Lateral junction assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

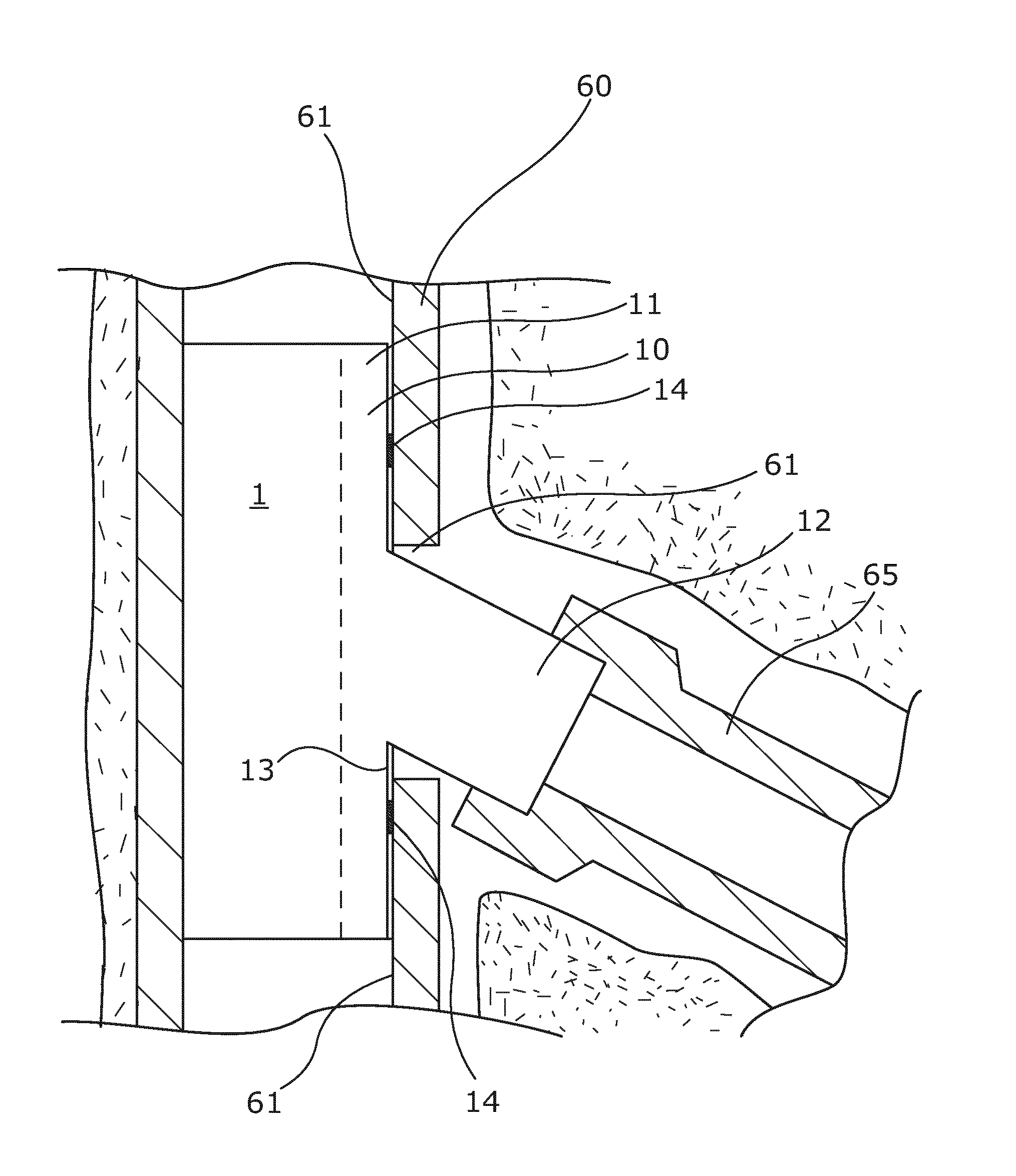

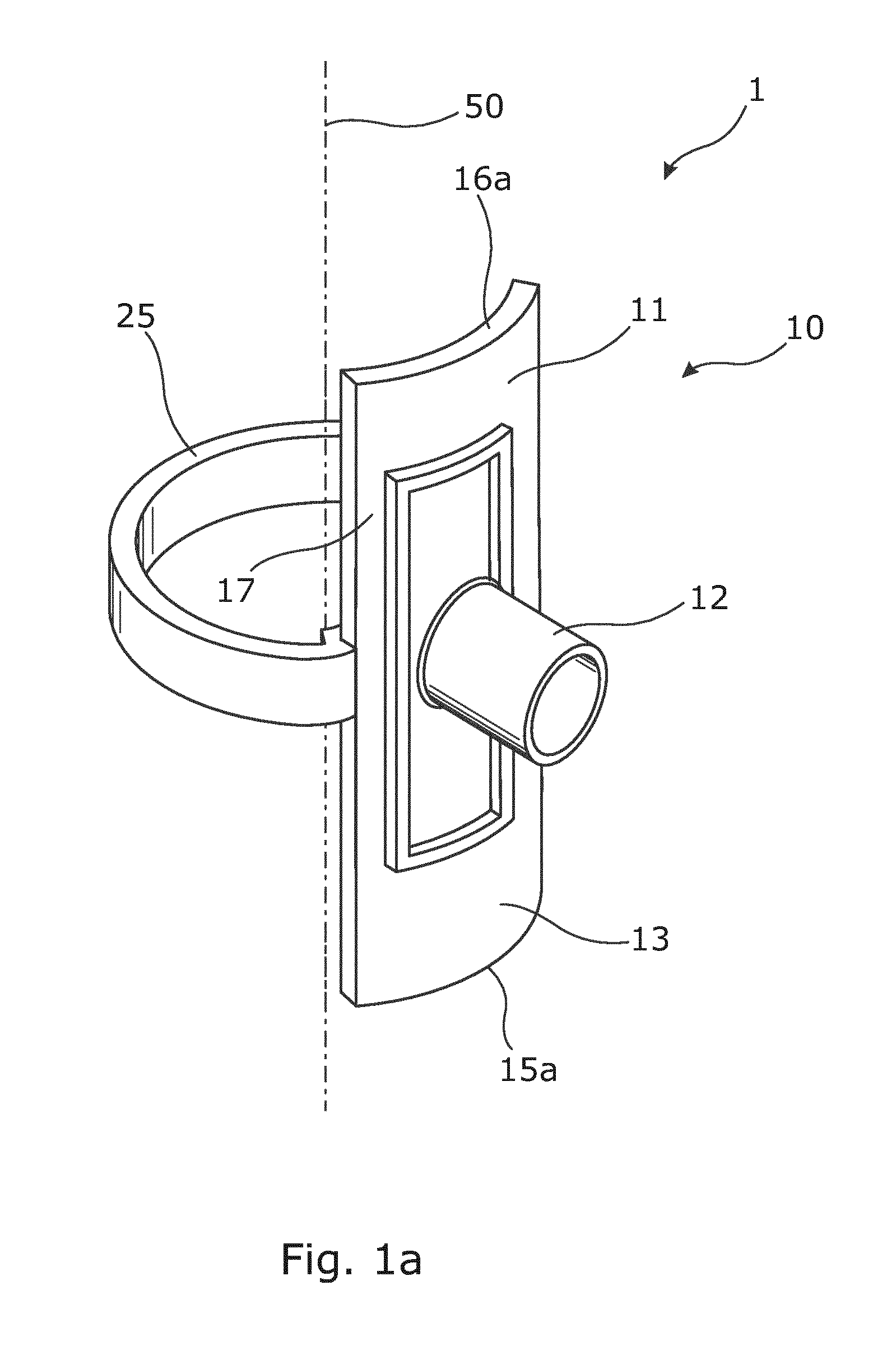

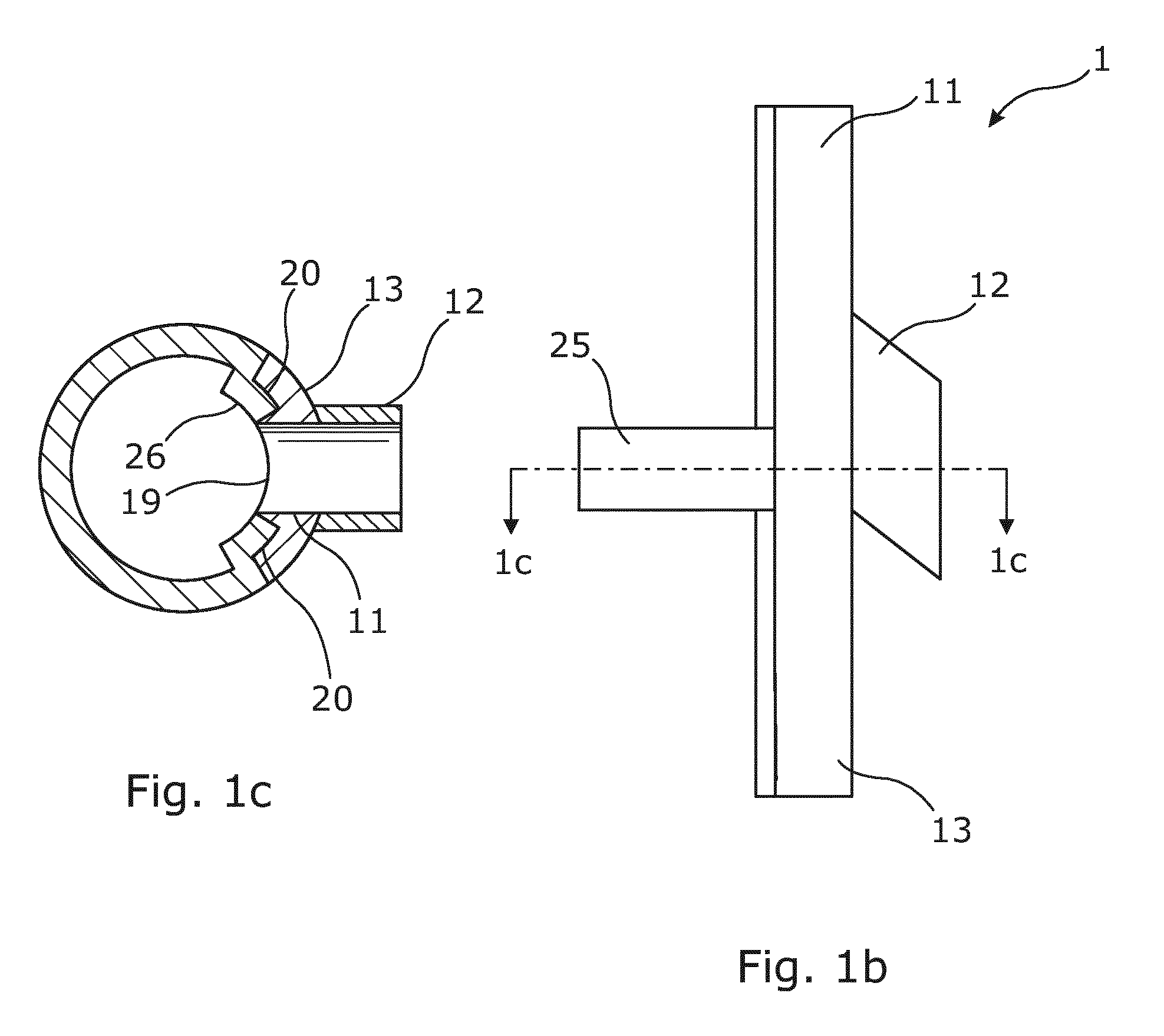

[0086]FIG. 1a shows show a lateral junction assembly 1 comprising a pipe module 10 and one fixation element 25 for fixating the pipe module 10 in a predetermined position inside a casing 60 in order to make a lateral extending from the casing 60 into the formation as shown in FIG. 6a. The lateral junction assembly 1 extends in a longitudinal direction 50 and has a top end 16a and a bottom end 15a.

[0087]The pipe module 10 comprises a flange 11 extending in the longitudinal direction 50 from a bottom edge 15a to a top edge 16a. The flange is curved in a direction transverse to the longitudinal direction 50. A pipe section 12 extends from an outer surface 13 of the flange 11 and a sealing material 14 is positioned on the outer surface 13 extending around the pipe section 12. The sealing material 14 has the shape of a strip but may be shaped and positioned in various manners that will be evident for a person skilled in the art. The pipe module further comprises a passage 18 extending f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com