Web member cutting apparatus for cutting web member that has a plurality of fibers including tows and web member cutting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

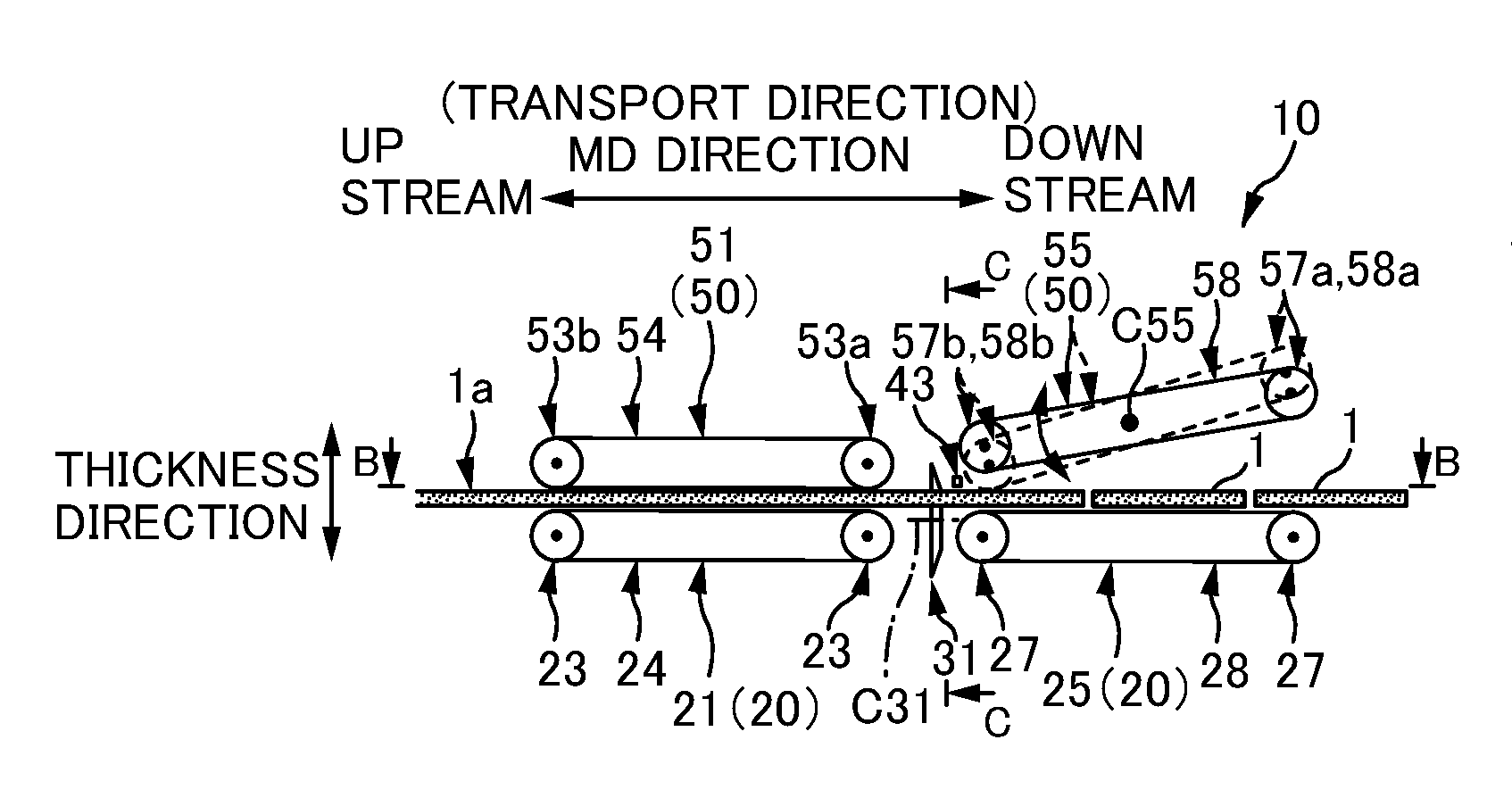

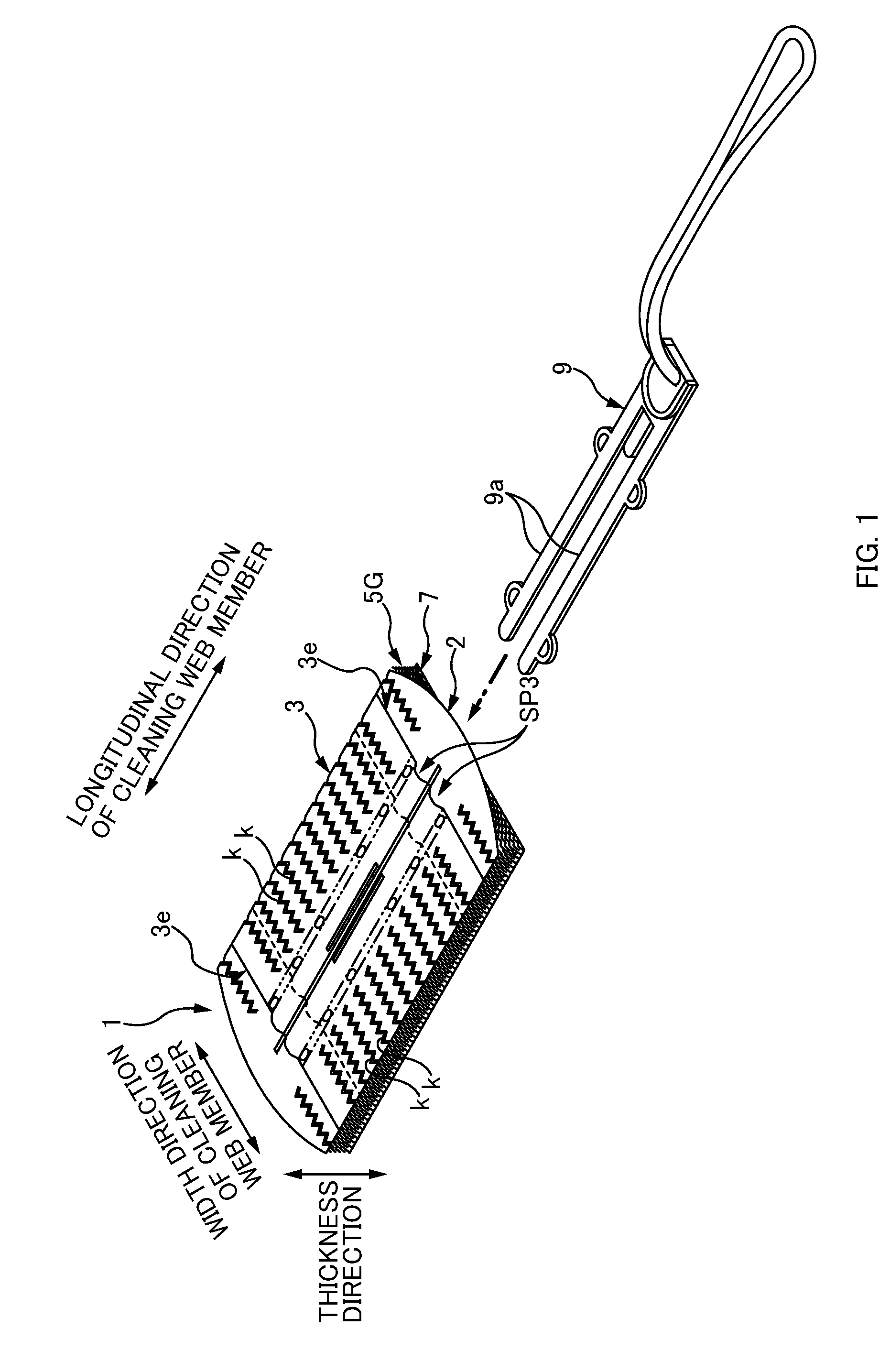

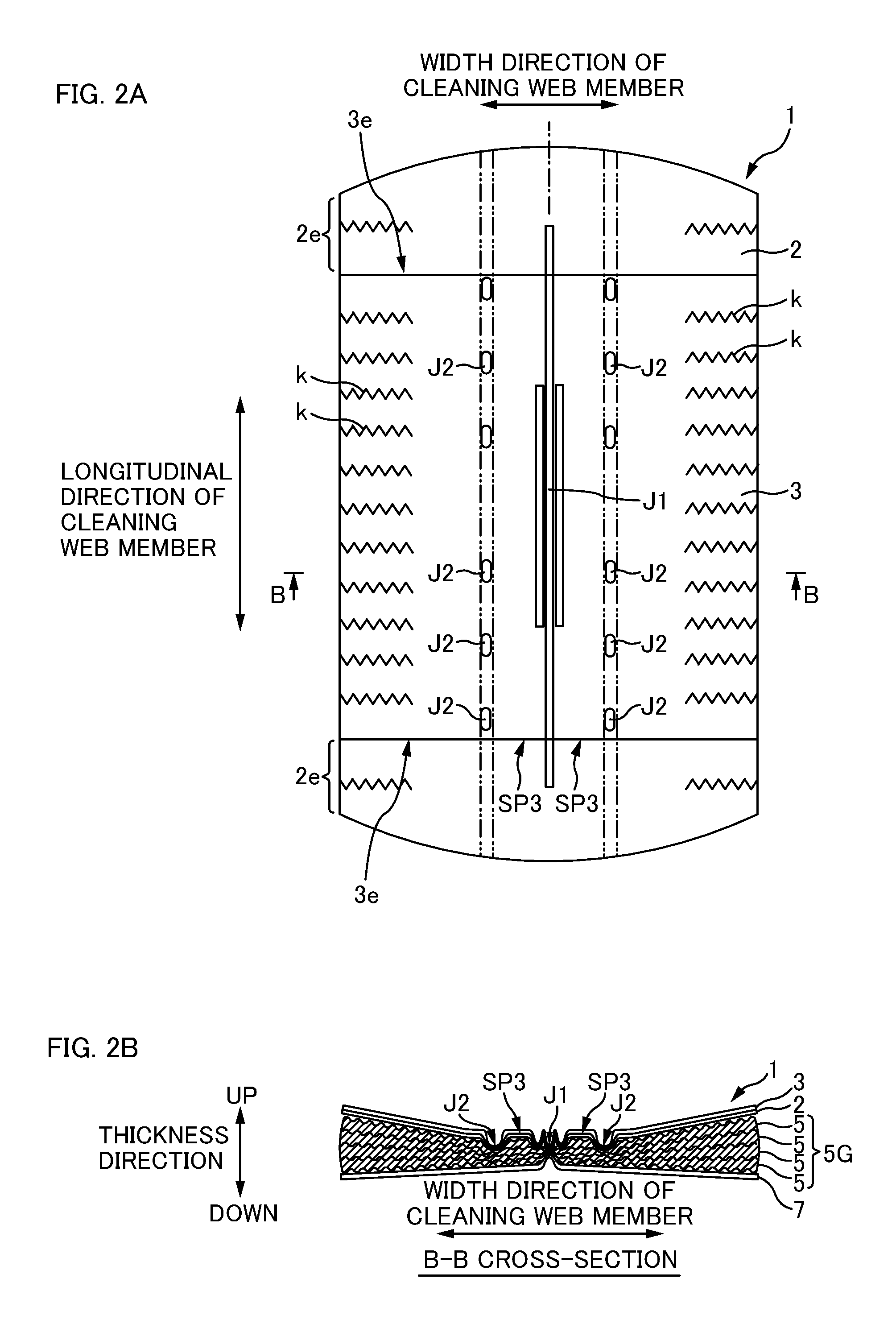

[0105]FIG. 1 is a perspective view of a cleaning web member 1 formed by cutting using a cutting apparatus 10 of the first embodiment. FIG. 2A is a plan view thereof, and FIG. 2B is a cross-sectional view taken along line B-B in FIG. 2A.

[0106]As shown in FIGS. 1 and 2A, the cleaning web member 1 (corresponding to a cut sheet-like product) is substantially in the shape of a rectangle having a longitudinal direction and a width direction when viewed from above. Furthermore, as shown in