Snap fitting for plumbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

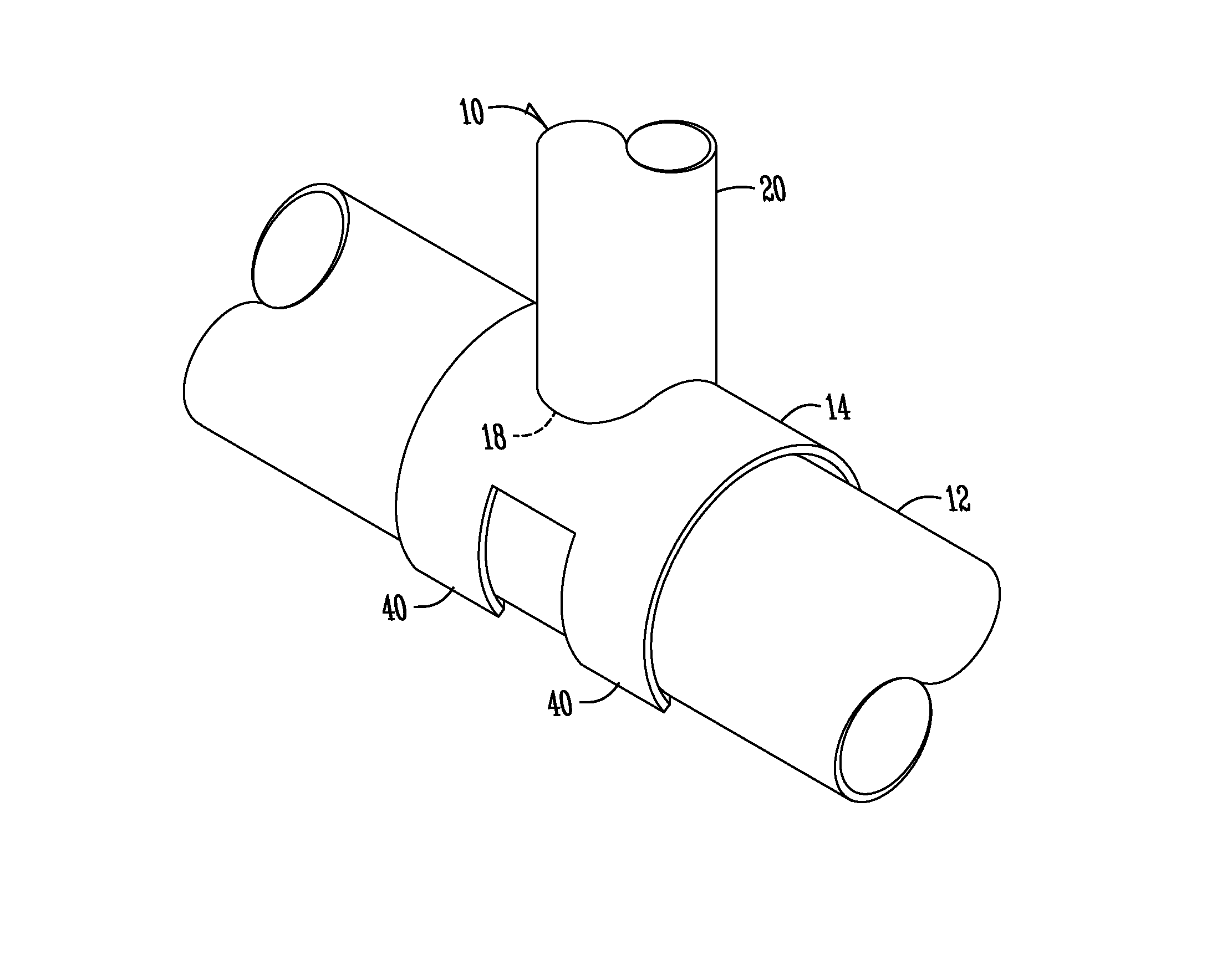

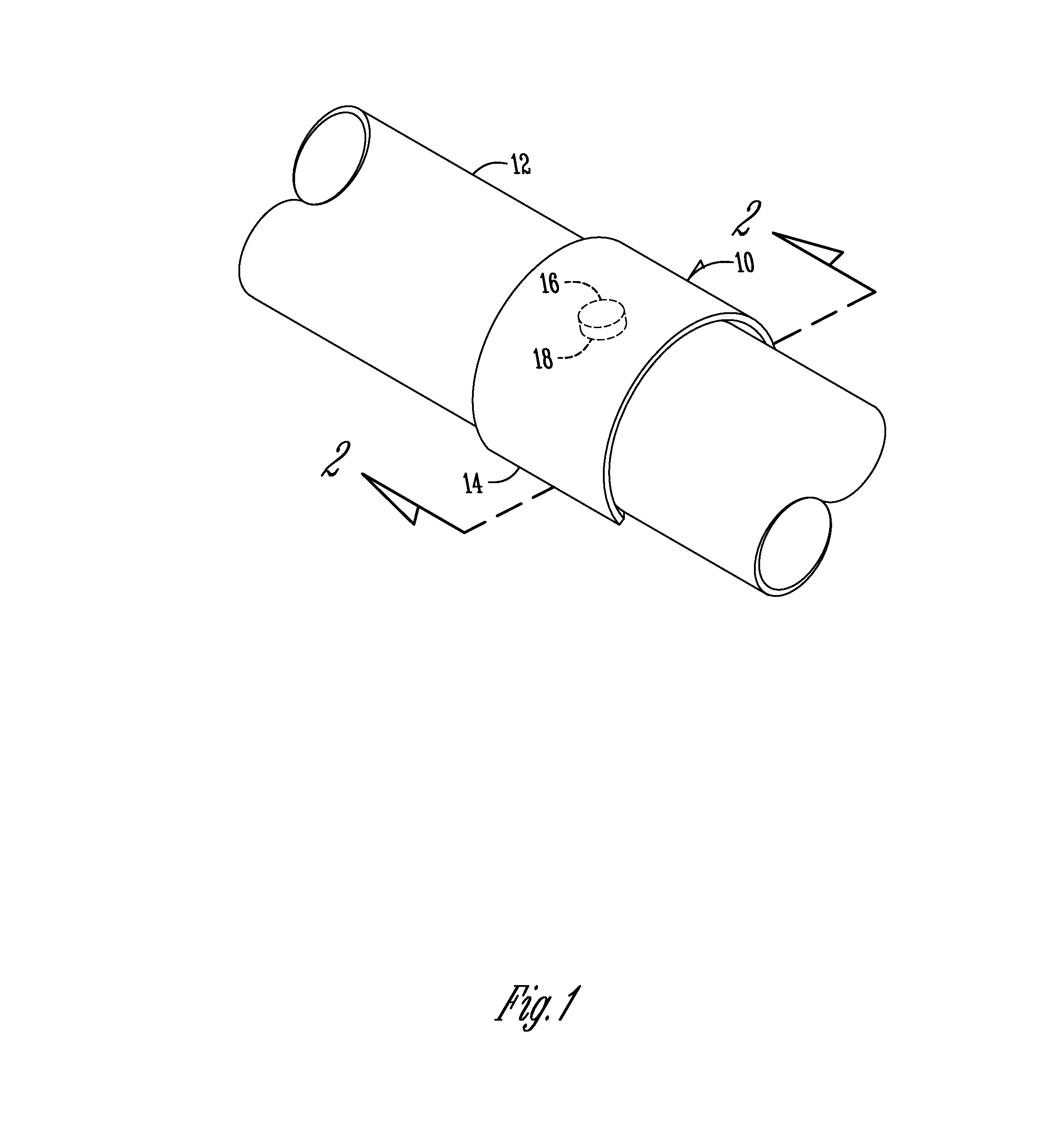

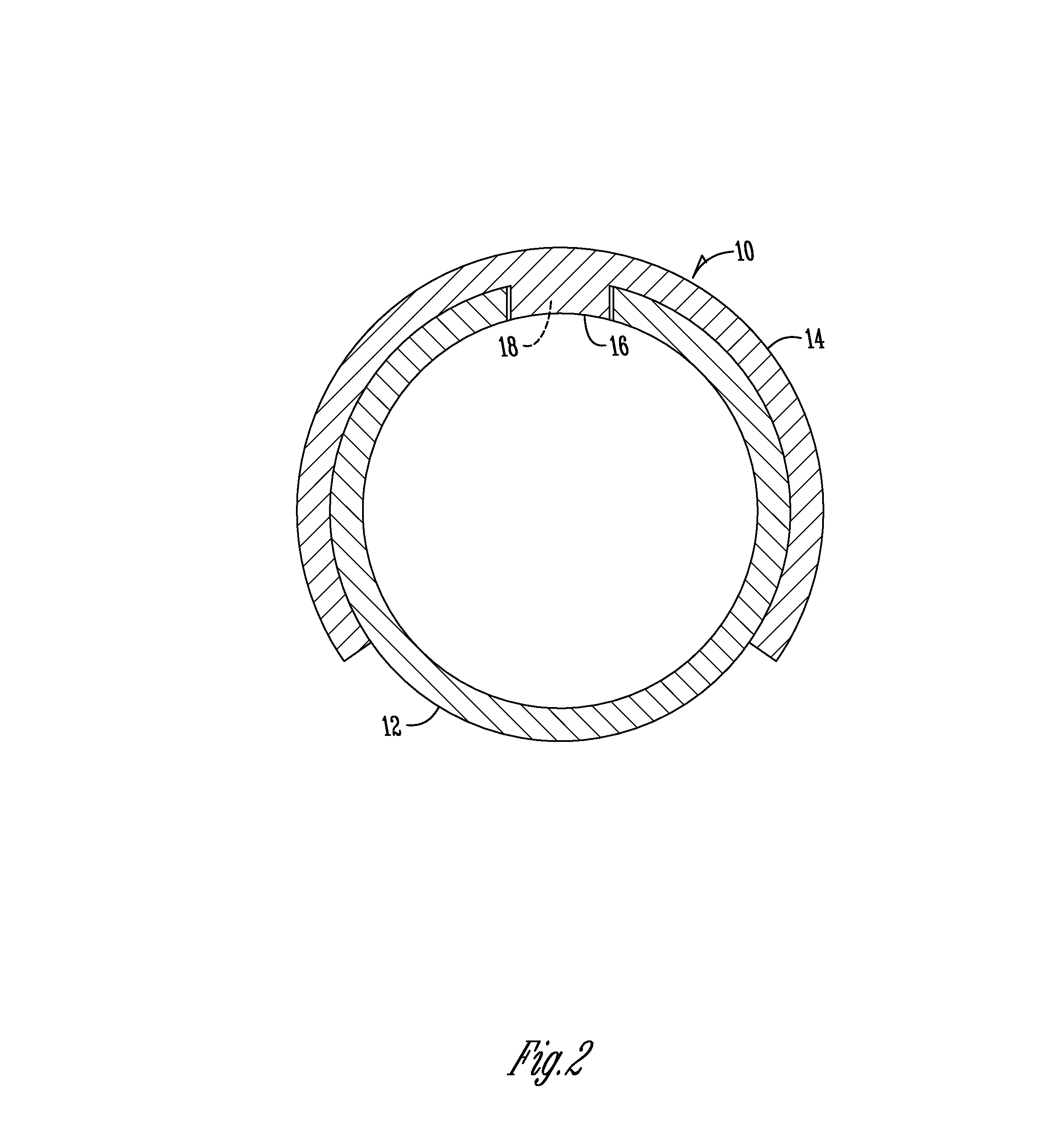

[0025]FIG. 1 illustrates a snap fitting 10 positioned on a pipe 12. The snap fitting 10 has a main body 14 which extends generally annularly around a portion of the pipe 12. The main body 14 preferably extends over 50 percent around the pipe 12 which allows the snap fitting 10 to snap fit in place. Although not shown, solvents and glues may coated on the interior of the main body 14 and the exterior of the pipe 12 to attach the fitting 10 to the pipe 12.

[0026]There is an inset 16 which may be an integral portion of the snap fitting 10 or may be a separate piece which is attached to the snap fitting 10 (such as through a solvent cement or otherwise). The inset 16 fits within a hole 18 in the pipe 12 to plug the hole 18.

[0027]The snap fitting 10 may be made out of any number of plastic materials. One such type of material which is used in plumbing is polyvinylchloride, although other types of plastic materials may be used. The snap fitting may have a wall thickness substantially the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com