Rigid substrate, touch panel, and processing method of rigid substrate

a processing method and substrate technology, applied in the direction of static indicating devices, instruments, transportation and packaging, etc., can solve the problems of increased possibility of damage to panel devices due to lack of mechanical strength, and different sizes becoming stress concentration areas, etc., to achieve ideal mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

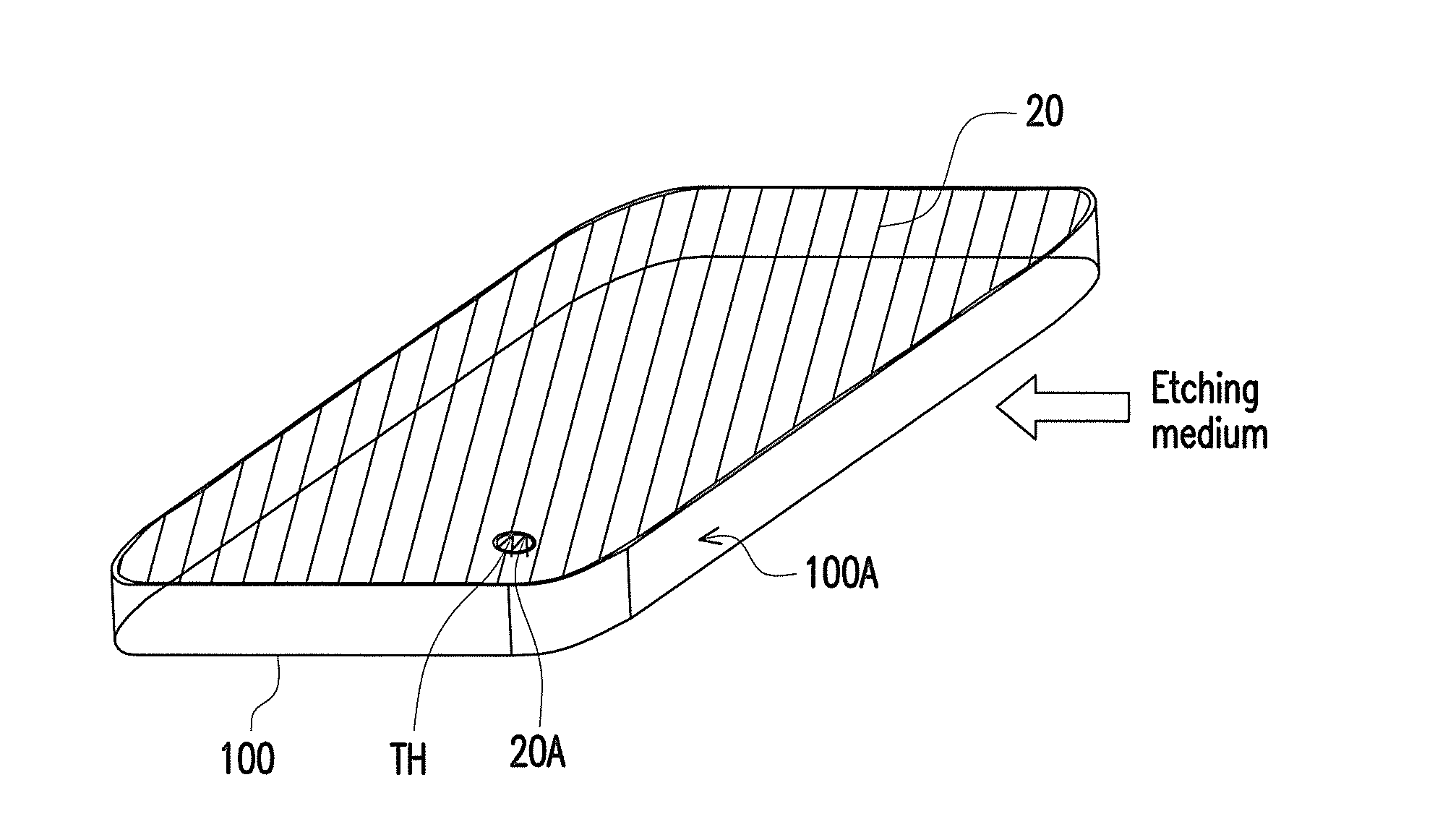

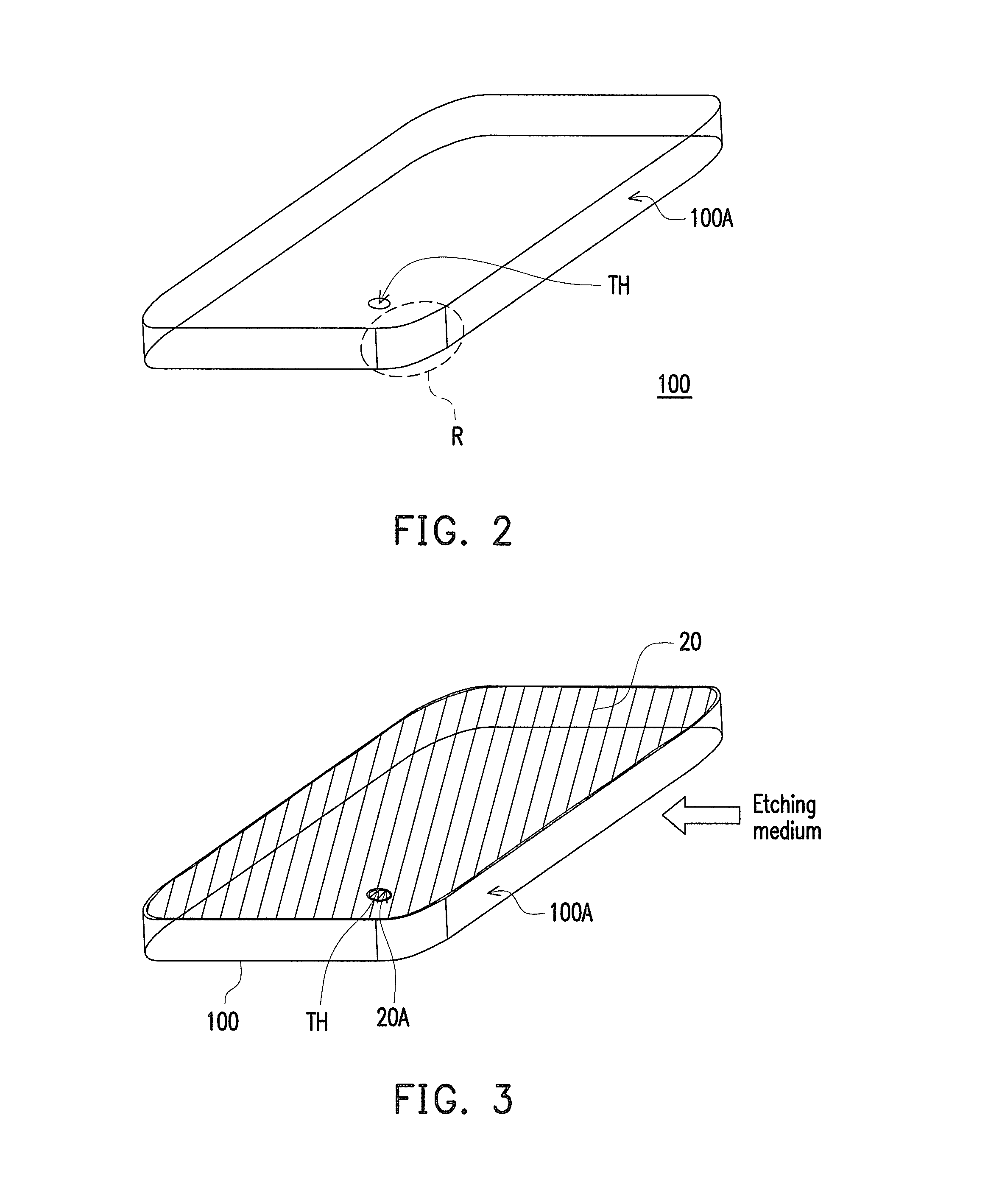

Method used

Image

Examples

Embodiment Construction

[0033]It is noted that a depth of an ion strengthened surface layer of a glass in embodiment of the invention is referring to an average depth of potassium ions diffusing from the outer surface into the interior of the glass, and a better definition is referring to an average value of maximum diffusion depths of the potassium ion when a plurality of areas are divided out on the entire outer surface of the glass. The depth of the ion strengthened surface layer generally may be obtained by utilizing an instrument to detect whether the potassium ions are present. Since even under a same manufacturing process the diffusion depths of the ions would still vary, the invention adopts the average value of the diffusion depths as a standard for determining the depth of the ion strengthened surface layer.

[0034]Namely, in an embodiment, the depth of the ion strengthened surface layer may be defined as a value obtained from averaging the corresponding measured depths of a plurality of measuring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| aperture sizes | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com