Abrading arrangement to abrade a surface of an item and method of use thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

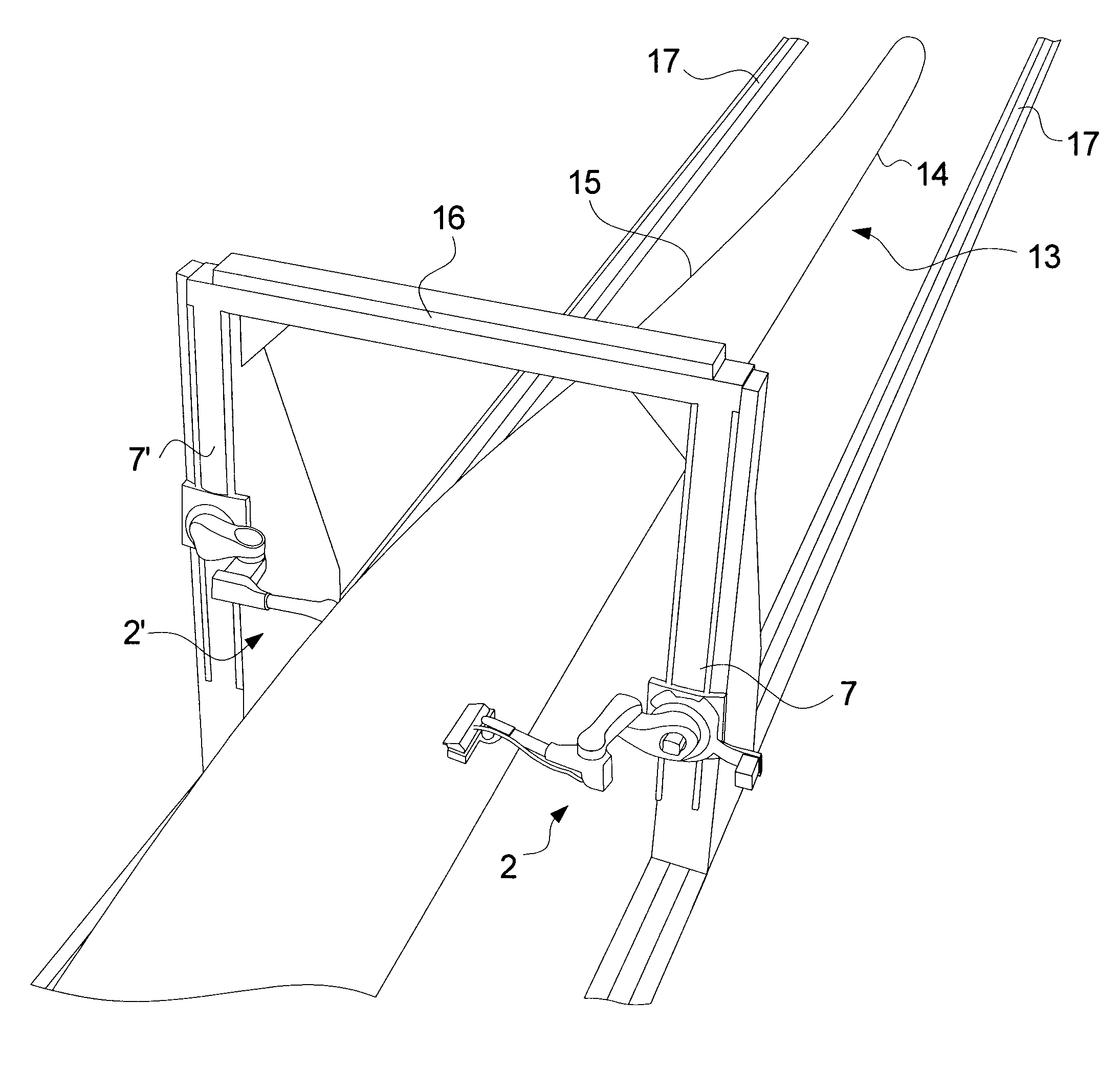

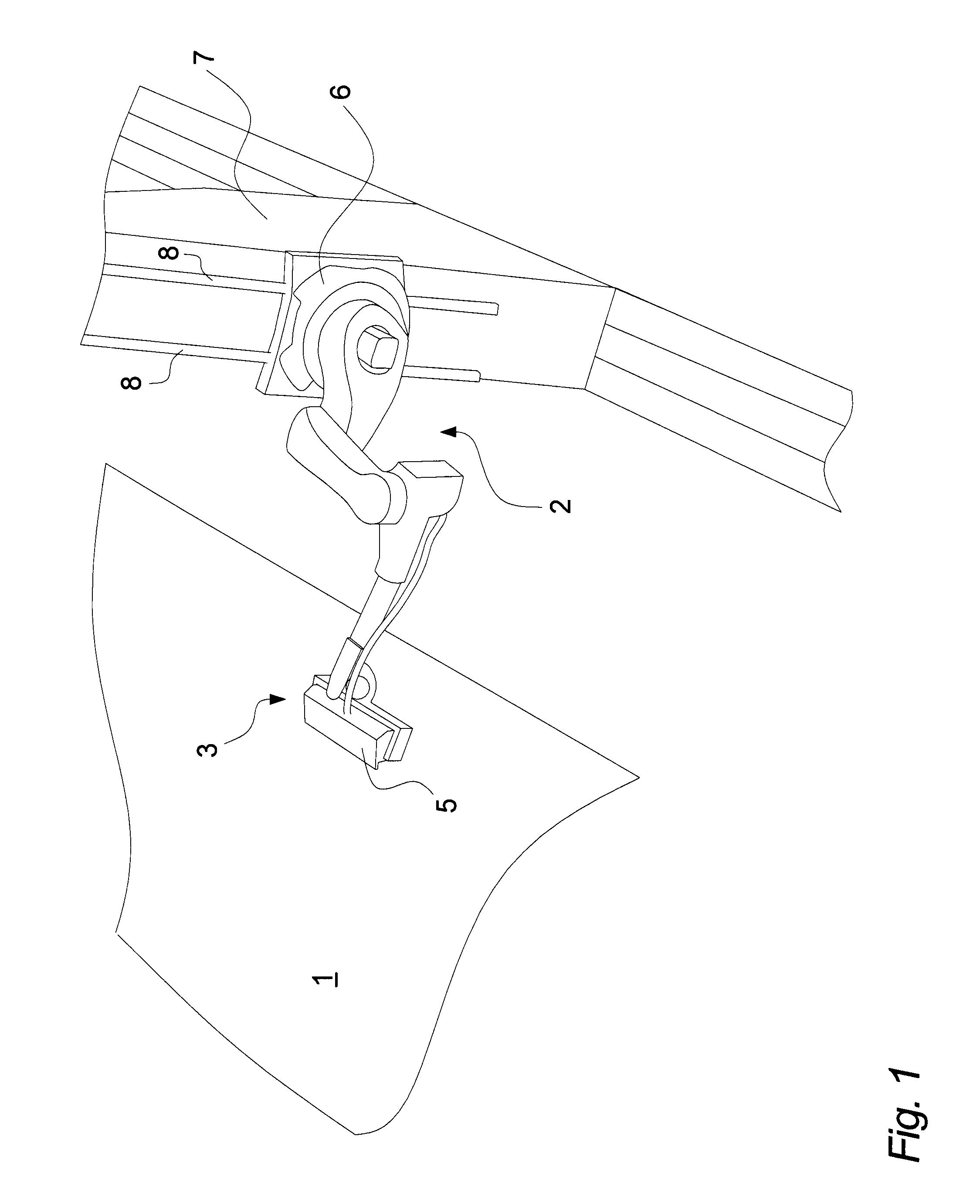

[0029]An abrasion arrangement of the present invention for abrading of a surface 1 is shown in FIG. 1 comprising a 6-axis articulated robotic arm 2 on which is mounted an abrasion head 3 having an abrading cylinder 4 enclosed in a shielding housing 5 provided with a suction outlet (not shown) for removal of dust and a motor (not shown) for driving the rotation of the abrading cylinder 4. The base 6 of the robotic arm 2 is in FIG. 1 mounted on a vertical column 7 equipped with parallel, vertical tracks 8 on which the base 6 is displaceable arranged in the vertical direction so as to enable abrasion of a surface 1 of a wider extent in the vertical direction than the robotic arm 2 itself allows for.

