Method and apparatus for making cold-pilger-rolled pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

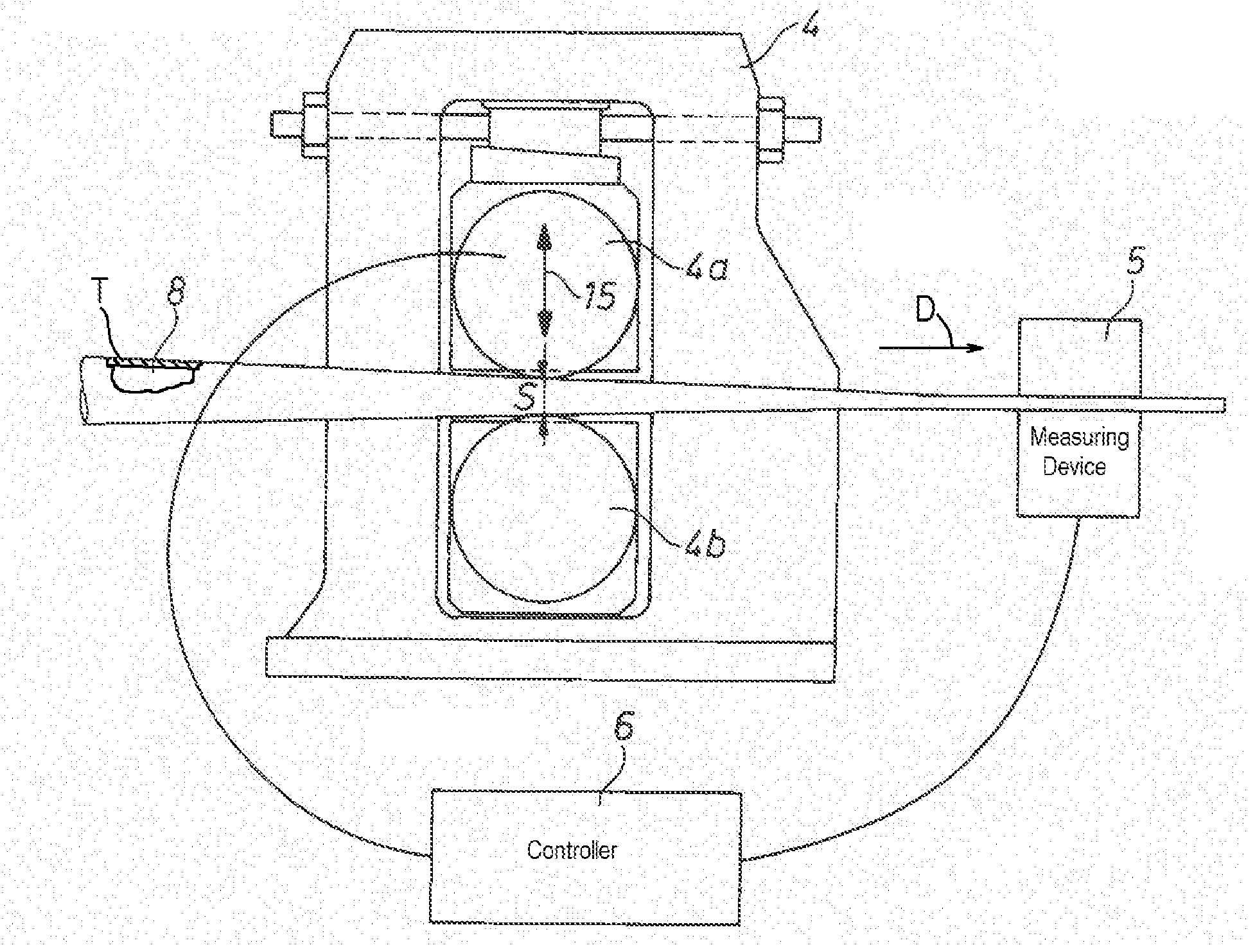

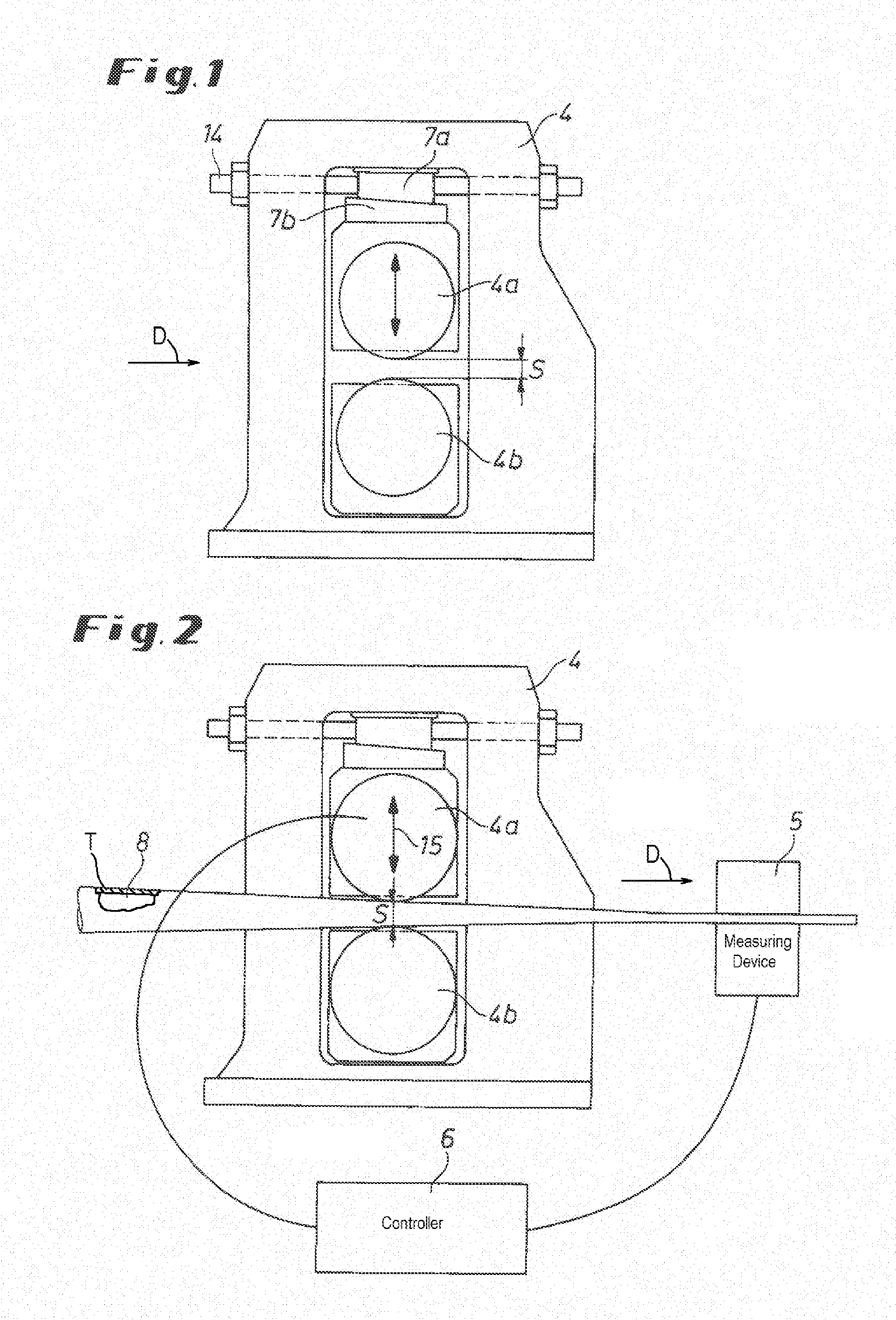

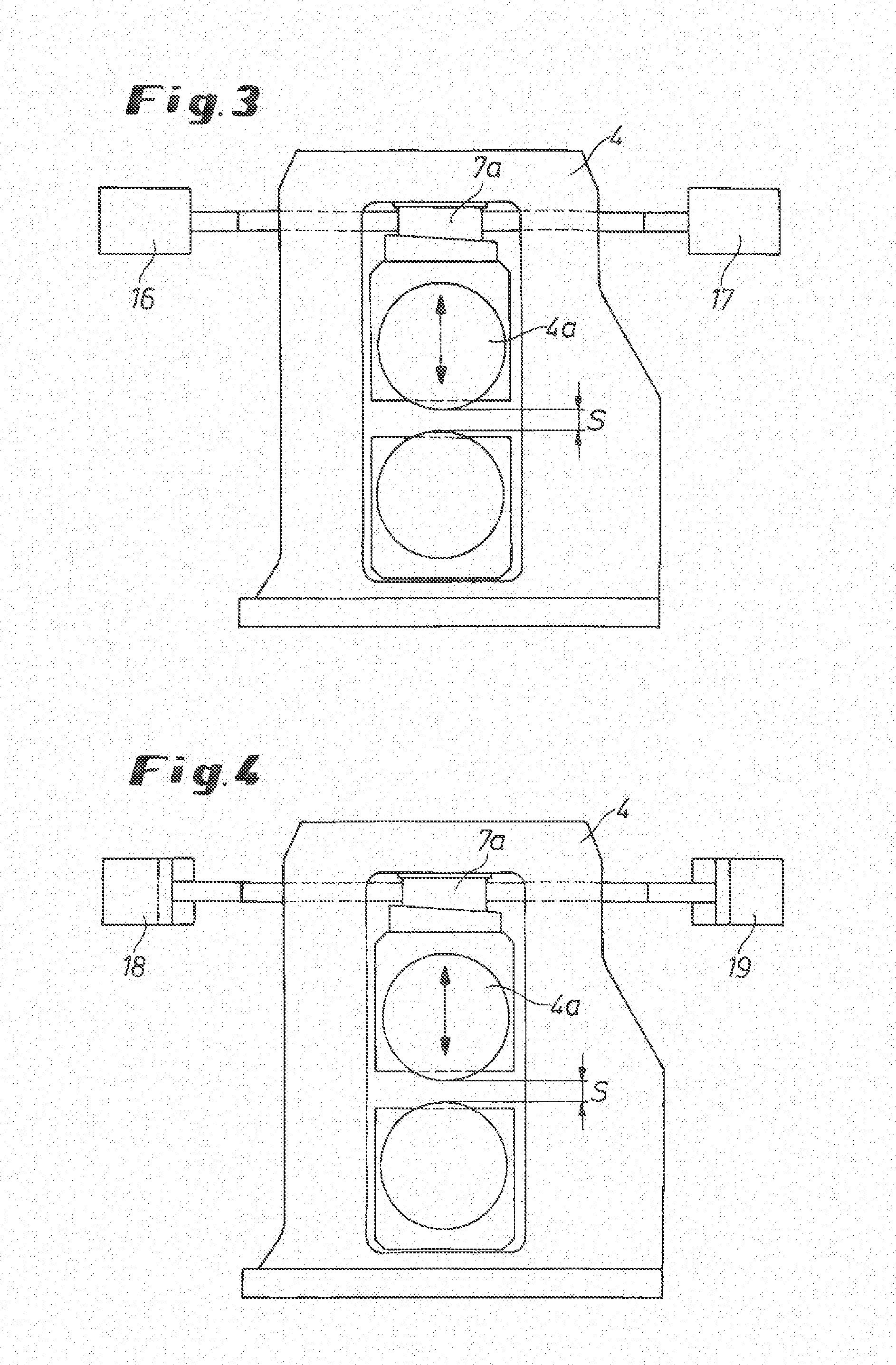

[0037]FIG. 3 is a schematic side view of second embodiment of the invention where an adjustment wedge 7a can be moved horizontally in the direction D for shifting the upper roll 4a by electric or hydraulic motors 16 and 17, in order to adjust roll gap S in the desired manner.

[0038]FIG. 4 is a schematic side view of a third embodiment of the invention in which, unlike the first and second embodiments of FIGS. 1 through 3, the lateral movement of adjustment wedge 7a is effected by hydraulic cylinders 18 and 19. In this case as well, the horizontal movement of the adjustment