Magneto-impedance element and magneto-impedance senor including detection coil.

a magneto-impedance element and detection coil technology, applied in the direction of magnetic measurement, magnetic restrictions, instruments, etc., can solve the problems of linearity and sensitivity degradation, and achieve the effects of improving linearity, reducing power consumption, and improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

Embodiment 1

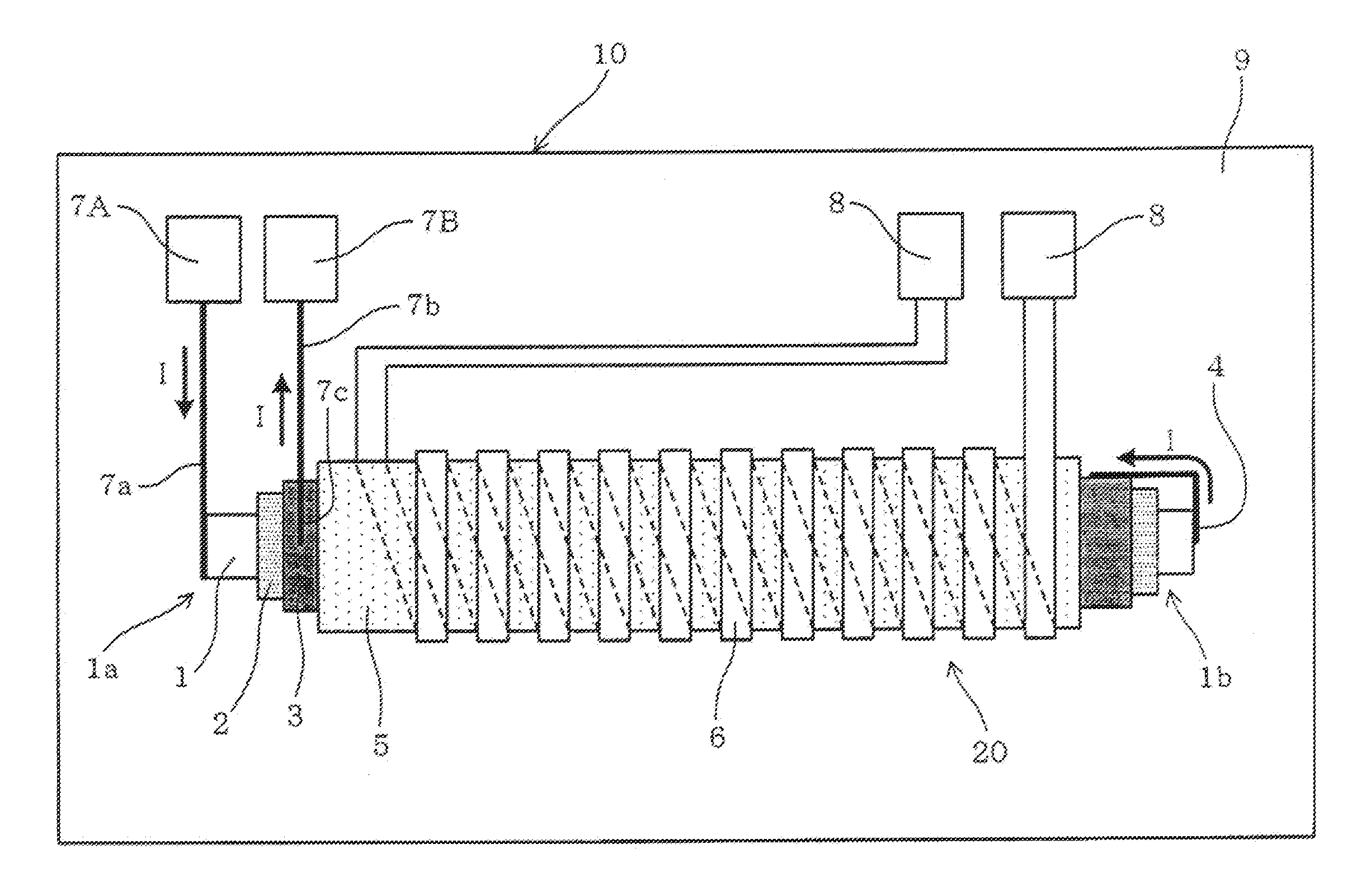

[0062]A magneto-impedance element and a magneto-impedance sensor according to an embodiment of the present invention will be described below with reference to FIGS. 1 to 9.