FIGS. 1 and 2B, in the thickness direction, the cleaning web member 1 includes: a base sheet 2; an auxiliary sheet 3 that covers the top surface of the base sheet 2, a fiber bundle member 5G that covers the bottom surface of the base sheet 2 and forms a main brush section, and a strip sheet 7 that is placed on the bottom surface of the fiber bundle member 5G and forms an auxiliary brush section. Here, hollows SP3 and SP3 into which a handle member 9 is inserted and secured are formed between the auxiliar...

second embodiment

[0164]FIG. 10A is a schematic side view of a cutting apparatus 10a of a second embodiment, FIG. 10B is a view along arrows B-B in FIG. 10A, and FIG. 10C is a view along arrows C-C in FIG. 10A.

[0165]The second embodiment is different from the first embodiment mainly in that the movement direction of the rotatable blade 31 in the cutting apparatus 10a is not along the CD direction but along the thickness direction of the semi-finished product 1a (corresponding to an intersecting direction). Portions other than the above are substantially similar to those in the first embodiment. Accordingly, in the description below, the same sign is used for the same configurations as the first embodiment, and description thereof is omitted.

[0166]During a transport suspension of the semi-finished product 1a, the rotatable blade 31 in the cutting apparatus 10a moves from the one side to the other side in the thickness direction of the semi-finished product 1a or moves from the other side to the one si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com