Convective Airflow Using a Passive Radiator

a passive radiator and convective technology, applied in the direction of electrical transducers, transducer details, lighting and heating apparatus, etc., can solve the problems of reducing speaker performance and durability, introducing additional heat, and fan components in such devices can consume power, space, and consume additional heat, so as to increase the amount of heat removed, strengthen the structural integrity of the enclosure, and increase the effect of heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

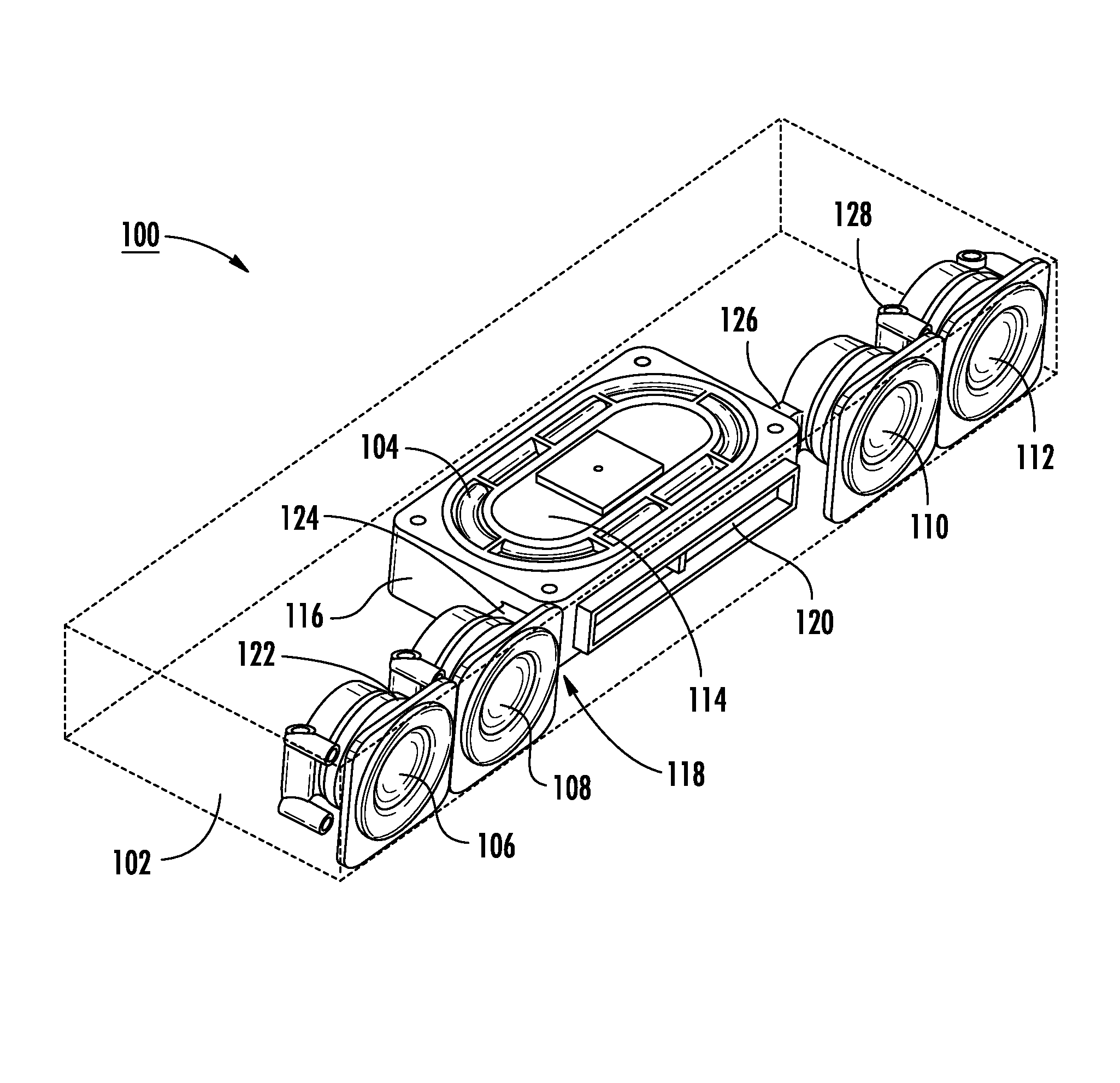

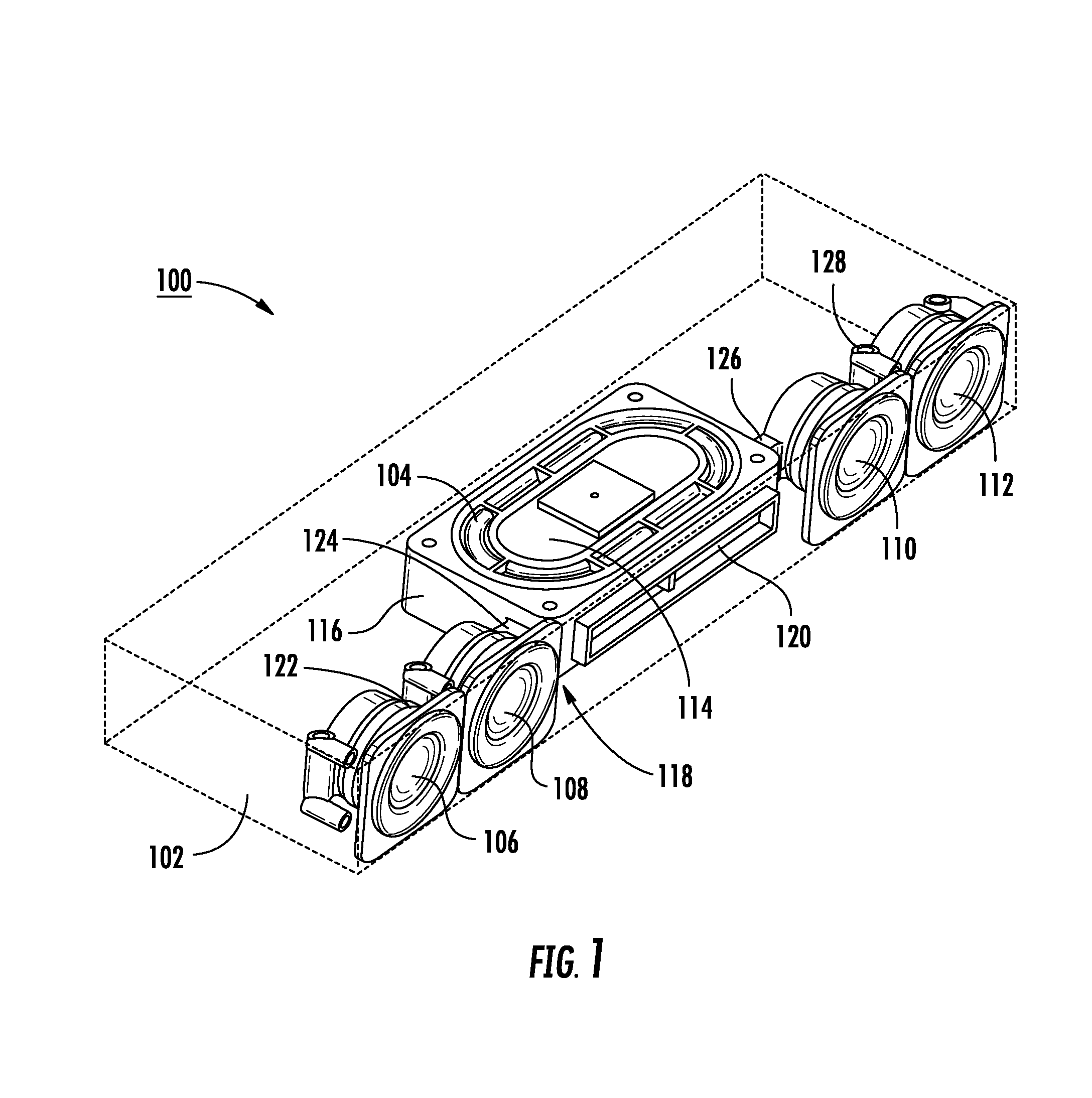

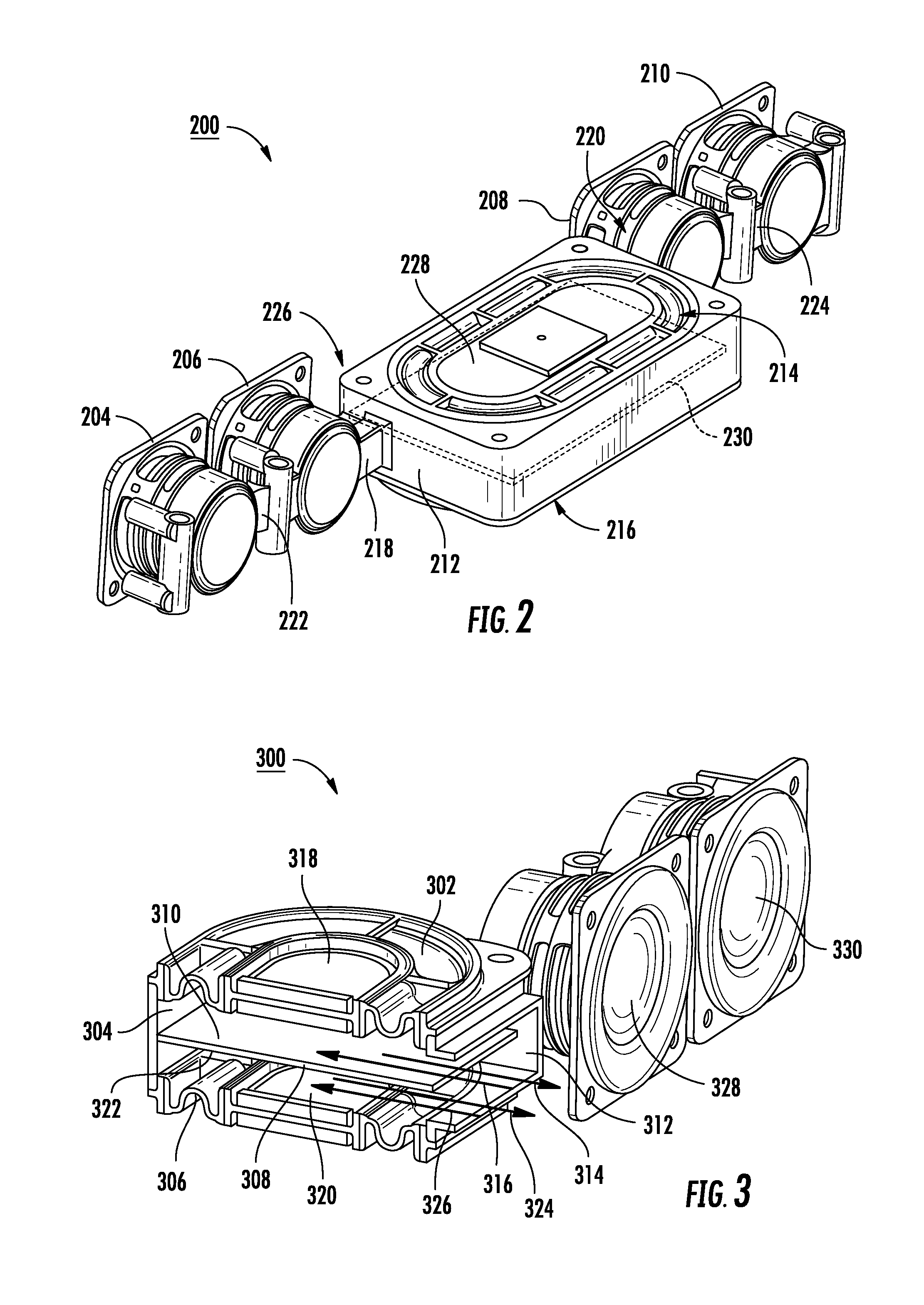

[0014]In a particular embodiment, an apparatus uses a passive radiator to create airflow that removes heat from an acoustic enclosure. A diaphragm of the passive radiator moves in response to air pressure changes within the acoustic enclosure. A thermally conductive structure extends over at least a portion of the passive radiator. The structure is coupled via a low thermal resistance thermally conductive path to one or more heat sources located within or coupled to the enclosure. Air accelerated by motion of the diaphragm flows over and conducts heat away from the structure and out of the acoustic enclosure. A frame secures the passive radiator and the structure in a fixed relationship, or the passive radiator is directly affixed to the structure.

[0015]Changes in air pressure within the enclosure are caused by motion of the diaphragm of an acoustic transducer coupled to the acoustic enclosure. The air pressure variations inside the acoustic enclosure, in turn, cause the passive rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com