Pressurizing pump structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

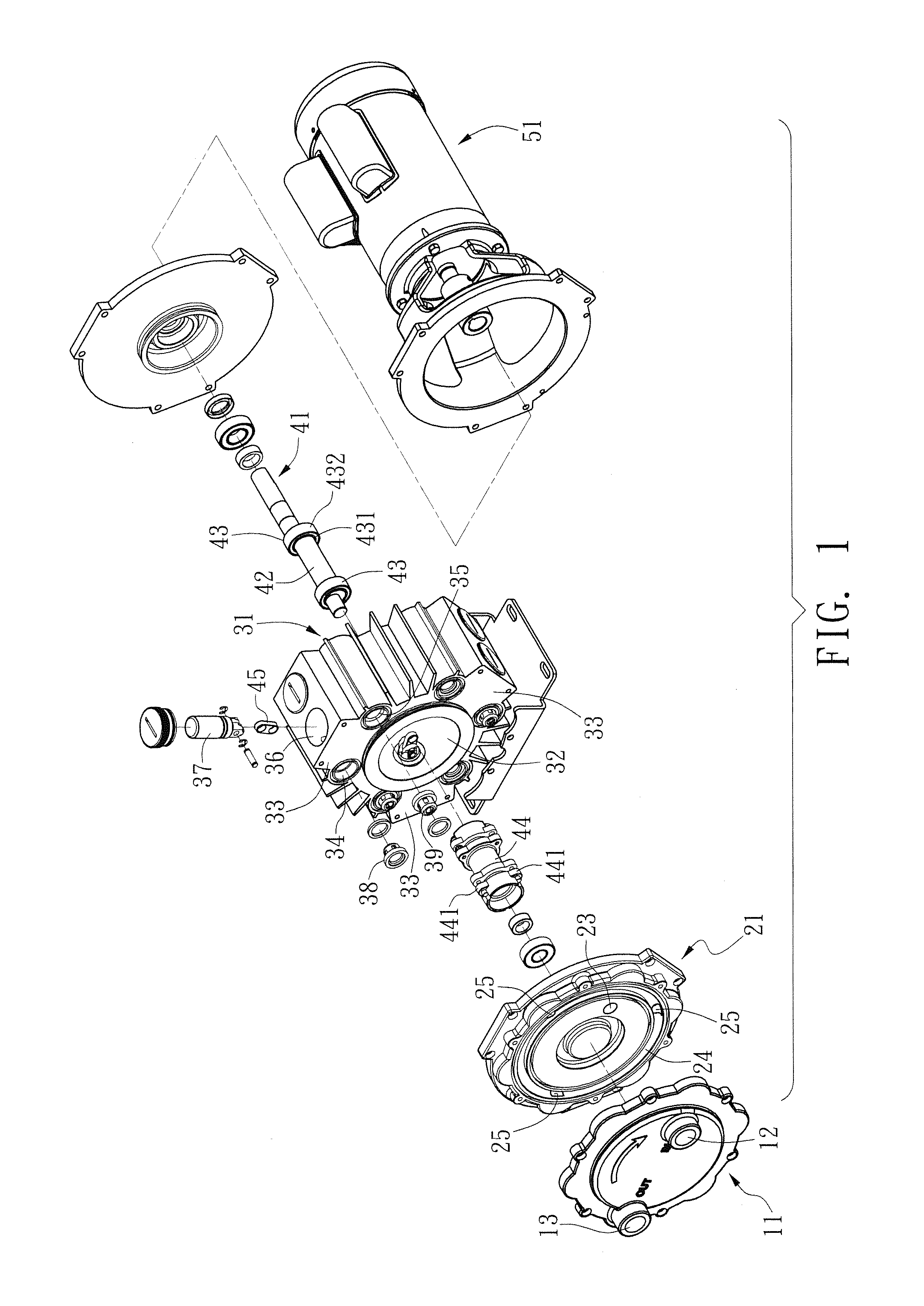

[0022]Please refer to FIGS. 1 to 4. The disclosed structure of a pressurizing pump consists mainly of a cover 11, a flow guide 21, a pump 31, and a main axle 41.

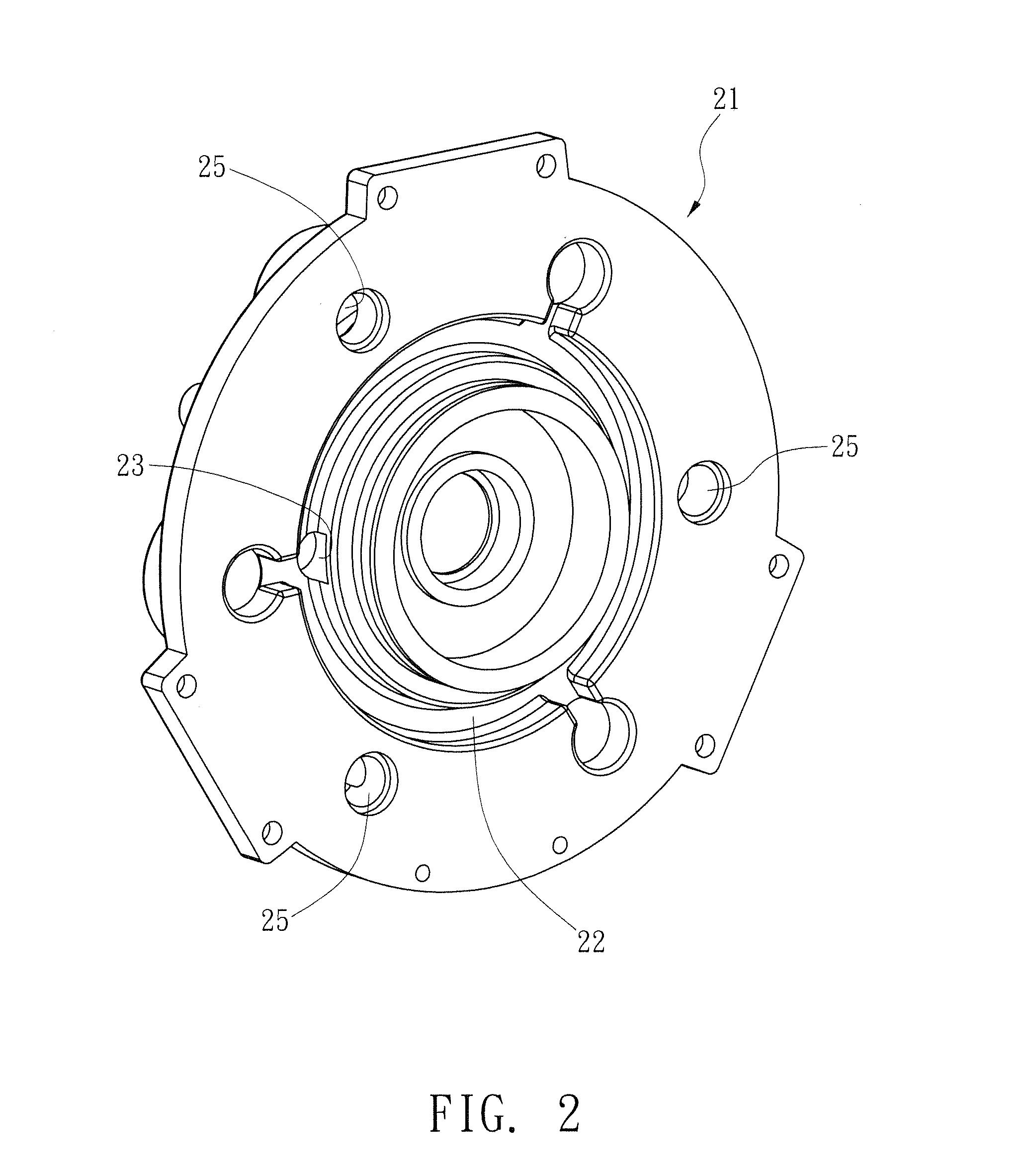

[0023]The cover 11 has an inlet 12 and an outlet 13. The flow guide 21 is interposed between the cover 11 and the pump 31.

[0024]The flow guide 21 has a disk shape. The side of the glow guide 21 facing the pump 31 is annually formed with a first passage 22. The flow guide 21 is formed with a first connecting hole 23 via which the first passage 22 is connected with the inlet 12. The side of the flow guide 21 facing the cover 11 is annually formed with a second passage 24 connected with the outlet 13. The second passage 24 is formed with a second connecting hole 25 that at least goes through the flow guide 21.

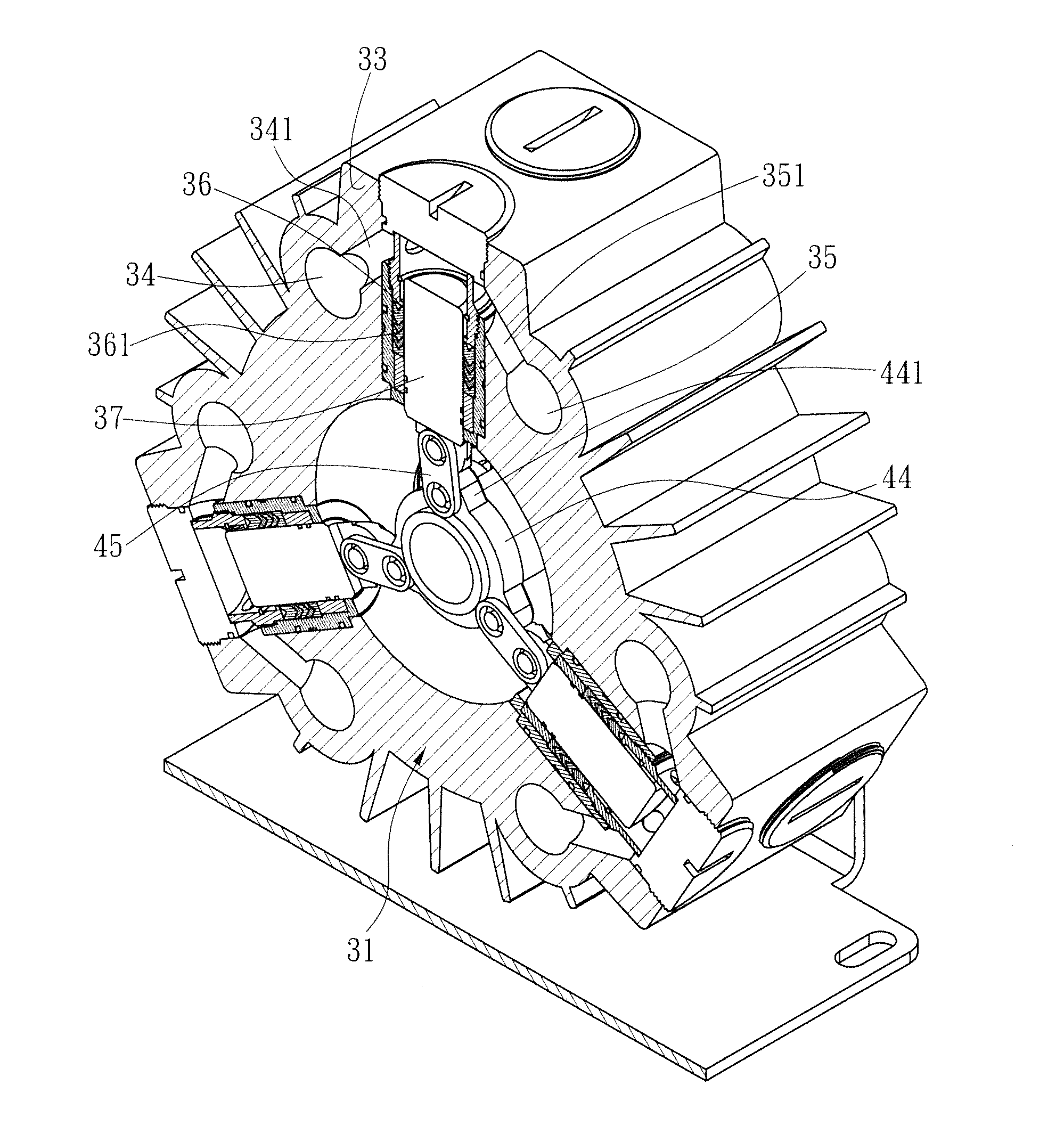

[0025]The pump 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com