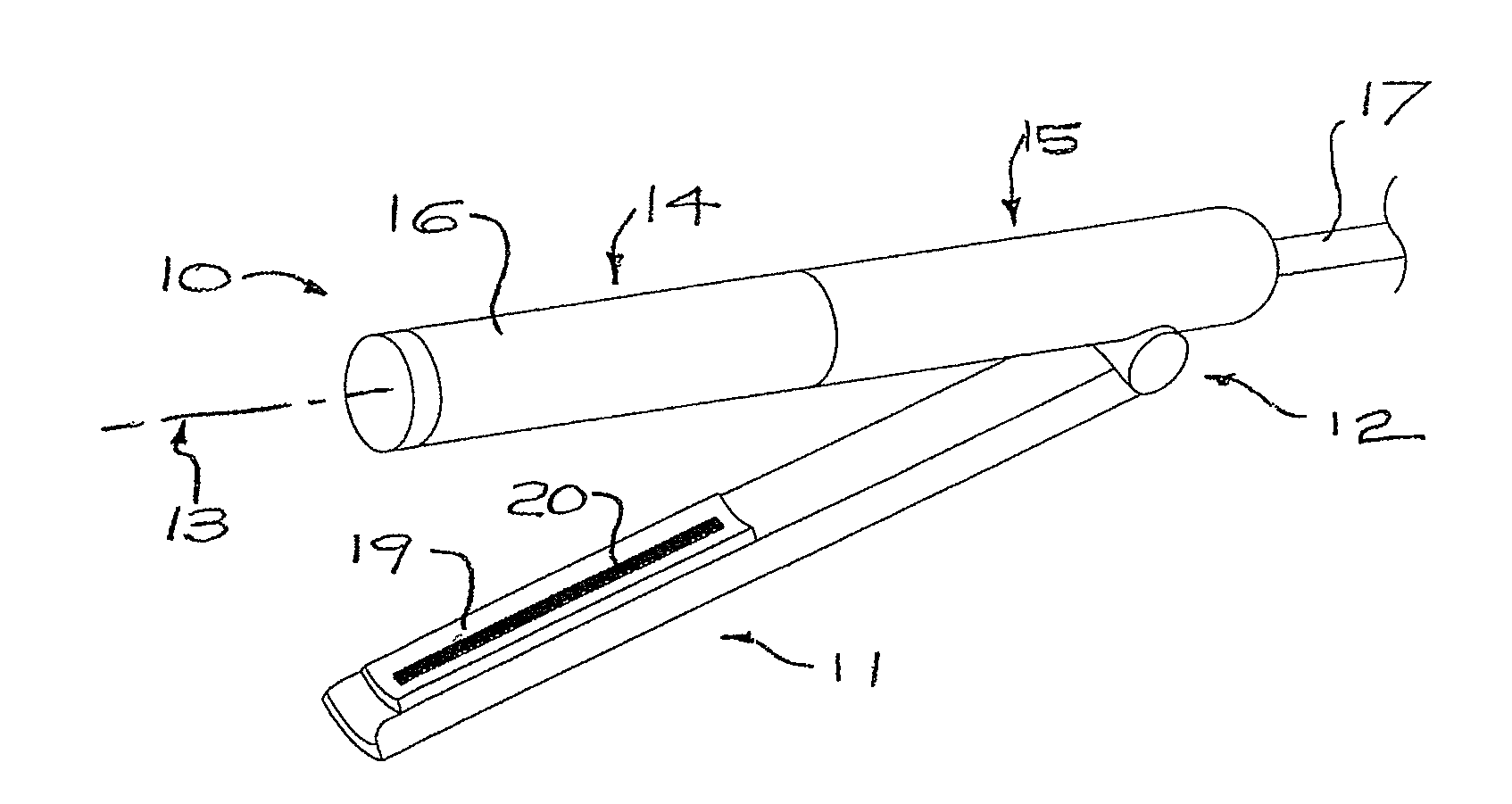

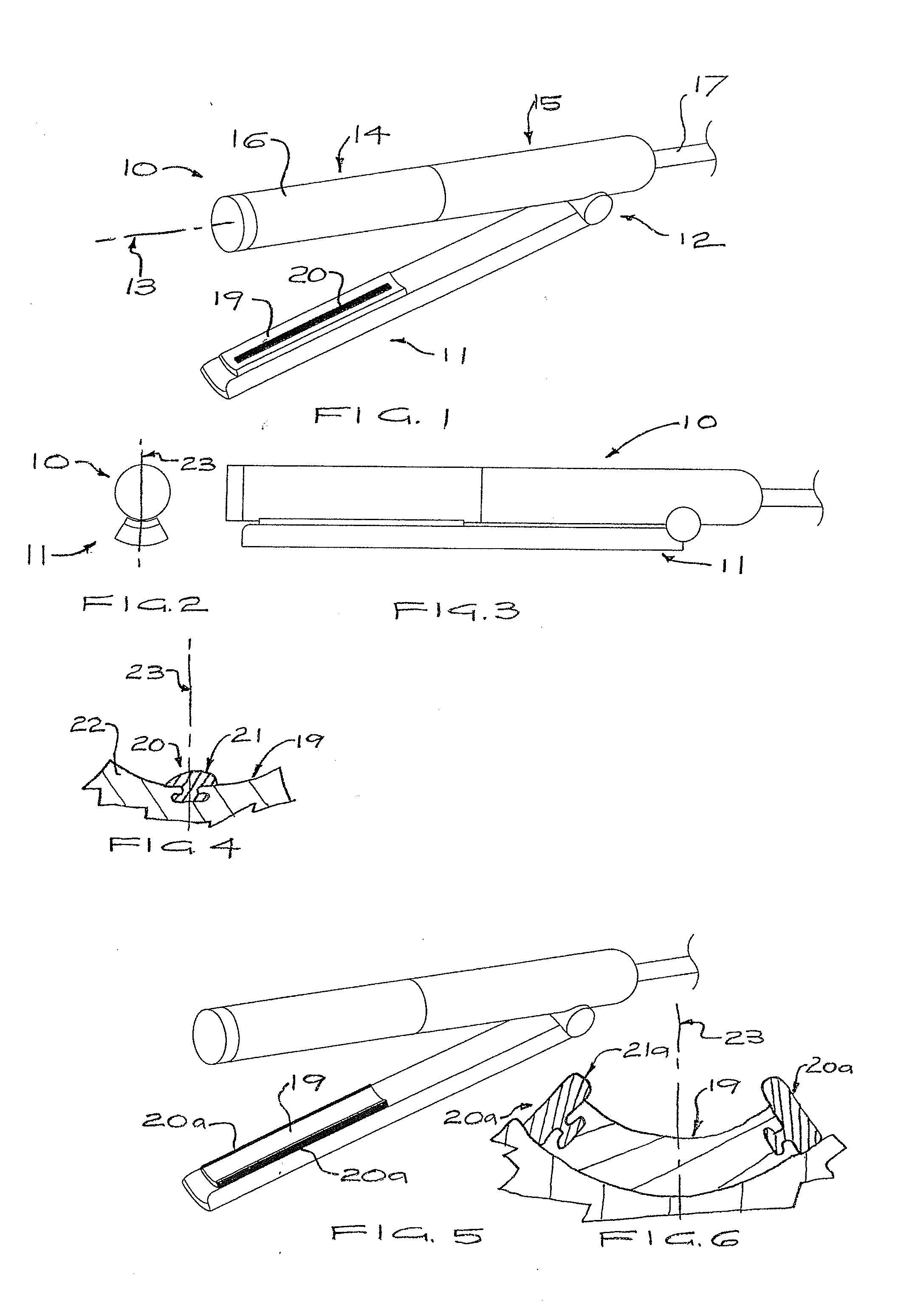

[0035]Referring to the drawings, FIG. 1 illustrates a hand held electric hair iron having first and second elongate jaws 10, 11 joined at respective proximal parts disposed near their longitudinal ends by a transverse hinge 12, shown in an open position. Both jaws 10, 11 are of hollow construction, with the first jaw 10 including a barrel 14 disposed at its outer end and a coaxial handle section 15 at its inner end. The barrel 14 has a first longitudinal axis 13 and a substantially cylindrical hair-engaging surface 16.

[0036]In the preferred embodiments illustrated, the barrel 14 is heated by an internally enclosed resistive element (not shown). Further, the barrel 14 is motor-driven to rotate about the longitudinal axis 13, or to vibrate, either generally omni-directionally or linearly or rotationally along / about an axis. Motorised hair irons having a jaw driven to rotate or vibrate are known from the prior art, and it will be understood that this can be achieved in a number of diff...

second embodiment

[0040]the second jaw is shown in FIGS. 5 and 6, in which a pair of parallel, generally coextensive, elastomeric ribs 20a are provided, each disposed adjacent opposing longitudinal edges of the hair-engaging surface 19, such that their exposed faces 21a project beyond the surface 19. The ribs 20a are disposed symmetrically on opposing sides of the central plane 23.

[0041]In preferred embodiments the width of the rib 20, 20a is between 2% and 20% of the width of the concave face 19, most preferably between 5% and 10% of the width of the face 19. Ribs 20, 20a of silicon rubber having a hardness of 40 Shore A has been found to provide good performance, but satisfactory performance can be obtained with a hardness between 30 Shore A and 50 Shore D.

[0042]In use, a lock of hair is wound in a loop about the elongate barrel 14, the user grasping the jaws to clamp the lock of hair between the faces 16, 19. In this manner the hair is pressed against the rib(s) 20, 20a while it is softened by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com