wedge 7a produces vertical movement of the upper work roll 4a and an adjustment of roll gap S in the desired manner.

fourth embodiment

[0039]FIG. 5 shows a fourth embodiment that is variant of the system of FIG. 4 in which a pump 20 driven by a motor 21 controls the flow of oil to the hydraulic cylinders 18 and 19. In a preferred approach, both the pump 20 and the motor 21 are attached in a fixed manner to the roll-stand frame 4 so as to limit to the necessary minimum the installation space of roll stand together with all of its ancillary modules.

[0040]FIG. 6 is a side schematic view of a fourth roll stand according to the invention. A vertically effective hydraulic cylinder 22 functions directly and without the use of adjustment wedges or the like to shift the upper work roll 4a and thereby adjust the roll gap S in the desired manner. The vertical adjustment of the piston inside the hydraulic cylinder 22 is effected by supplying the hydraulic fluid under pressure P from an external source.

fifth embodiment

[0041]FIG. 7 is a schematic side view of the invention. Adjustment of the roll gap S by adjusting the vertical position of the upper work roll 4a is effected here by a spindle 23 that functions as an element supporting the upper work roll 4a. The spindle 23 is vertically fixed in the stand 4 and threaded into a large nut rotatable by a motor 24, and thus effects not only the stepless adjustment of roll gap S by means of the vertical position of work roll 4a but also the fixation of upper work roll 4a in the desired position.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com