Pattern inspection device and pattern inspection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Hereafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0038]The embodiments of the present invention will be described in the following order:

[0039]1. Configuration of pattern inspection device

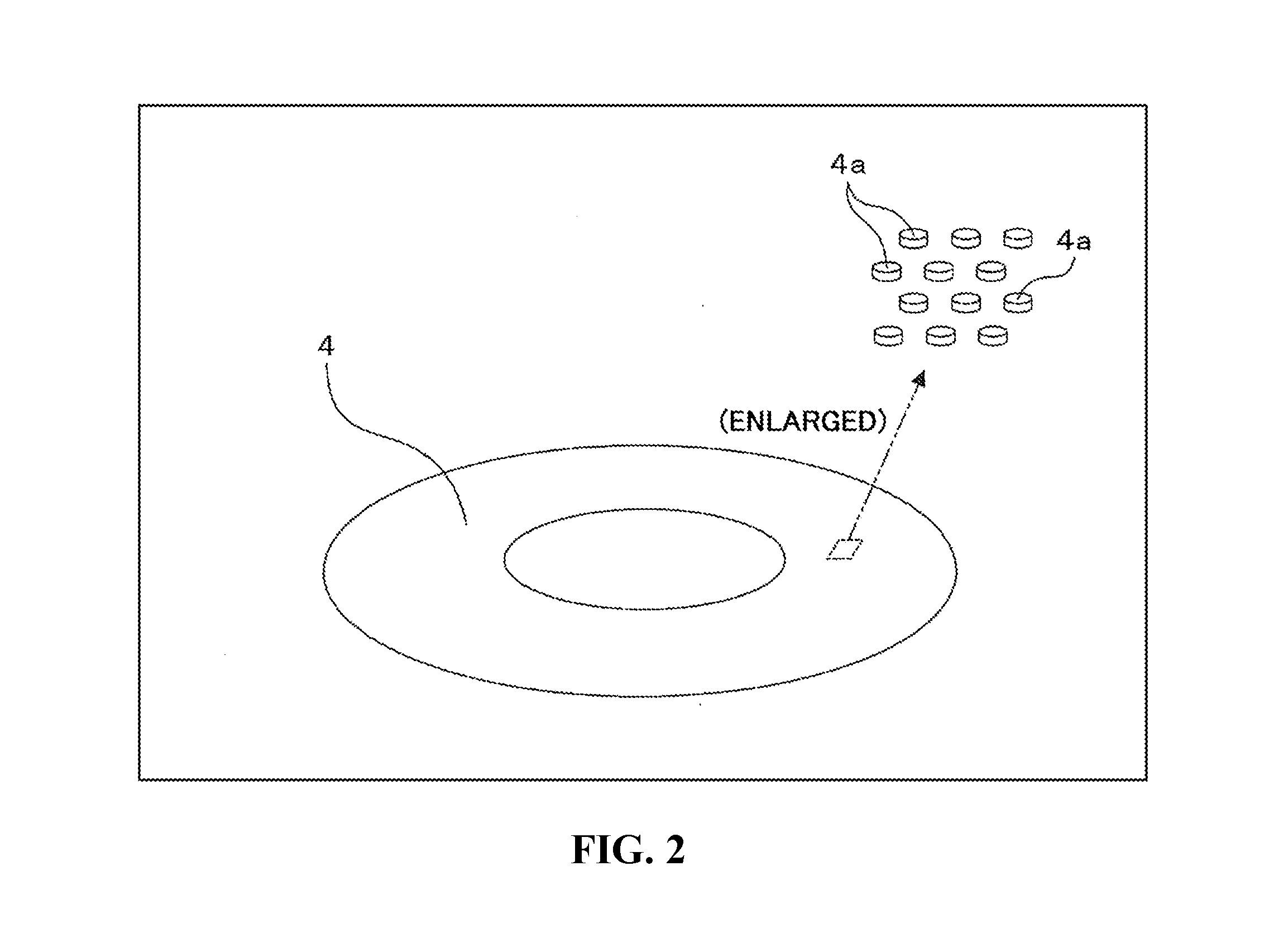

[0040]2. Structure of disk medium

[0041]3. Pattern inspection method

[0042]4. Effects of the embodiments

[0043]5. Modifications

[0044]

