Riser platform

a platform and platform technology, applied in the field of platform, can solve the problems of common wet or dank spots, flooding and water inundation, and the floor surface in storage areas is therefore unsuitable for placement, and achieve the effect of saving shipping costs and increasing load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The following detailed description and the appended drawings describe and illustrate exemplary embodiments of the invention solely for the purpose of enabling one of ordinary skill in the relevant art to make and use the invention. As such, the detailed description and illustration of these embodiments are purely exemplary in nature and are in no way intended to limit the scope of the invention, or its protection, in any manner. It should also be understood that the drawings may not be to scale and in certain instances details have been omitted, which are not necessary for an understanding of the present invention, such as conventional details of fabrication and assembly.

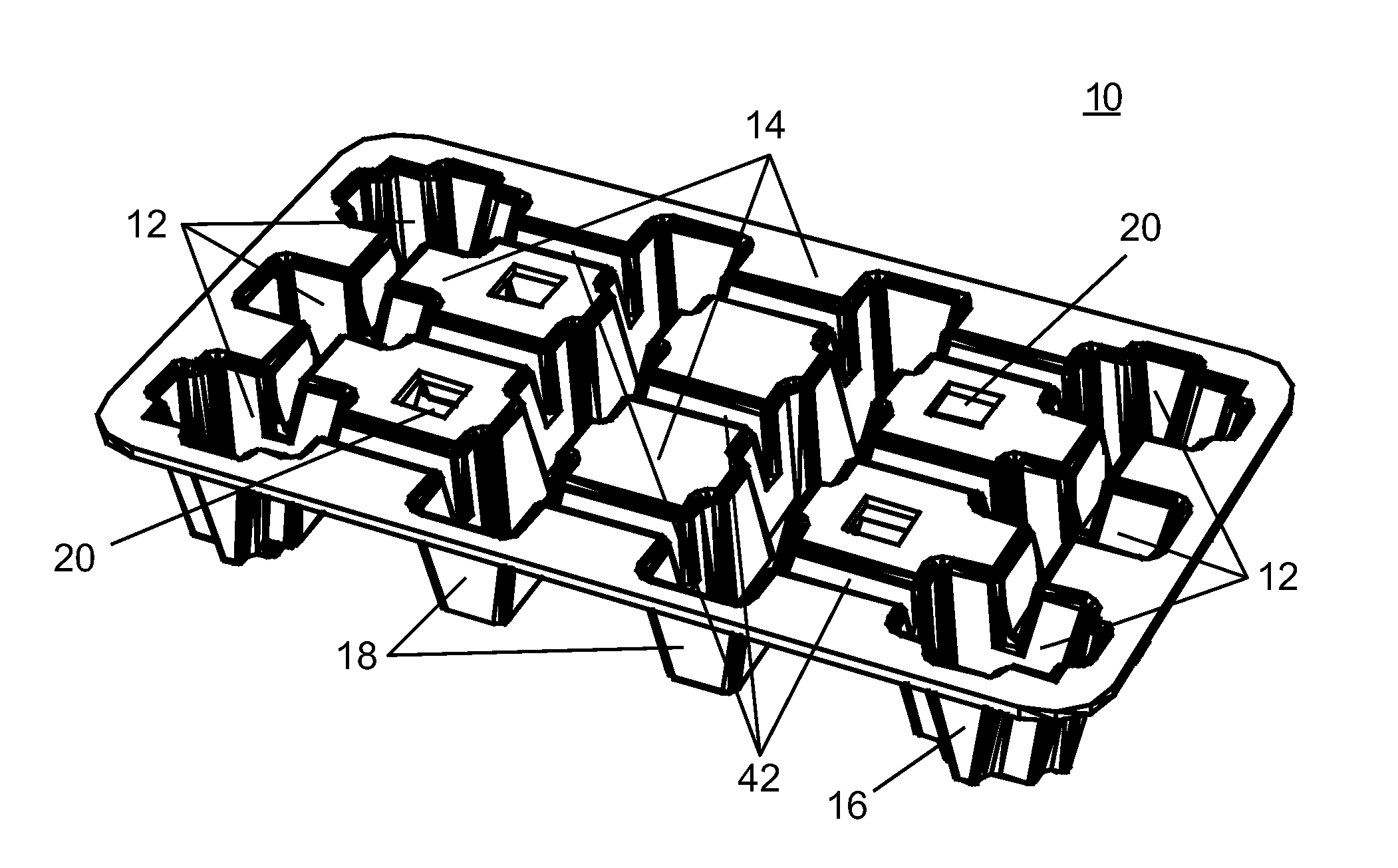

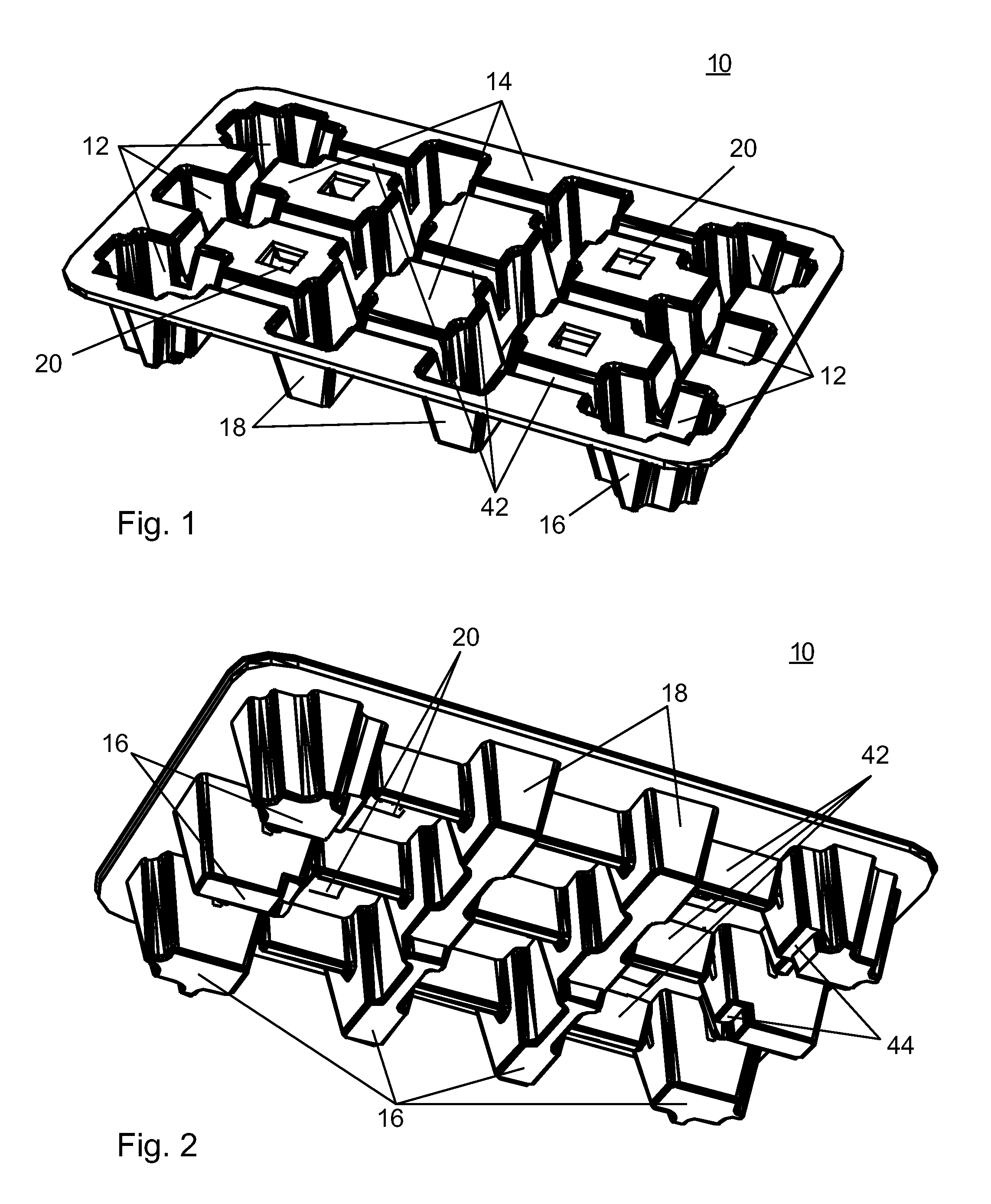

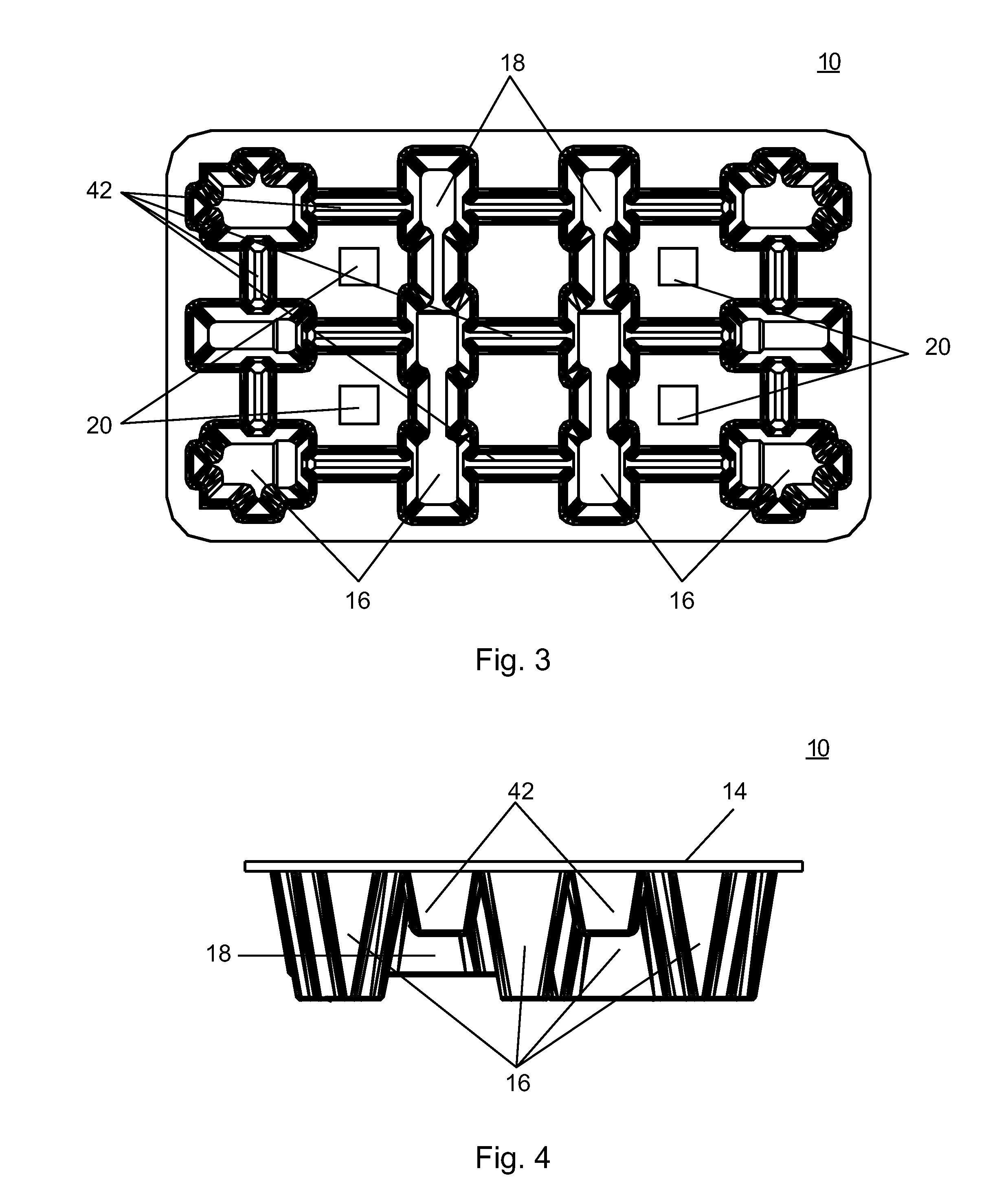

[0039]Referring to the drawings, FIGS. 1-5 illustrate an environmentally friendly, lightweight, sturdy, water-resistant, mold-resistant, molded pulp fiber riser platform 10 according to one aspect of the present invention. Riser platform 10 has an upper surface 14 that is supported by columns 16 and 18. Column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com