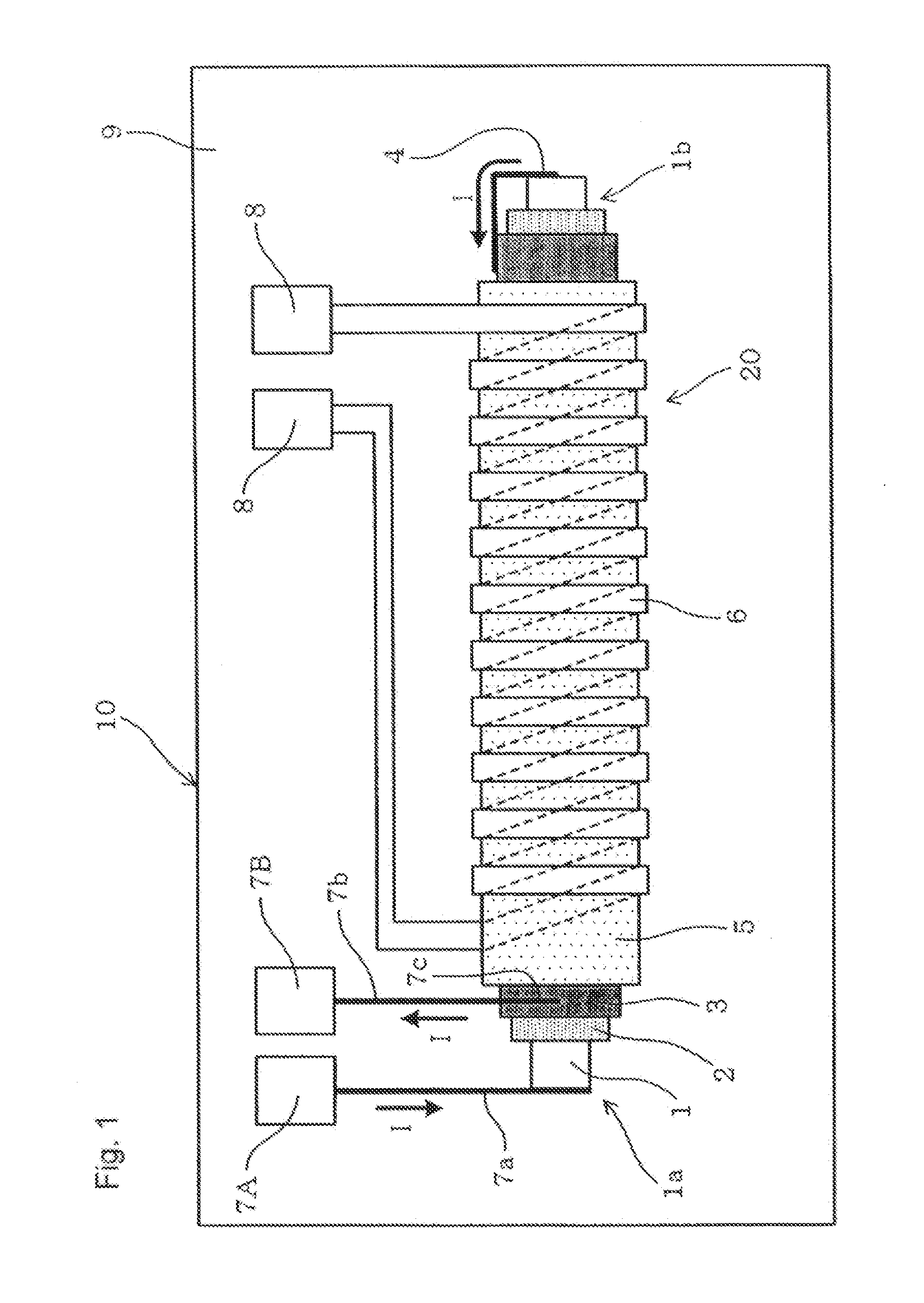

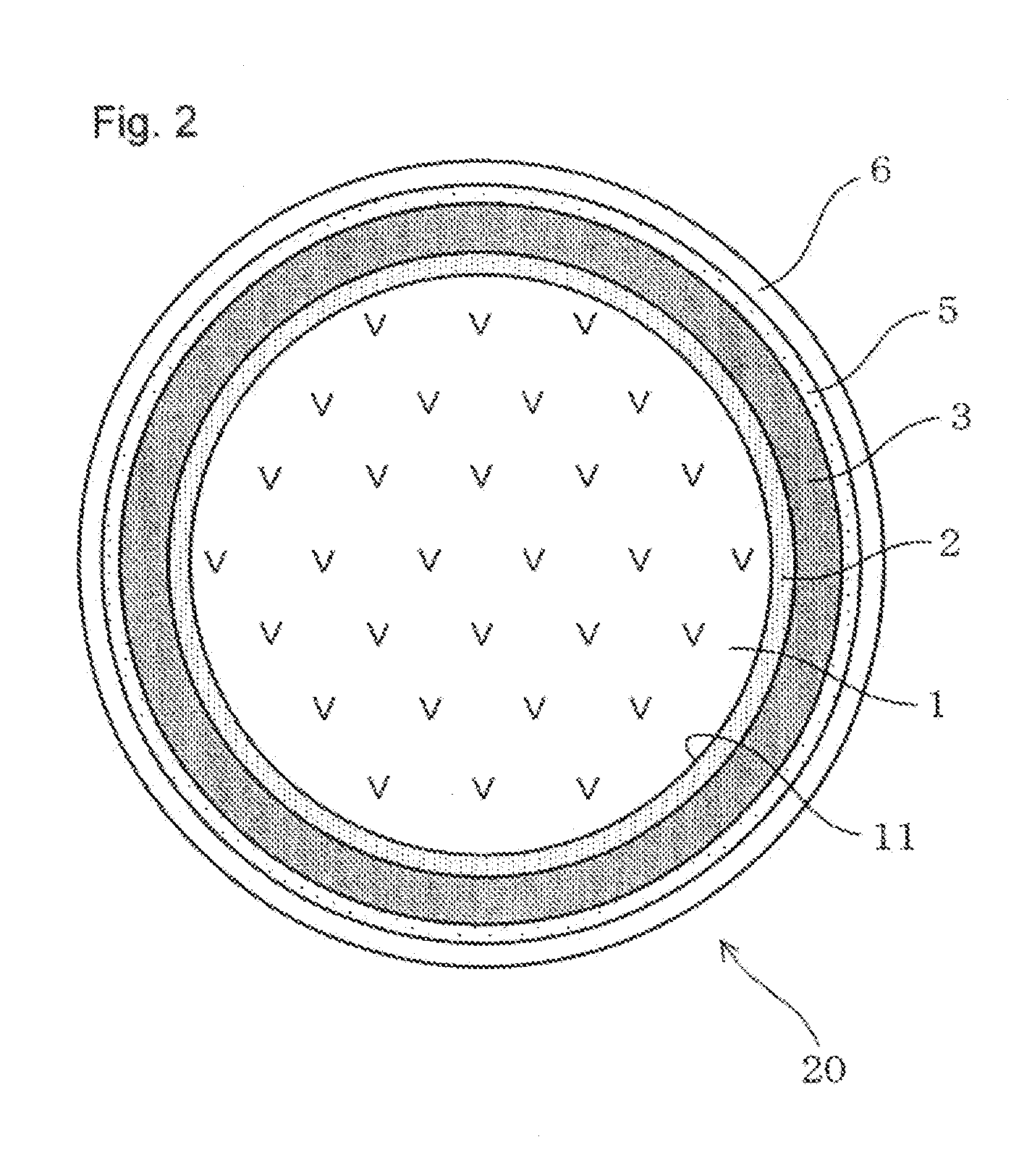

[0063]FIG. 1 is a schematic view of a magneto-impedance element 10, and FIG. 2 is a sectional view of the magneto-impedance element 10. FIG. 3 is a schematic diagram showing a flowing direction of a pulse current I.

[0064]As shown in FIG. 1, the magneto-impedance element 10 includes a magnetic sensitive member 1 having the form of a line and electromagnetic characteristics variable under the influence of a magnetic field acting from the outside, in which a pulse current I flows from one end portion 1a to the other end portion 1b in an axial direction.

[0065]A conductive layer 3 is arranged on an insulating layer 2 provided on an outer surface of the magnetic sensitive member 1.

[0066]A connection portion 4 which electrically connects the magnetic sensitive member 1 and the conductive layer 3 to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com