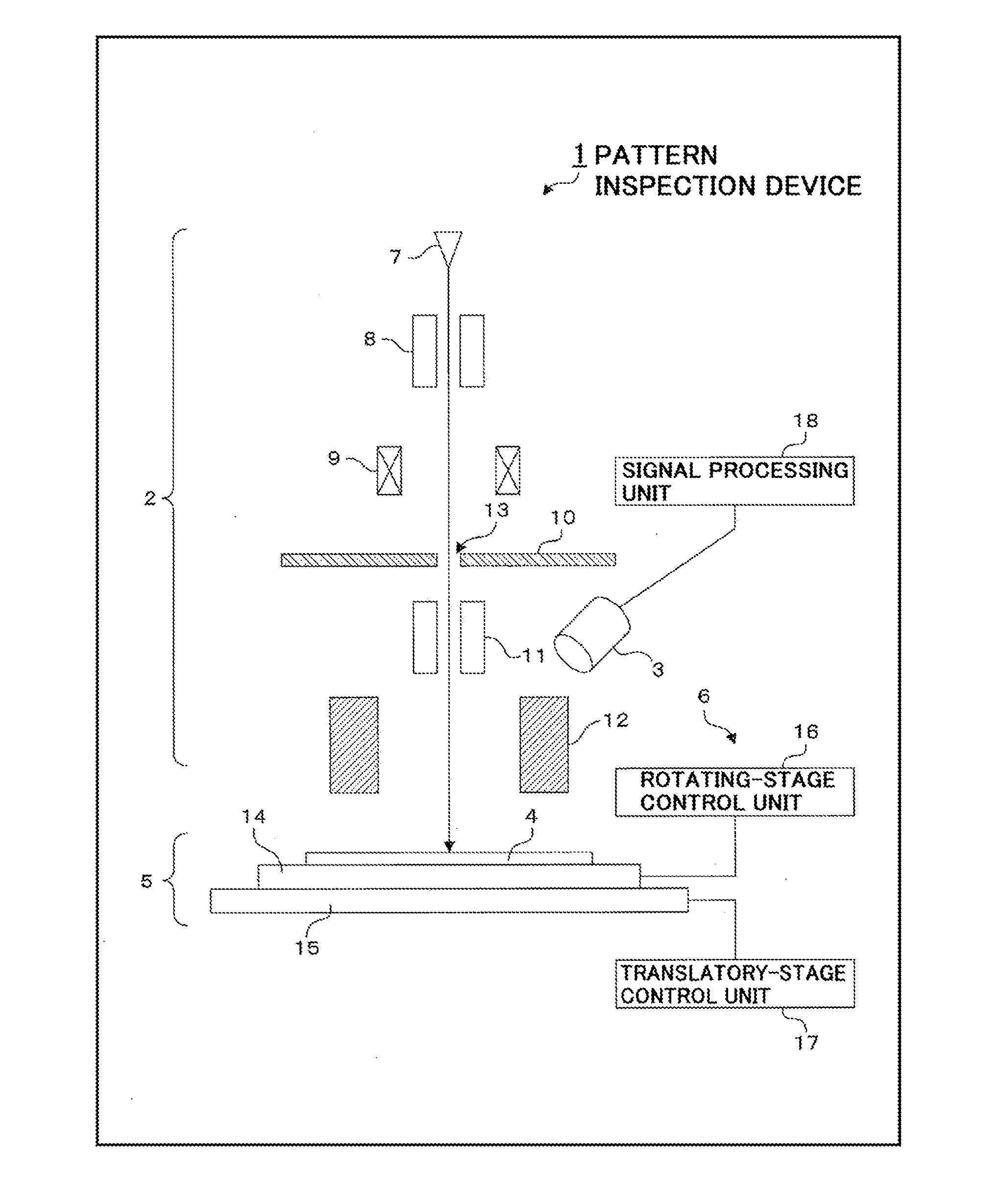

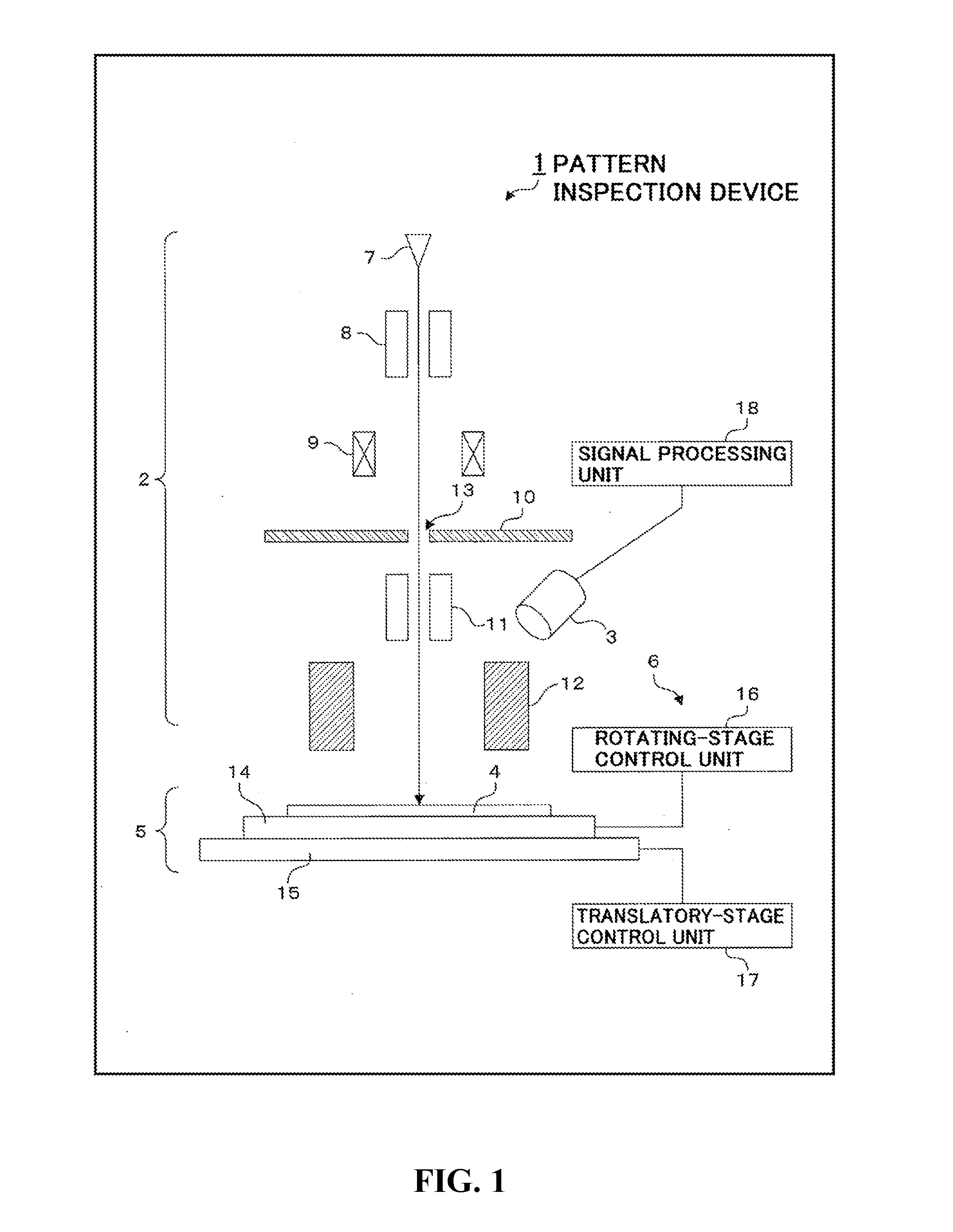

[0045]FIG. 1 is a schematic diagram showing a configuration example of a pattern inspection device according to an embodiment of the present invention. The illustrated pattern inspection device 1 mainly includes an irradiating optical system 2 for radiating an electron beam, an electron detector 3 for detecting an electron, a stage mechanism 5 for supporting a disk medium 4 which is a pattern inspection target, and a stage control system 6 for controlling the drive of the stage mechanism 5.

[0046](Configuration of Irradiating Optical System)

[0047]The irradiating optical system 2 irradiates the disk medium 4 p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap