Reinforcement bar coupler

a technology of reinforcement bars and couplers, which is applied in the direction of couplings, manufacturing tools, mechanical instruments, etc., can solve the problems of large portion of reinforcement bars lost, increased working time, and easy detachment of reinforcement bars, so as to increase the diameter of the clamping spring, easy connection, and increase the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

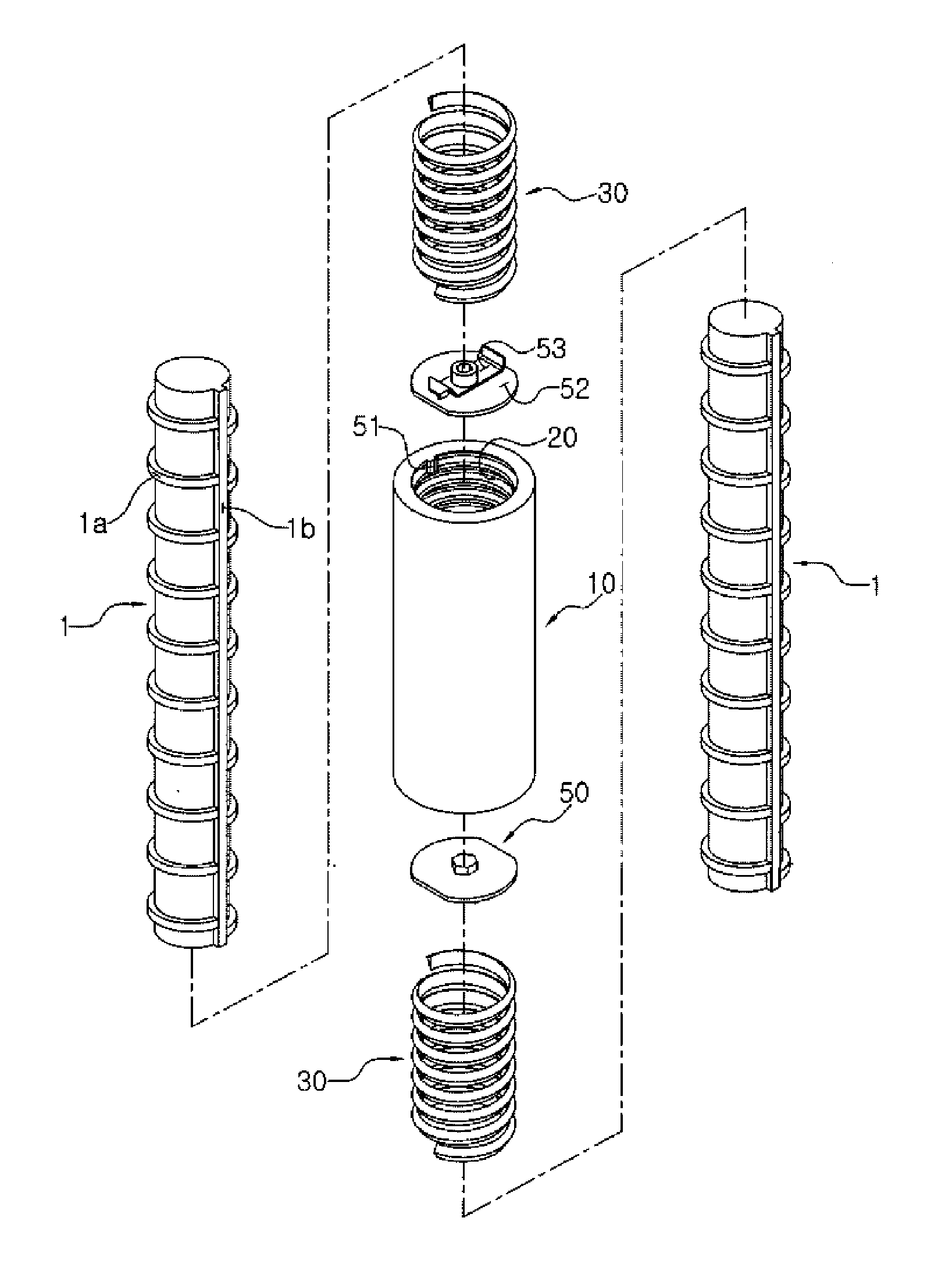

[0031]Referring to the figures, the reinforcement bar coupler according to the present invention includes a coupler cap 10, female threads 20, a clamping spring 30 and one-touch connecting means 50.

