Fitting Contact Lenses for Irregular Corneas

a technology of contact lenses and irregular corneas, applied in the field of soft contact lens fitting, can solve the problems of corneal deviance, corneal irregularity, and impaired vision of subjects with irregular corneas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

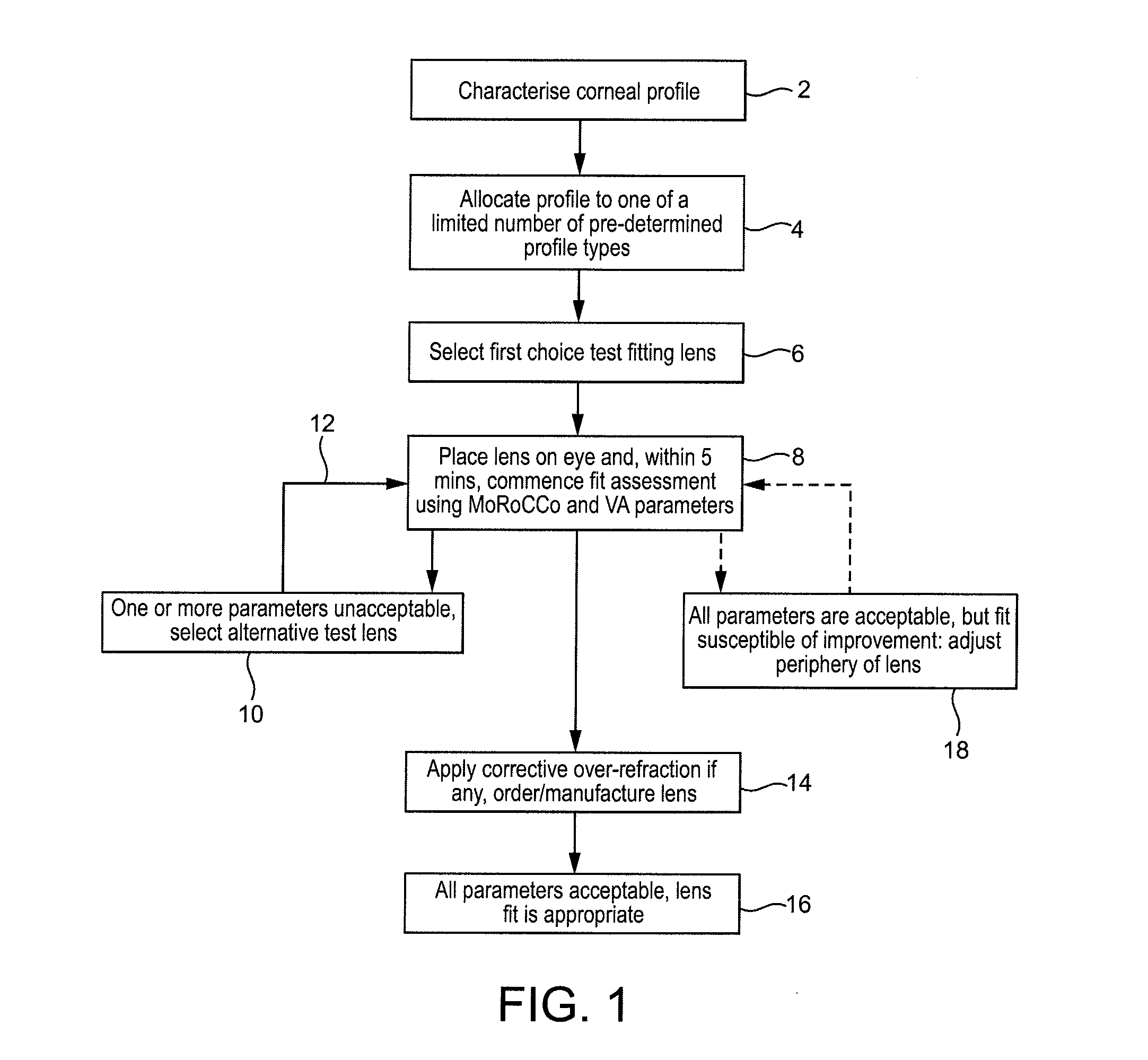

Method used

Image

Examples

example 2

Subject with Central Keratoconus

[0109]Identifying Corneal Shape[0110]Spectacle Rx+0.25 / −2.75×103 VA 6 / 15[0111]Sim Ks: 7.32 / 6.78[0112]Steepest curvature (Inferior): 6.34 mm radius[0113]Flattest curvature: 7.93 mm radius[0114]Curvature of “green area” on topography: 7.30[0115]Corneal Astigmatistm: −4.98×141@ 3 mm[0116]−3.48×143 @ 5 mm

