Three-phase super-long high-power heating pipe for oil well

A heating tube, high-power technology, applied in the shape of heating elements, wellbore/well components, and production fluids, etc., can solve the problem of inability to meet the requirements of single-phase heating, sharp drop in oil layer temperature and condensation, excessive single-phase line load, etc. problems, achieve ideal mechanical strength and physical and chemical properties, prolong heating life, and reduce physical labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

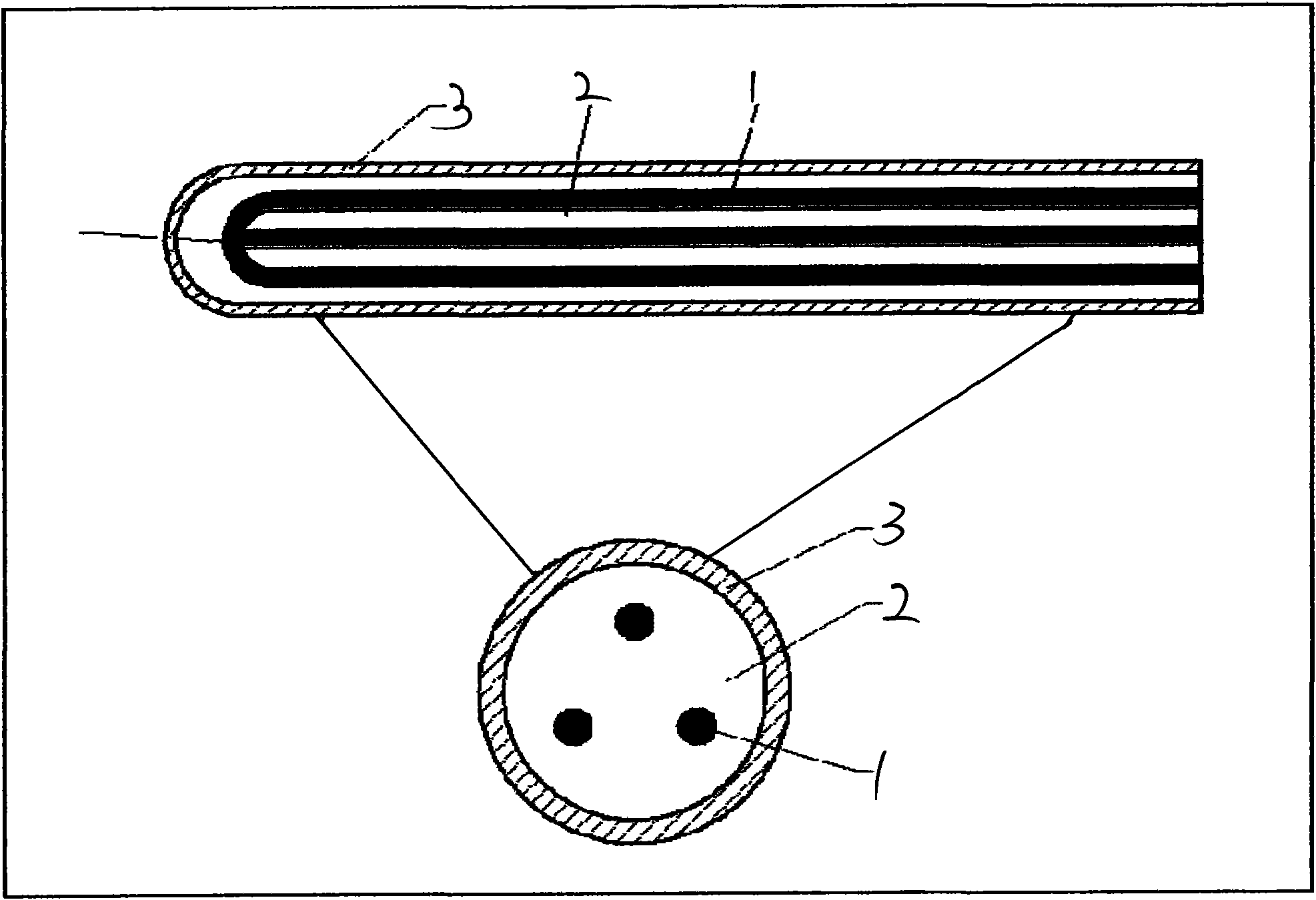

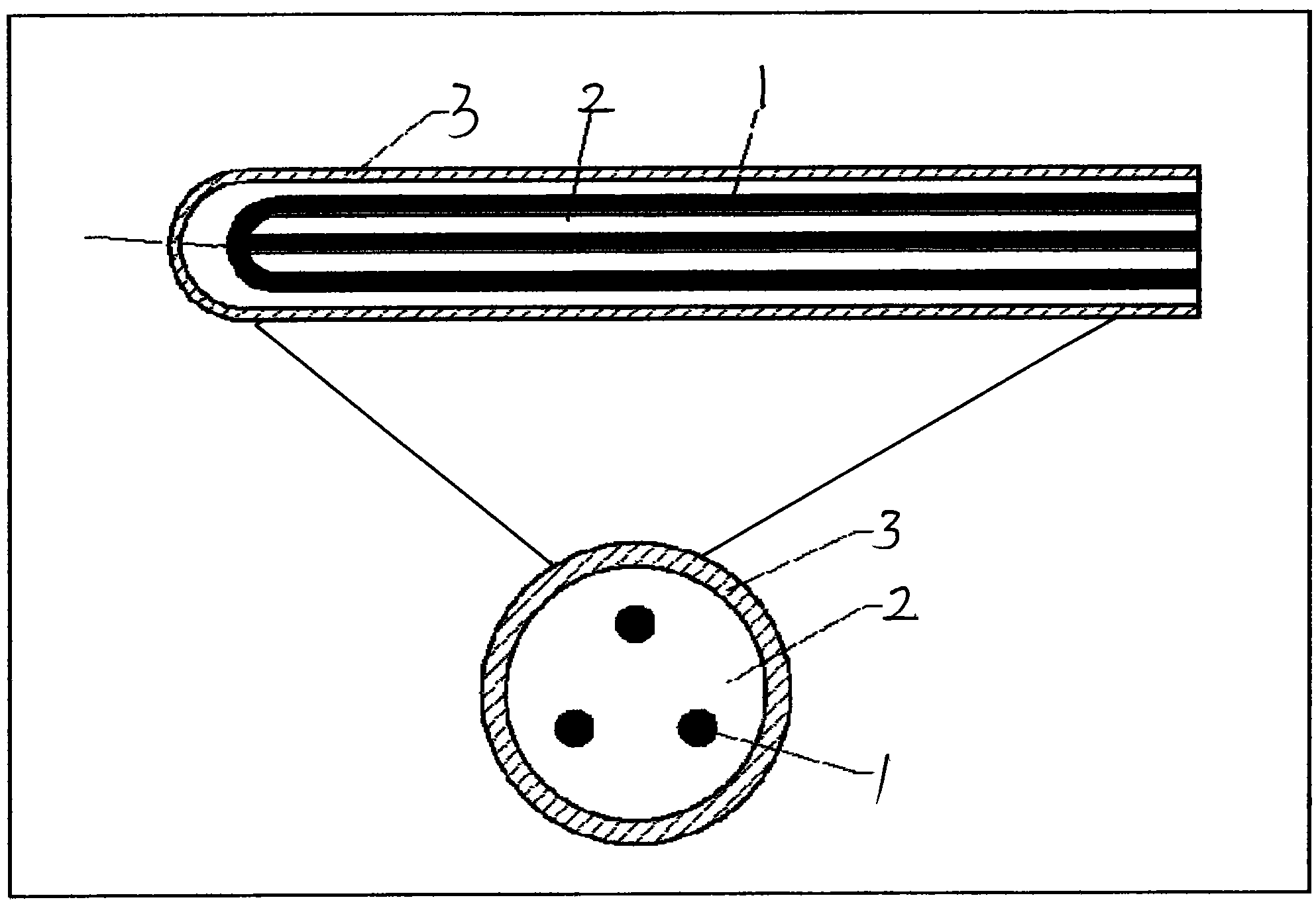

[0029] The tubular sheath is formed from the alloy strip through tube rolling and high-frequency welding. At the same time, the ceramic magnesia material is filled with special equipment and the metal wire is fixed. During the process of tube making, the wire is uniformly squeezed into the sheath. In the middle of the sheath, several rolling and shrinking processes are carried out online at the same time to make the magnesium oxide dense between the conductor and the sheath. After making a qualified three-phase super long-power heating tube semi-finished product, the calculated power and length are three The phase heating wires are Y-welded, and all of them are sealed in the magnesium oxide in the heating tube by a special process, so that a safe, reliable, super-long and complete three-phase Y-connected high-power super-long heating tube is made. The oil well three-phase super high-power heating tube is 68 meters long, the working voltage is 380V, and the power is 75KW.

Embodiment 2

[0031] The calculated heating metal conductor is inserted into the magnesium oxide core and then penetrated into the large-diameter metal tube. After repeated drawing by the tube drawing machine, the calculated power and length are made into a semi-finished product, and the calculated power and length are used for three-phase heating. The wires are Y-welded, and all of them are sealed in the magnesium oxide in the heating tube by a special process, so that a safe, reliable, super-long and complete three-phase Y-connected high-power super-long heating tube is made. The oil well three-phase super high-power heating tube is 55 meters long, the working voltage is 380V, and the power is 55KW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com