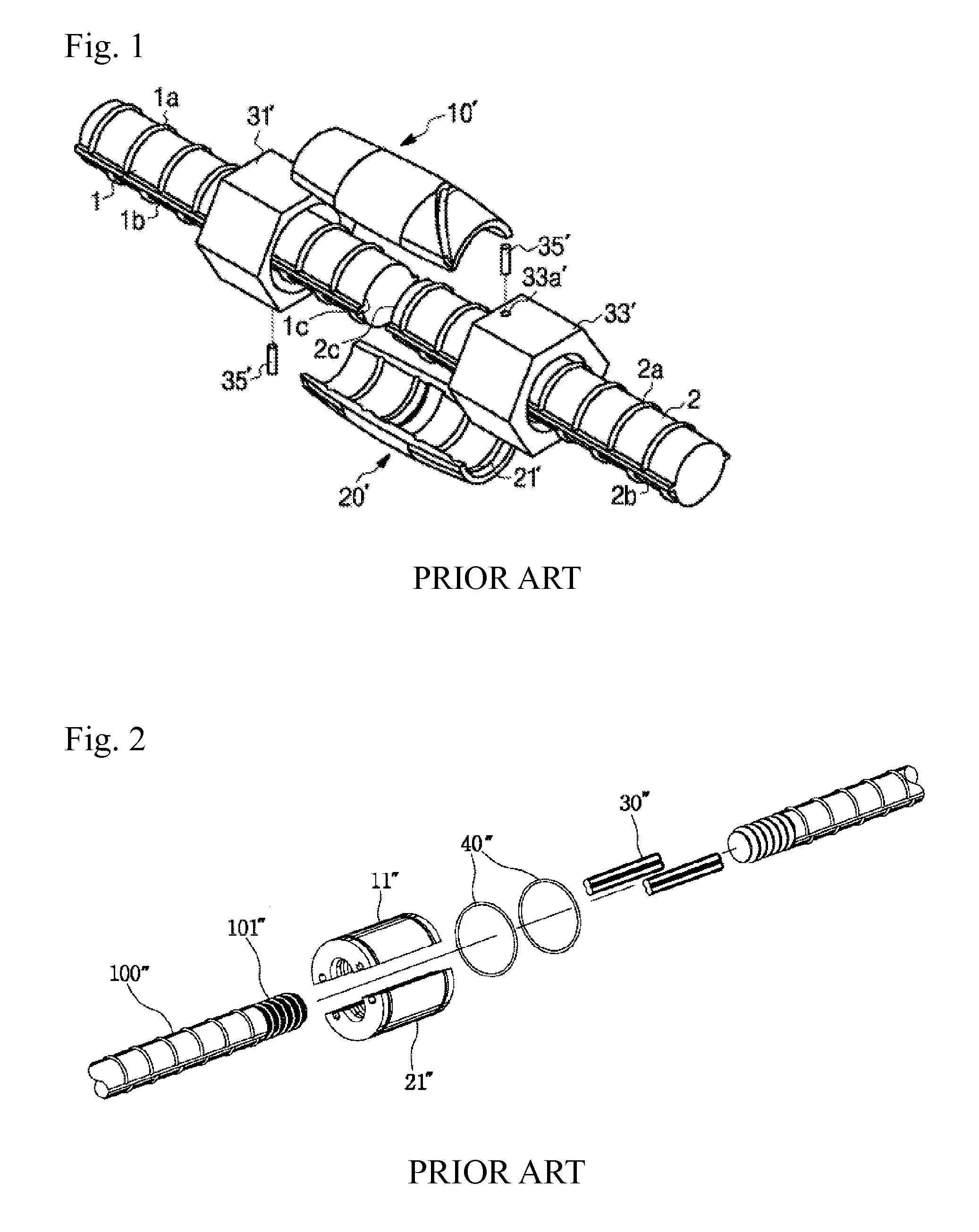

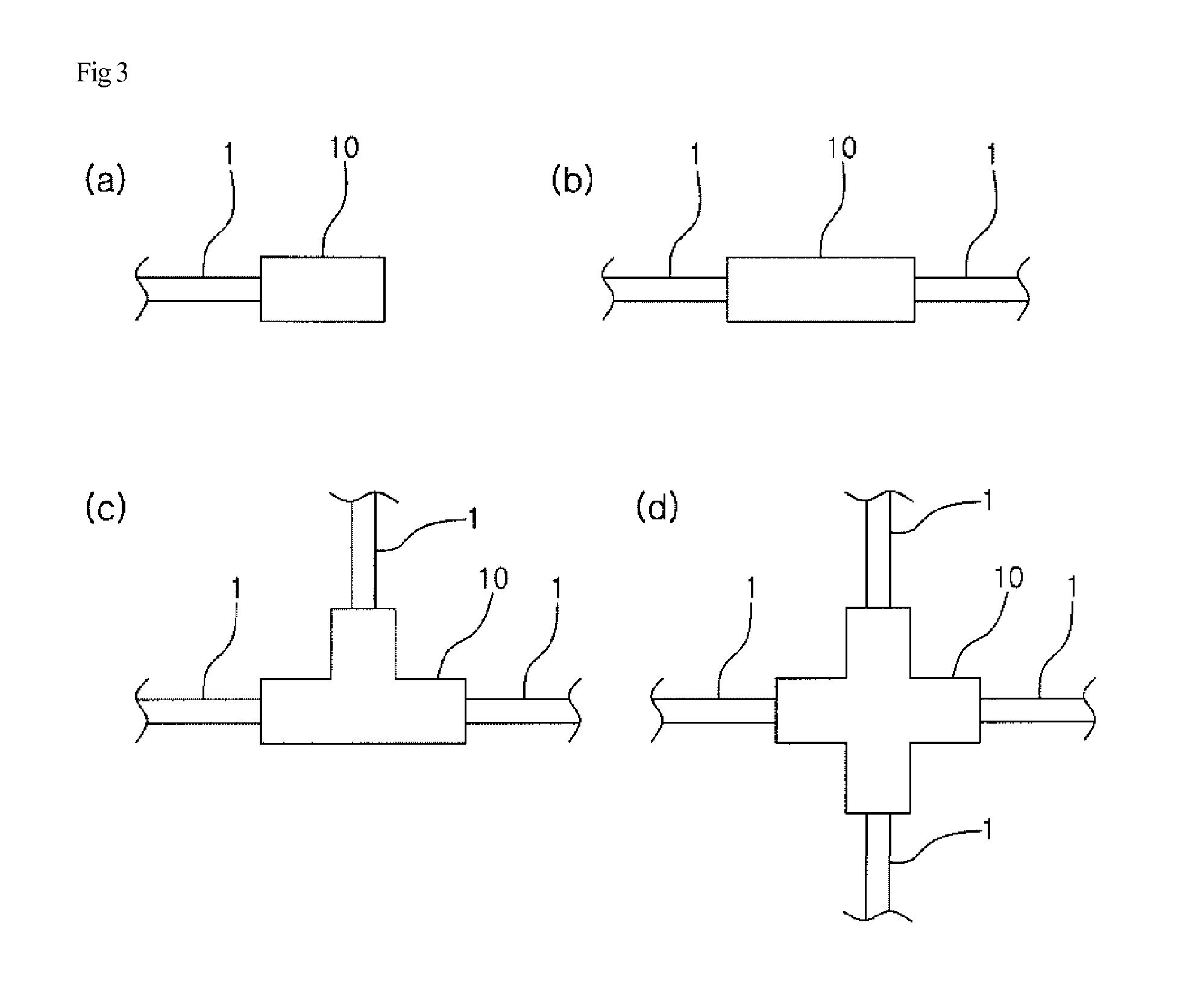

[0032]The coupler cap 10 is configured such that the reinforcement bars 1 which are to be connected and fixed to each other are inserted into the coupler cap 10 through the open outer ends. As shown in FIG. 3, the coupler cap 10 may have a variety of shapes, such as (a) an anchor type, (b) a linear type, (c) a T type, (d) a cross type, and so on.

[0033]As shown in the figures, each of the reinforcement bars 1 which are referred to herein may include a reinforcement bar having a typical shape in which the joint protrusions 1a and the rib protrusions 1b are formed, as well as a bolt having a male thread on the outer circumference thereof and a bar type member having a predetermined length.

[0034]According to the first embodiment of the present invention, the coupler cap 10 is illustrated as a...

second embodiment

[0043]The one-touch connecting means 50 prevent the clamping springs 30 from interfering with the insertion of the reinforcement bars 1 in the process in which the reinforcement bars 1 are being inserted into the coupler cap 10. When the insertion of the reinforcement bars 1 into the coupler cap 10 is completed, the one-touch connecting means 50 allow the clamping spring 30 to hold the reinforcement bars 1. Each of the one-touch connecting means 50 includes a hook portion 51, a support plate 52 and a leaf spring 53. A detailed description thereof will be given with respect to the present invention which will be described later.

[0044]The reinforcement bar coupler according to the first embodiment of the present invention has been described hereinabove, and a detailed description will be given below of a reinforcement bar coupler according to the second embodiment of the present invention.

[0045]FIG. 6 is an exploded perspective view showing the reinforcement bar coupler according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com