Processes for producing antitoxic fibers and fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

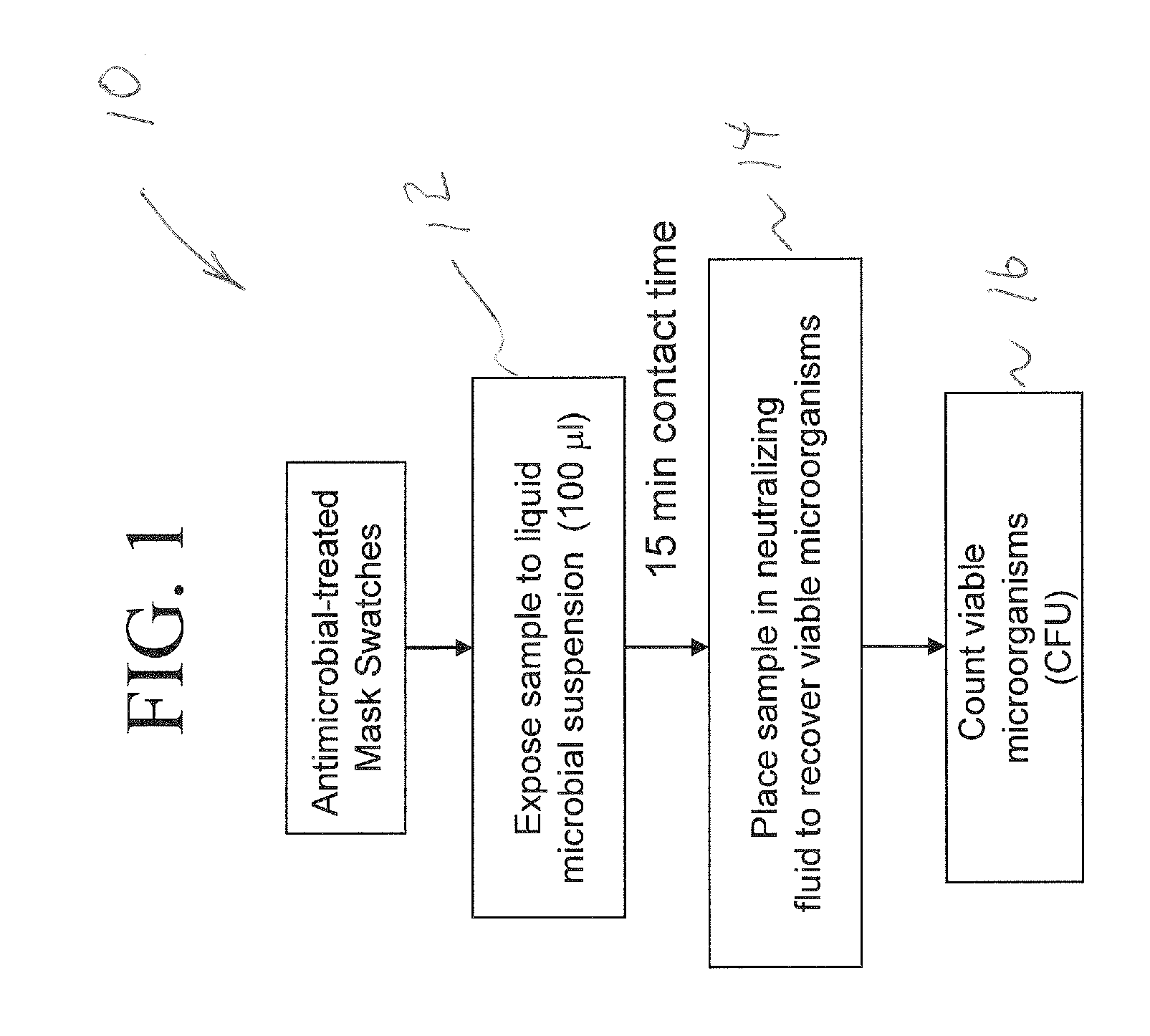

Method used

Image

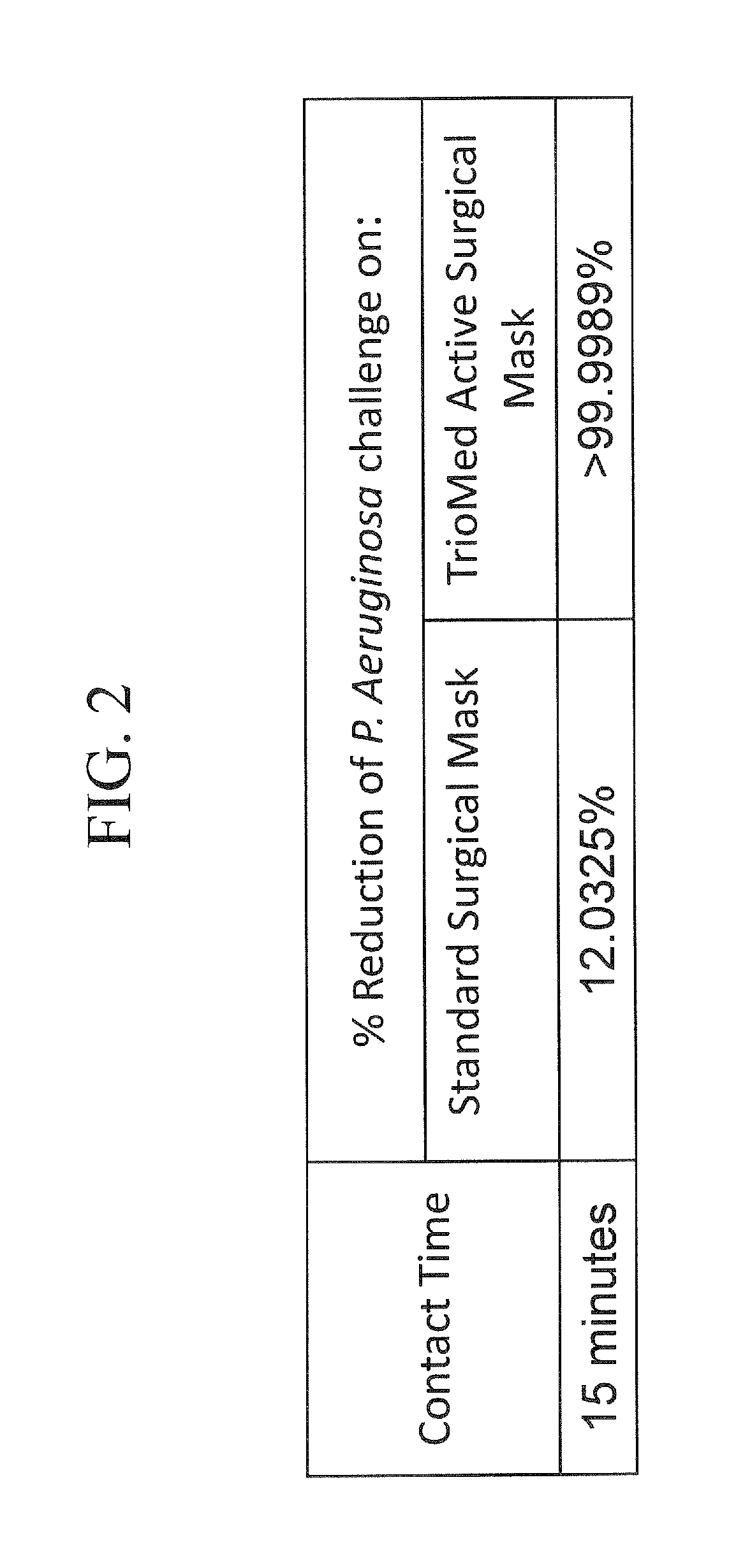

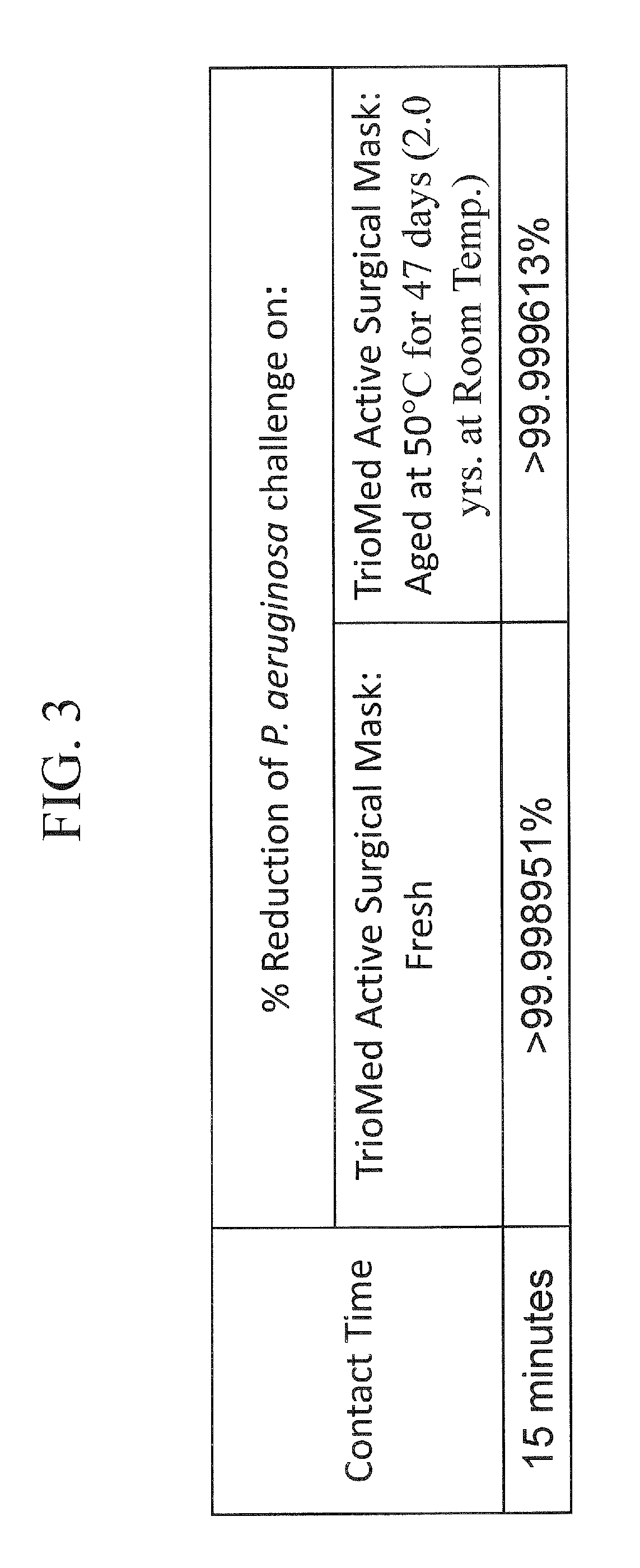

Examples

example 1

Preparation of Triiodide Solution

[0081]A. Prepare 1N iodine (129,600 ppm I2):[0082]1. In a 1 L volumetric flask, add approx 250 mL high purity water[0083]2. Weigh out 175 g of KI solid and add to the 1 L flask containing the water[0084]3. Swirl solution in flask to dissolve all KI.[0085]4. Weigh out 130 g of Iodine solid and add to the 1 L flask containing the KI and water solution[0086]5. Fill the volumetric flask with high purity water to the marked line[0087]6. Add a magnetic stir bar to the flask[0088]7. Cap the flask with a glass stopper[0089]8. Cut a piece of parafilm and wrap it around the top of the flask / stopper to prevent any leakage[0090]9. Take the flask and place it on a magnetic stir plate.[0091]10. Set stir control to 7 and let the solution mix overnight to dissolve all iodine solid[0092]11. Dilute according to needs

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com