Method for making a perpendicular thermally-assisted recording (TAR) magnetic recording disk having a carbon segregant

a technology of thermally assisted recording and magnetic recording disk, which is applied in the direction of magnetic recording, data recording, instruments, etc., can solve the problems of exceeding the write field capability of the write head, increasing the coercivity of the media, etc., and achieves the effect of increasing the vertical height of the grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

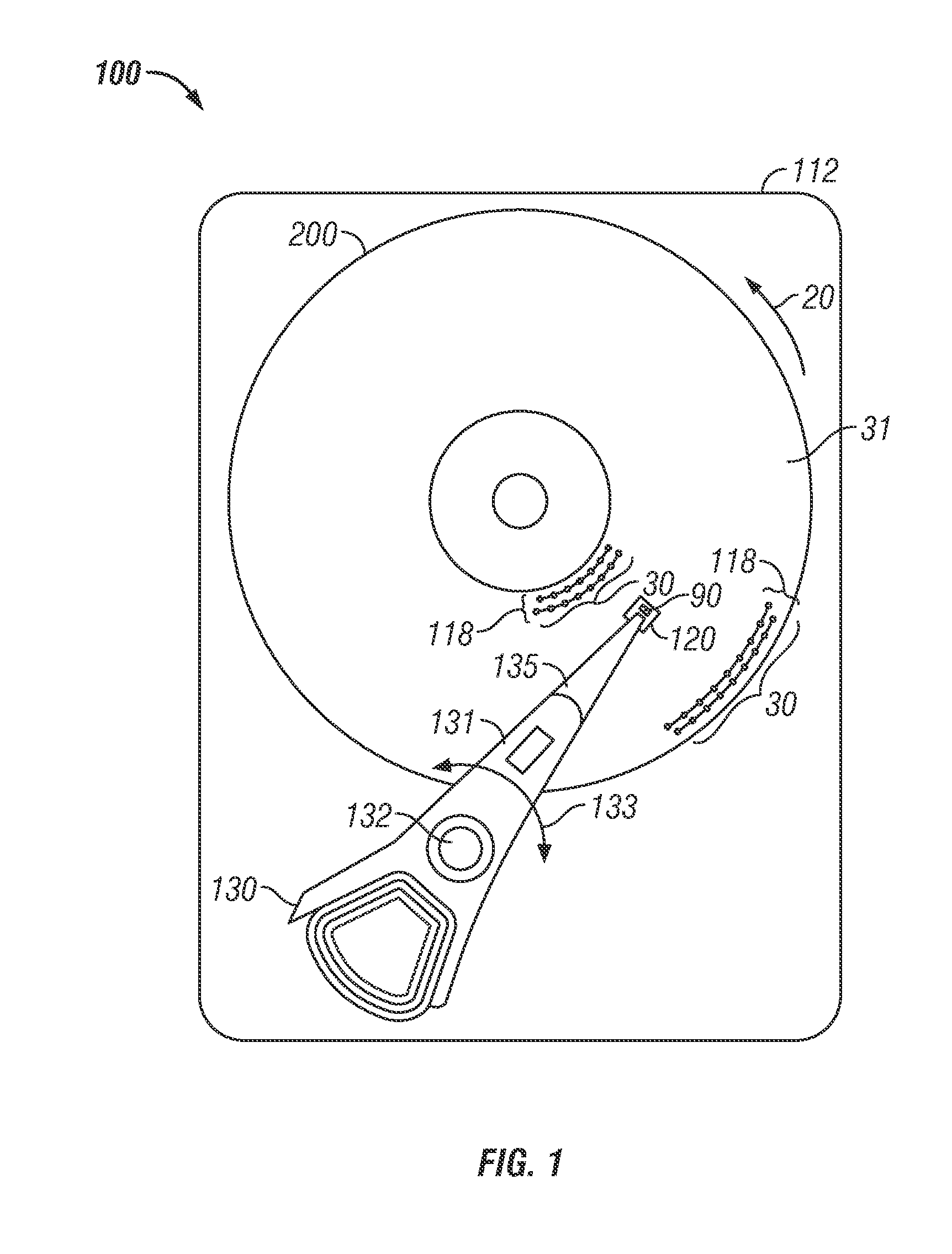

[0024]FIG. 1 is a top view of a thermally-assisted recording (TAR) disk drive 100 according to the invention. In FIG. 1, the TAR disk drive 100 is depicted with a disk 200 with magnetic the recording layer 31 patterned into discrete data islands 30 of magnetizable material arranged in radially-spaced circular tracks 118. Only a few representative islands 30 and representative tracks 118 near the inner and outer diameters of disk 200 are shown. However, instead of the bit-patterned-media (BPM) shown with discrete data islands 30 in FIG. 1, the TAR disk drive may instead use disks in which the recording layer 31 is a conventional continuous magnetic recording layer of magnetizable material.

[0025]The drive 100 has a housing or base 112 that supports an actuator 130 and a drive motor for rotating the magnetic recording disk 200. The actuator 130 may be a voice coil motor (VCM) rotary actuator that has a rigid arm 131 and rotates about pivot 132 as shown by arrow 133. A head-suspension a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com