Seamless upper for footwear and method for making the same

a technology for footwear and uppers, applied in the field of shoeseamless uppers for footwear and the field of making the same, can solve the problems of insufficient air permeability, inability to meet the desired degree of flexibility and air permeability of the upper, and the above-mentioned shoe uppers having a plastic foam layer interposed therein, etc., to achieve maximum comfort, reduce assembly time, and facilitate production. efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

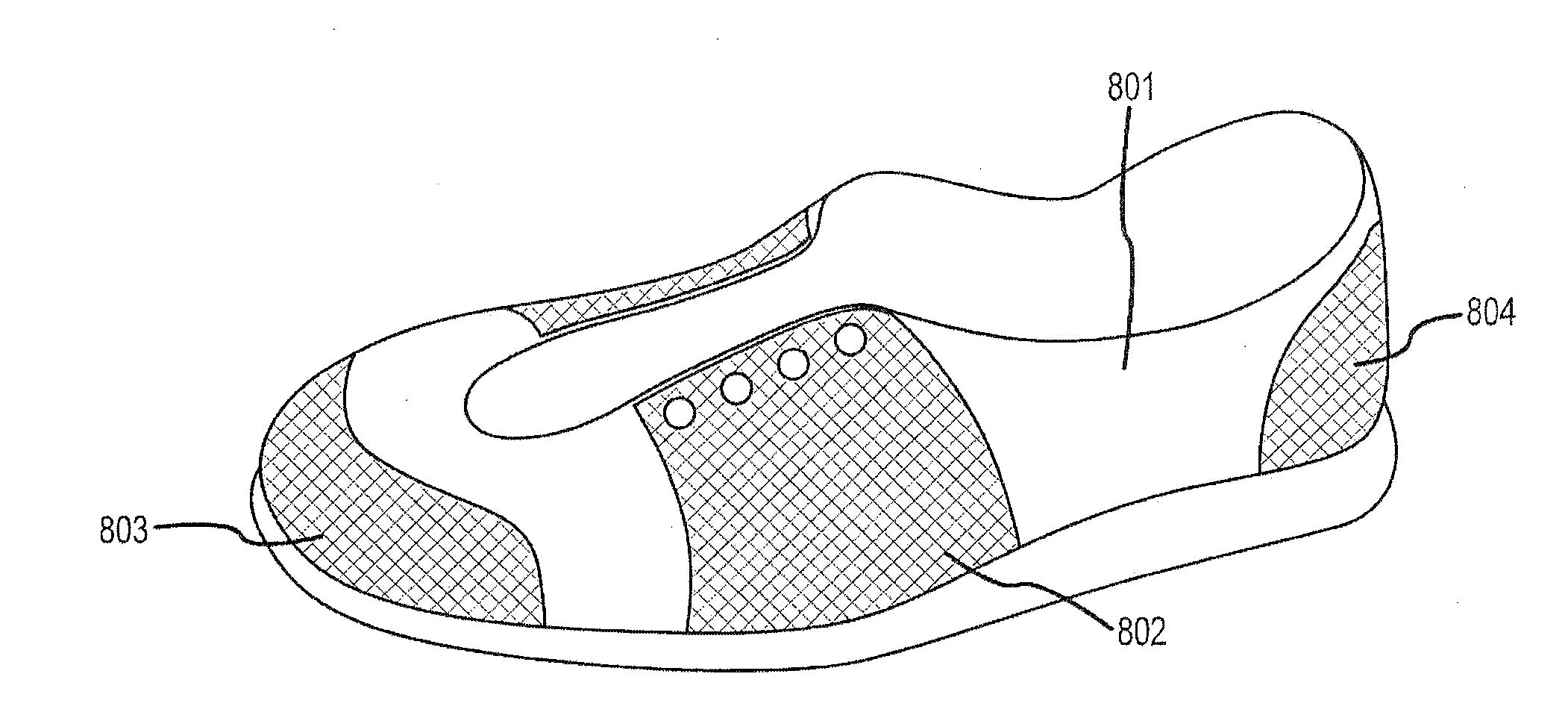

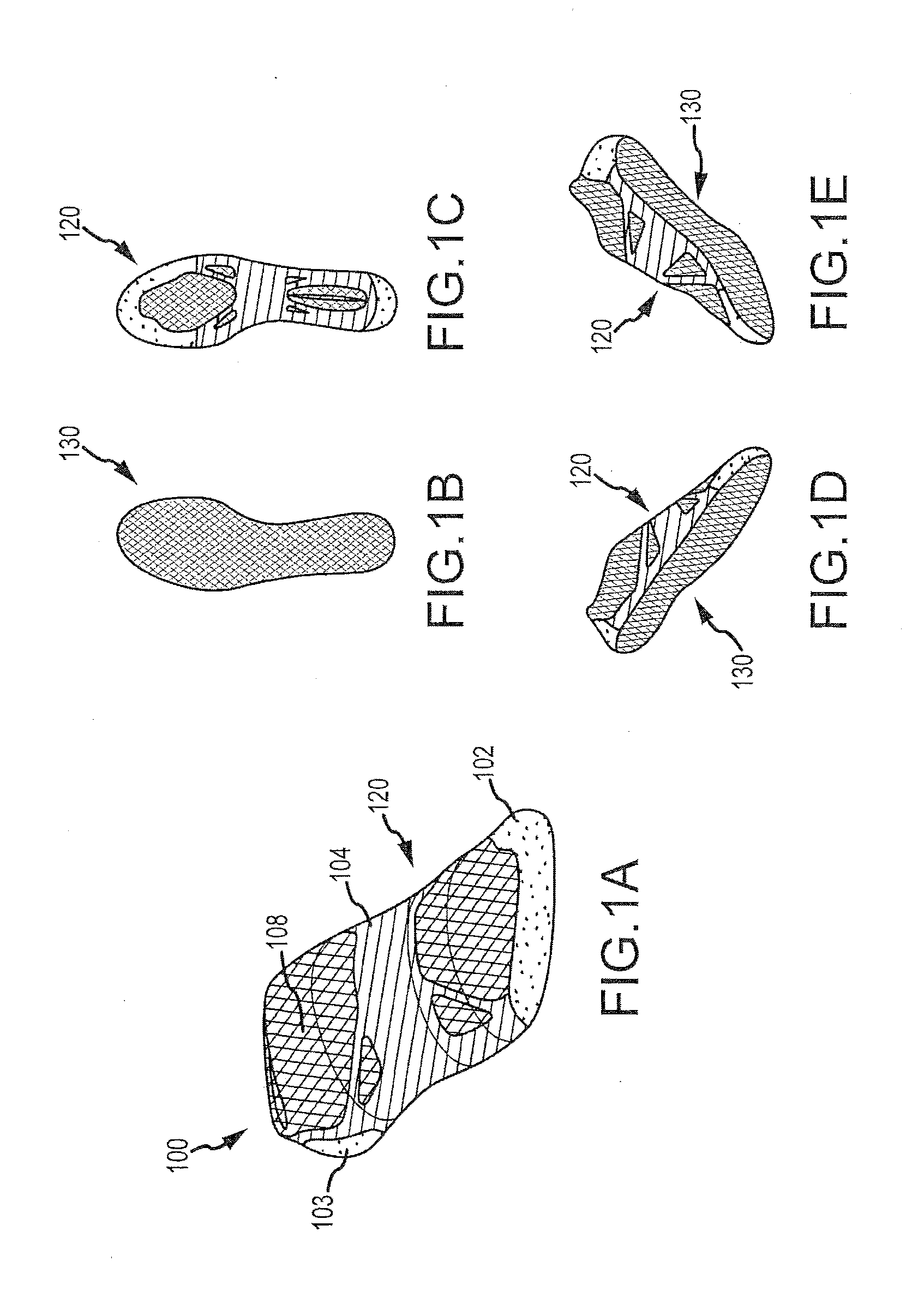

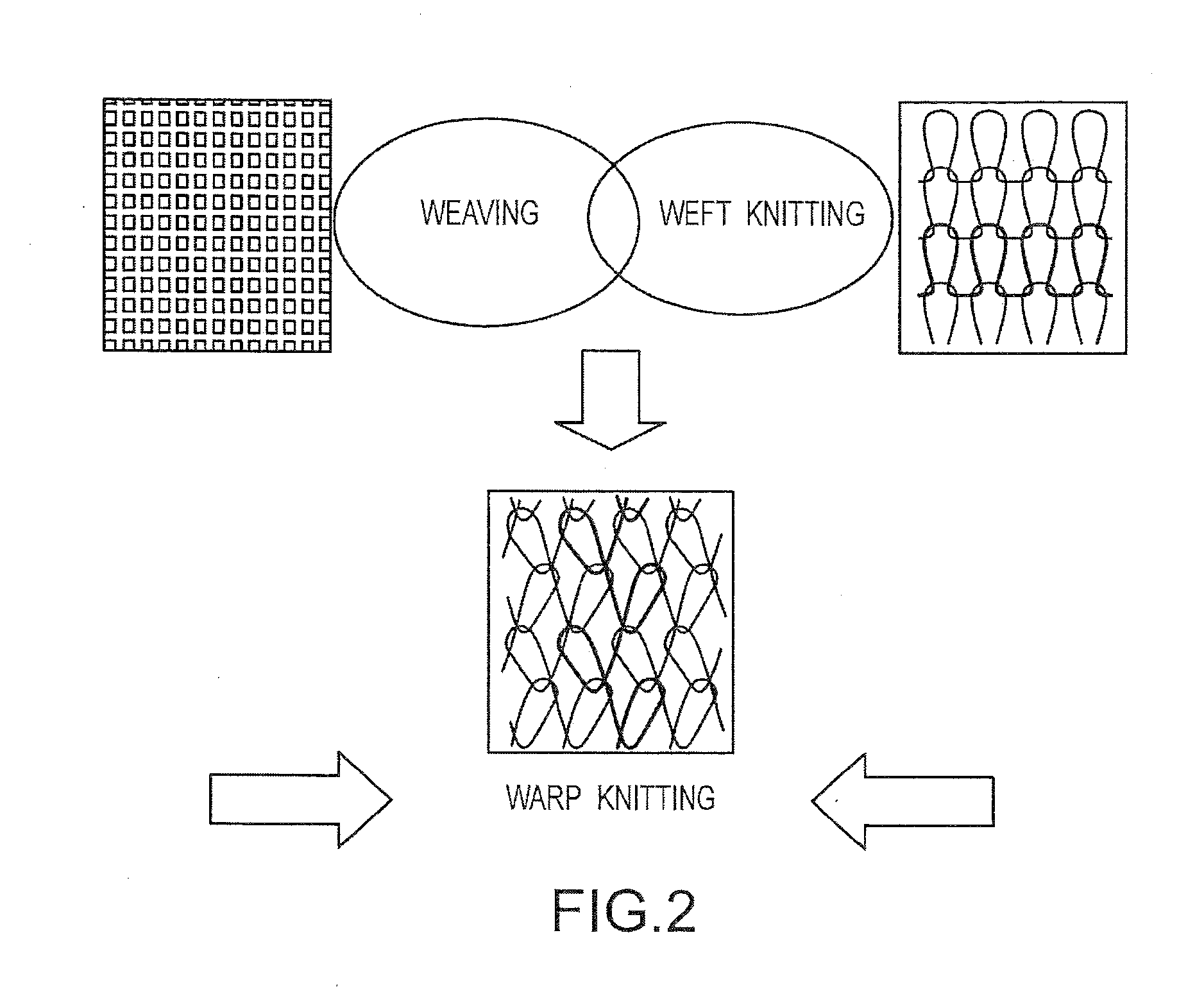

[0104]The present disclosure relates to an upper for footwear and methods for making the footwear upper. The invention involves application of a knitting process to the production of footwear uppers. In one preferred embodiment, a knitting process is disclosed to create a completely seamless upper portion of a shoe. The process can form the footwear upper in a single step. Some benefits of this process include ease and efficiency of production, reduction of assembly time, maximum comfort through reduction of seams, and freedom of design. The methods can include weaving and / or knitting the upper. The knitting process typically includes forming upper by interconnecting a series of stitches or loops.

[0105]In the following description, and for the purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the various aspects of the invention. It will be understood, however, by those skilled in the relevant arts, that the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastomeric | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com