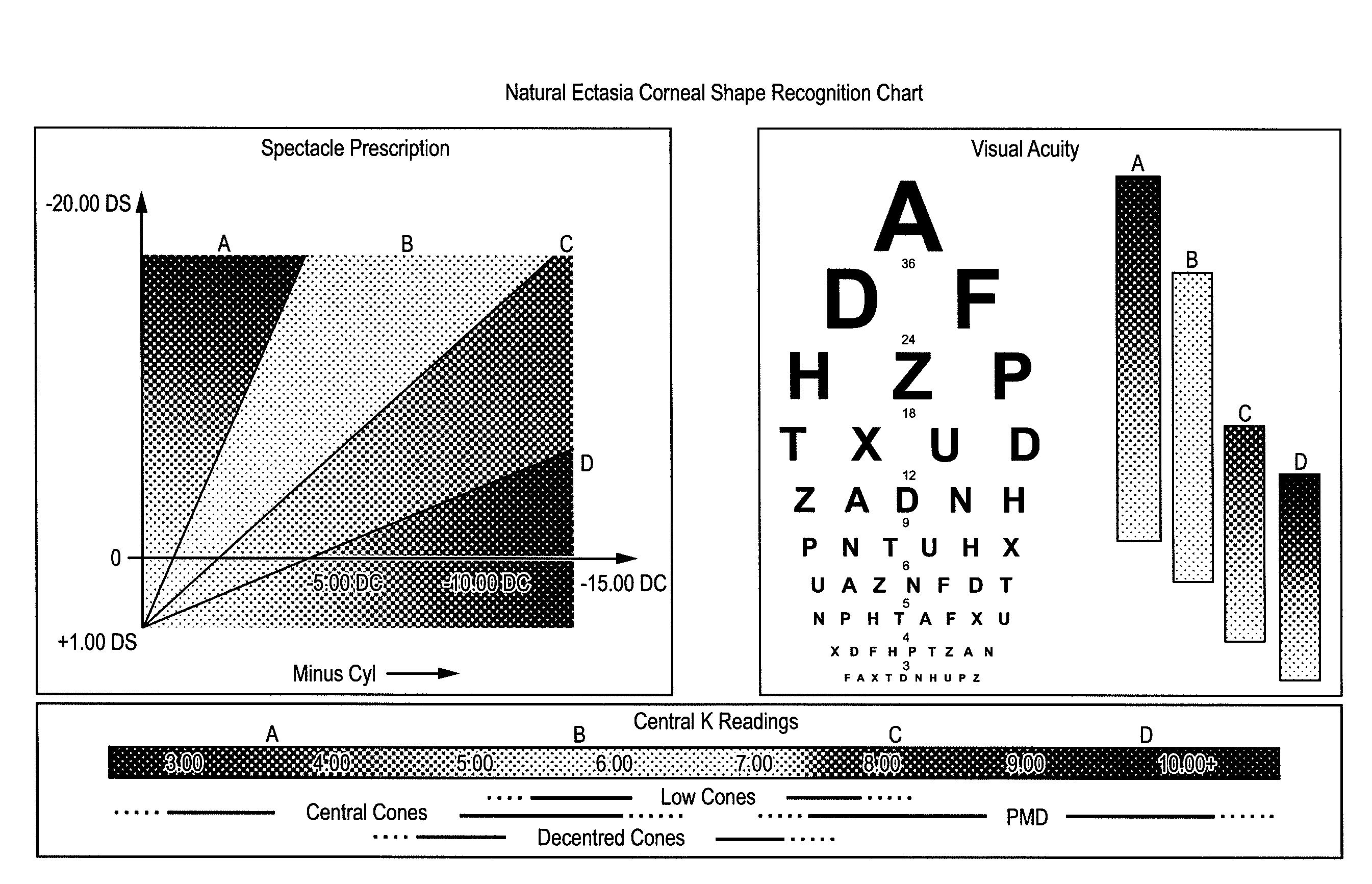

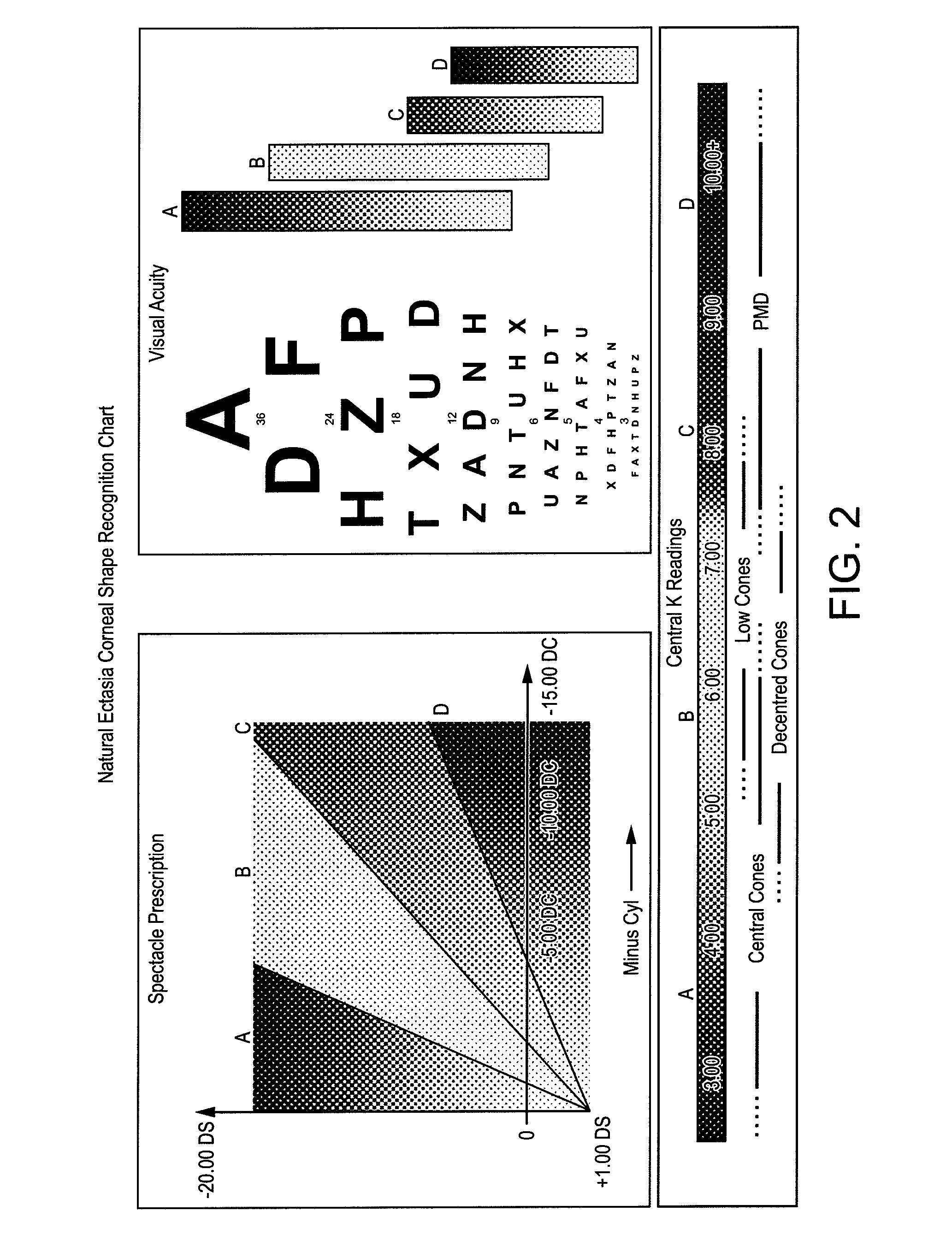

Corneal Shape Recognition Chart

[0117]This cornea demonstrated reasonably normal K readings with a low spectacle Rx but with the central acuity affected significantly. This is typical of mild central ectasias, as any distortion on the visual axis impacts on VA.

[0118]The corneal topography, analysed using a corneal topographer instrument, had a pattern reminiscent of low cones / PMD but the central location of a steep area confirmed keratoconus. The curvature of the “green” area and the flattest curvature value showed that this cornea had a relatively steep periphery.

First Choice Lens

[0119]Even though this was a case of mild keratoconus, the cornea had a rela...

example 3

Subject with Decentred Cone

History

[0143]Subject diagnosed with keratoconus 14 years previously and had worn RGP lenses since. (VA this eye 6 / 12). The cornea had central scarring and significant staining with fluoresein. Due to the current discomfort, the patient elected to go without a lens until the cornea had demoulded.

Identifying Corneal Shape

[0144]Spectacle Rx: +1.25 / −6.25×50 VA 6 / 15[0145]Sim Ks: 6.13 / 5.39[0146]Steepest curvature: 4.75 mm radius[0147]Flattest curvature: 9.30 mm radius[0148]Curvature of “green area” on topography: 7.50

Corneal Astigmatism: −7.58 D ax 11 at 3 mm

[0149]−6.56 D ax 41 at 5 mm

Corneal Shape Recognition Chart