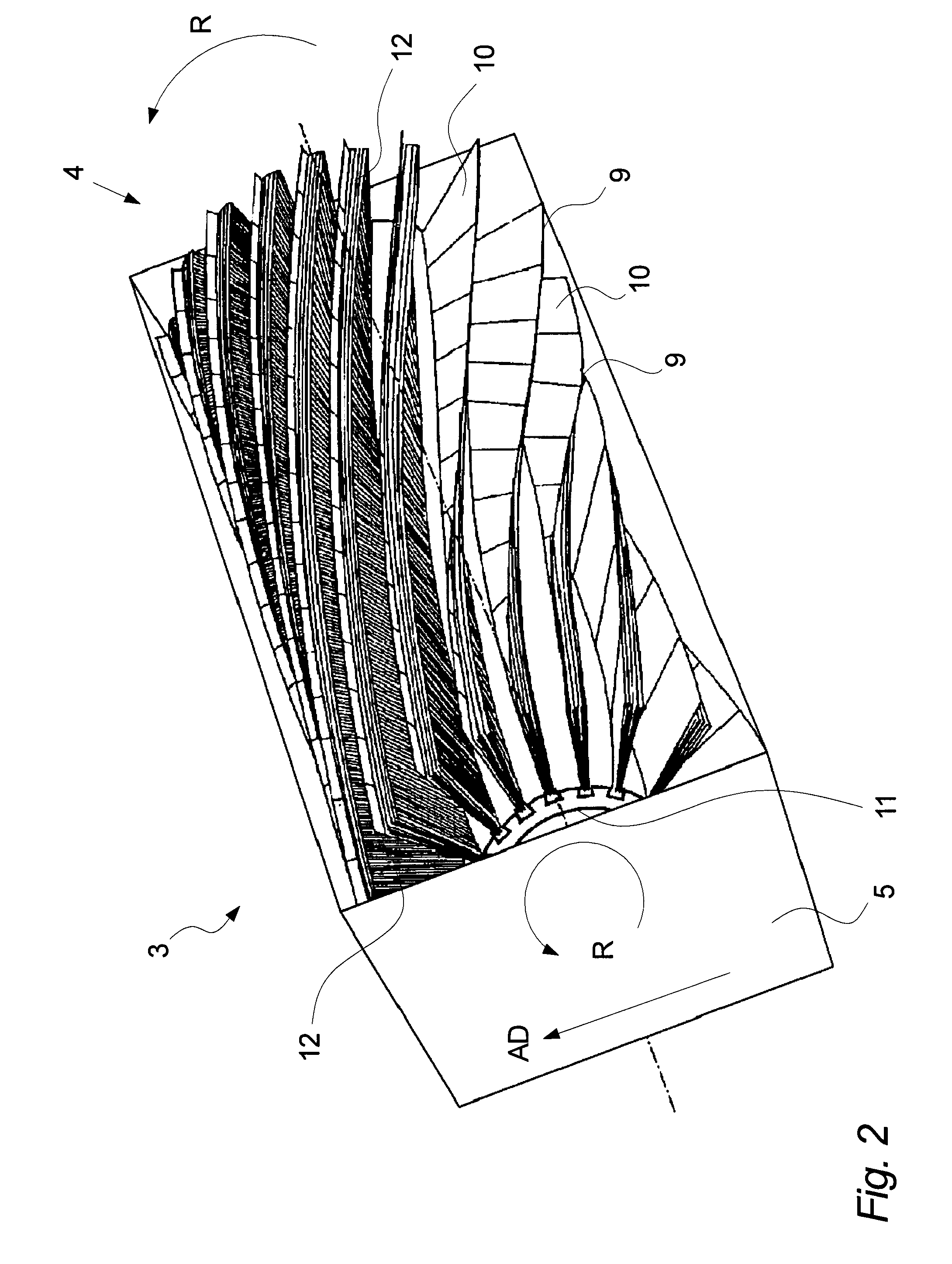

[0030]The abrading cylinder 4 shown in FIG. 2 has abrasive means which comprise abrasive lamellae 9 of an abrasive sheet, such as abrasive cloth, of which the front side 10 has abrasive properties and which extend substantially radially from an elongated core 11 of the cylinder. The abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com