Container Wall for a Container Covered by a Film

a technology for containers and walls, applied in the field of containers, can solve the problems of film slipping out of the rail, increased effort when opening the cover, and the cover may lose its function, and achieve the effect of producing and assembling even more simply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]While this invention may be embodied in many different forms, there are described in detail herein a specific preferred embodiment of the invention. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiment illustrated.

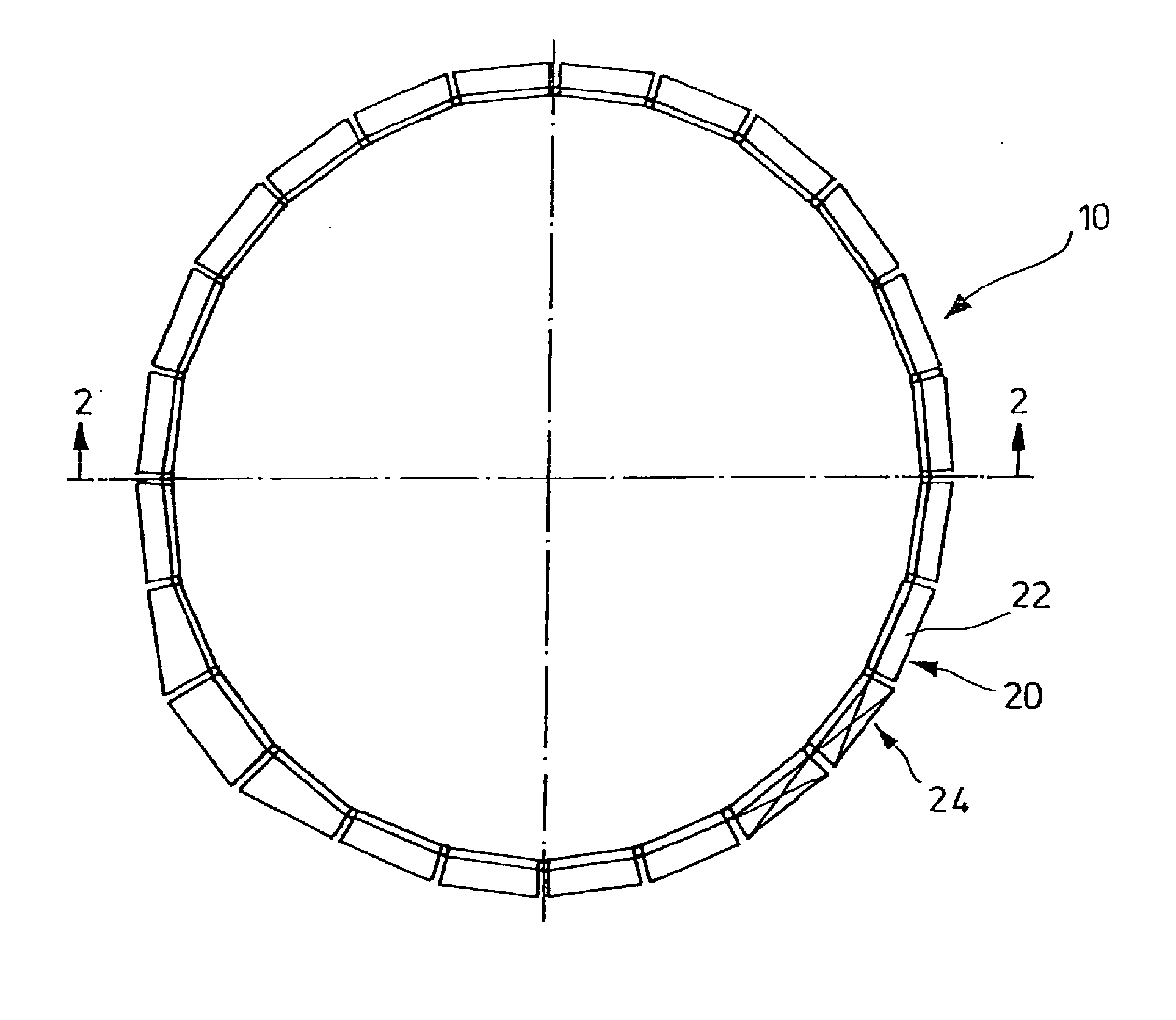

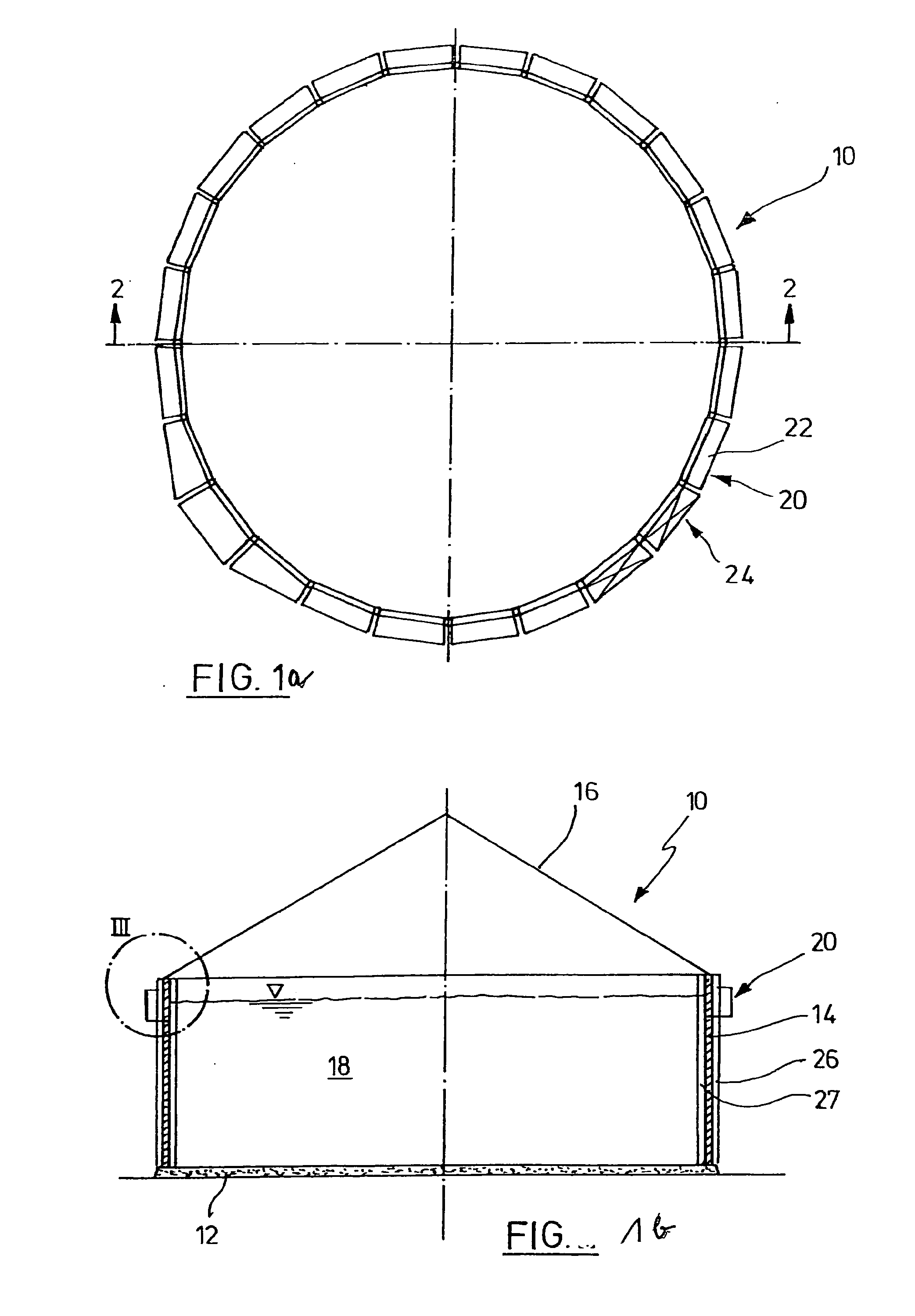

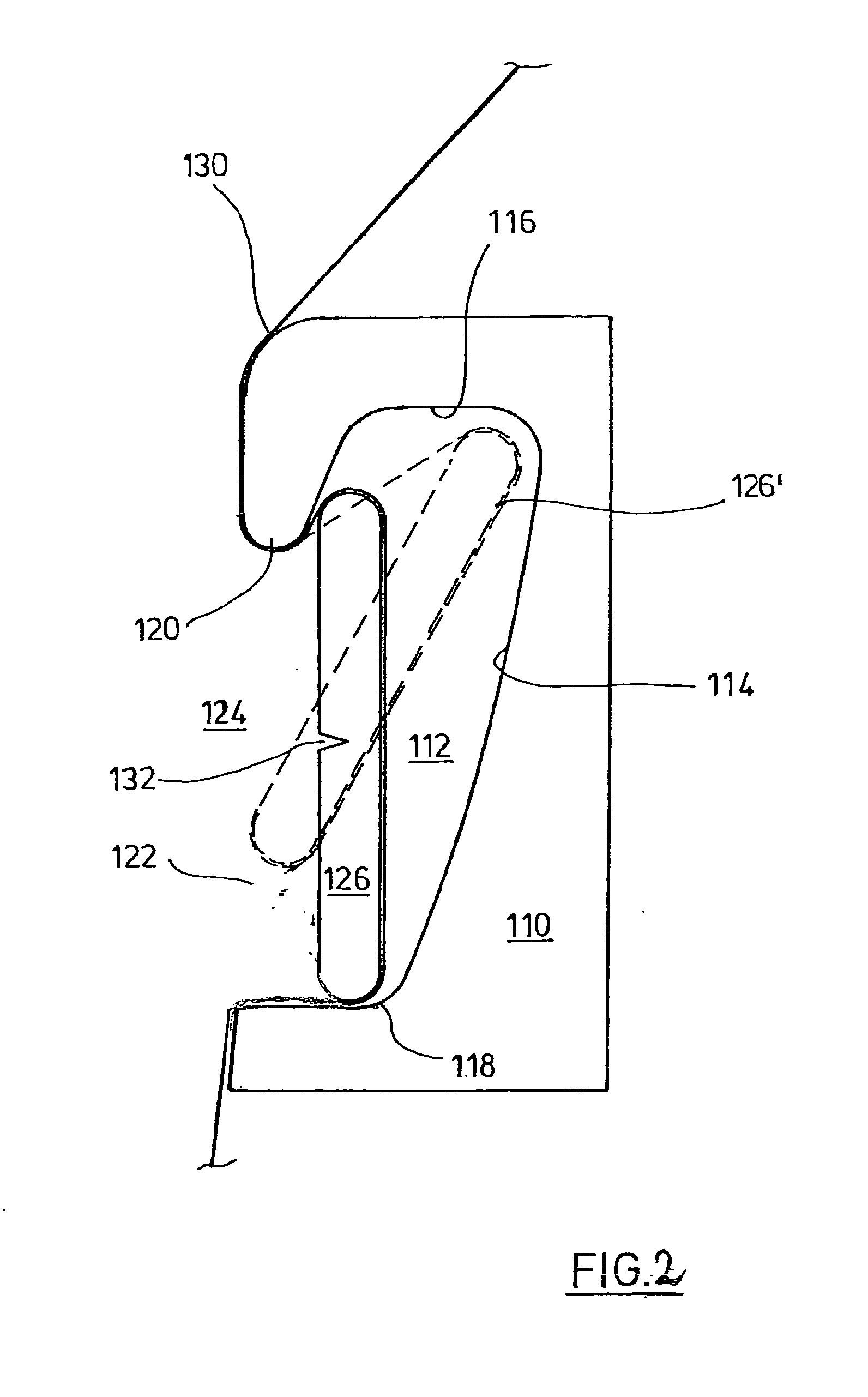

[0045]A container 10 is indicated in FIGS. 1a and b, said container comprising a base 12 made of concrete and a cylindrical wall 14, also made of concrete. The concrete wall is produced, for example, by means of a plurality of shuttering elements arranged externally and internally. At least one plastic film 16 is stretched over the top of the container 10, the edge thereof being secured in the upper region to the outer face of the wall 14, as will be described in more detail below. For example a fermenting agent 18 is located in the container. A peripheral walkway 20 with a handrail is shown on the outer face of the wall 14. The walkway consists of individual walkway elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com