[0150]In this case, the spectacle refraction had been affected by central scarring and thus the normal relationship between refraction and corneal shape had been changed. Decentred cones often demonstrate oblique axes, which can be a useful clue if topography is not available. This cornea demonstrated a very flat periphery on topography but this may n...

example 4

Subject with Low Cone

History

[0184]Subject diagnosed with Pellucid Marginal Degeneration 4 years previously and had a Corneal Collagen Cross linking (CXL) procedure 6 months previously. He had not used his RGP lenses since then and now wished to be refitted into soft lenses.

Identifying Corneal Shape

[0185]Spectacle Rx:+1.50 / −8.00×120 VA 6 / 19[0186]Sim Ks: 6.55 / 5.68[0187]Steepest curvature (Inf): 6.61 mm radius[0188]Flattest curvature: 8.80 mm radius[0189]Curvature of “green area” on topography: 7.00[0190]Corneal Astigmatism: −7.81×128 @ 3 mm[0191]−6.80×131 @ 5 mm

Corneal Shape Recognition Chart

[0192]Although the topography map showed a classical PMD “crabs claw” pattern and the Spectacle Acuity also indicated this condition, in this case, the steepest area of curvature was relatively high and was thus better described as a low cone. A “Low cone” condition was also suggested from the central K readings and the poor Spectacle Acuity, which was caused by the rapid changes of curvature with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com