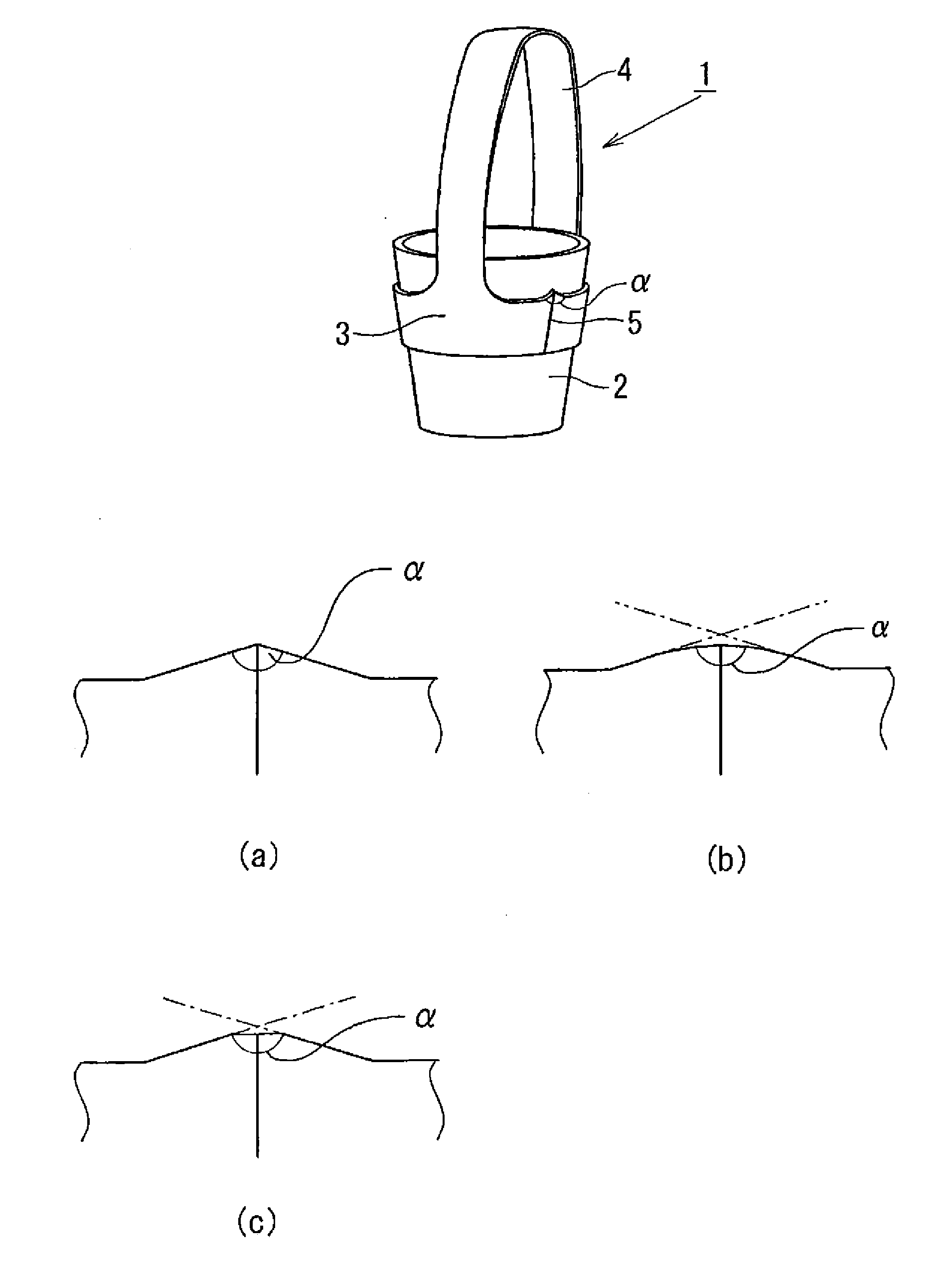

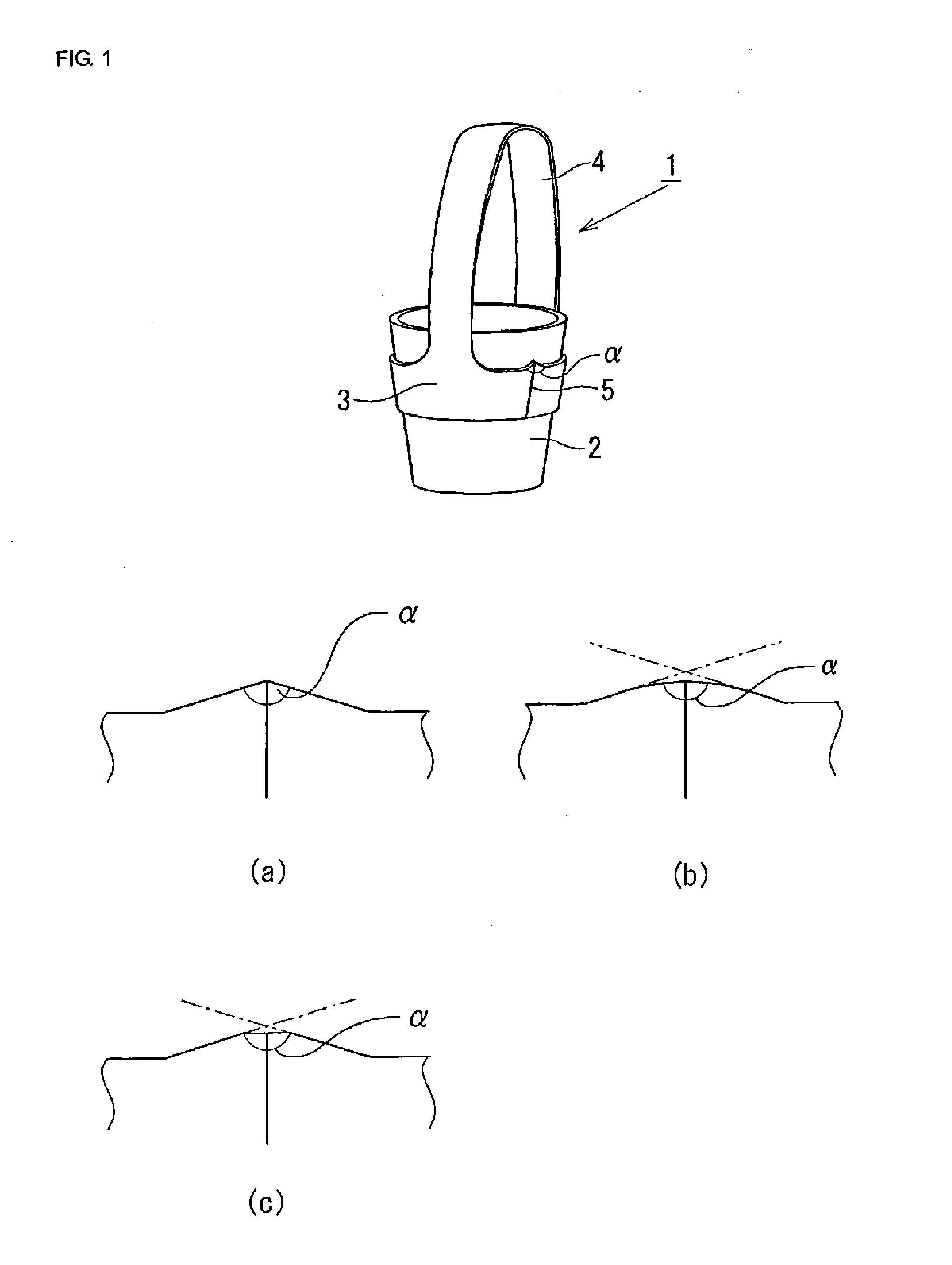

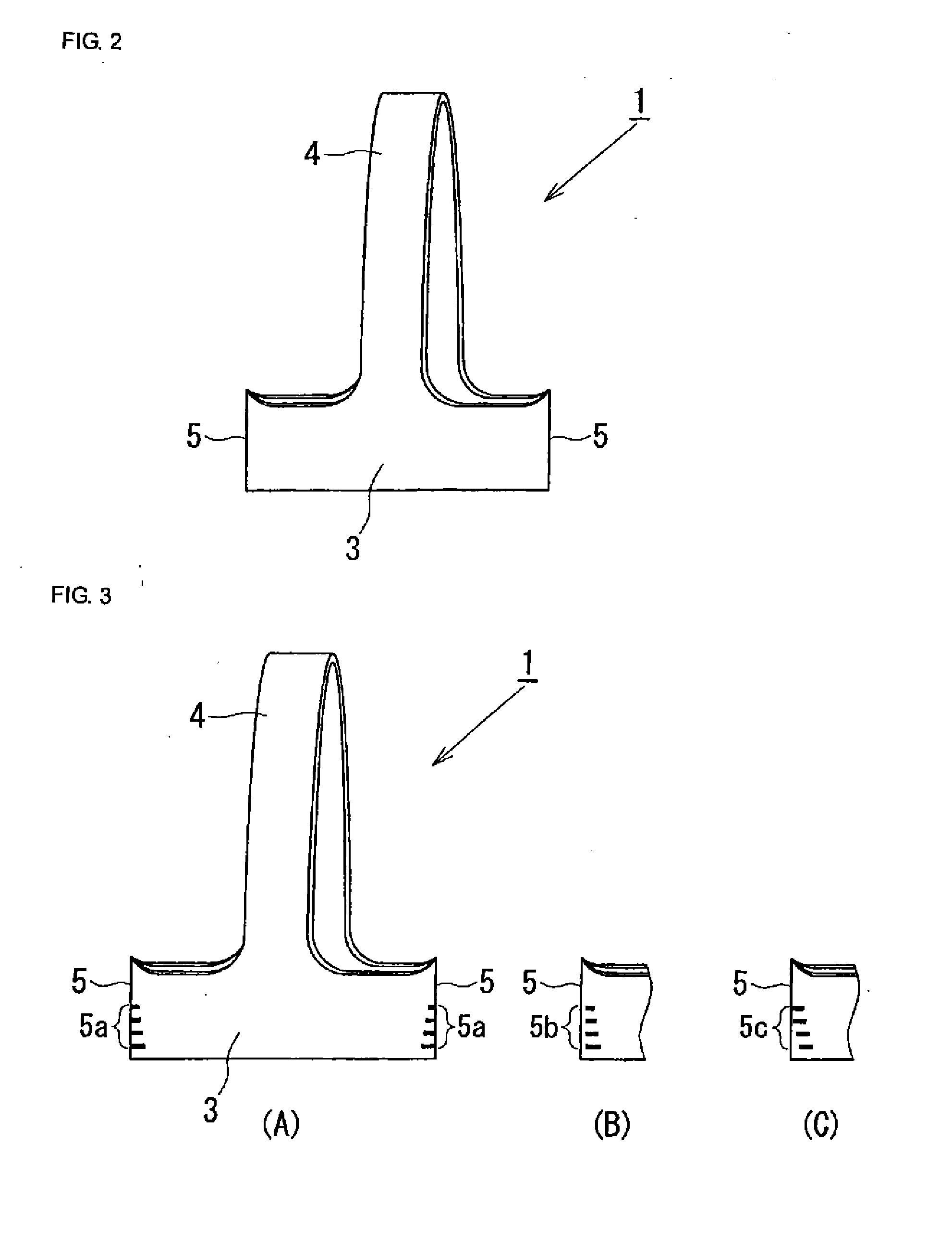

Disposable holder for beverage container

a beverage container and holder technology, applied in the field of beverage container holders, can solve the problems of reducing workability in shops, user burns, and a lot of time and labor, and achieve the effects of simple configuration, convenient use, and safe carrying of beverages in cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example

Manufacturing of Beverage Container Holder in the Form Before Use (Separation Means: Perforations)

[0096]A method for manufacturing the beverage container holder in the form before use shown in FIG. 5 will be described with reference to the process diagram of FIG. 9.

[0097]A cylindrical film 13 made of high density polyethylene and having a thickness of 30 μm (FIG. 9(a)) was heat-welded and cut along melt cut lines 19, 20 to form a basic holder pattern portion 21. Perforations 22 (6 mm-long cut portions and 1.5 mm-long non-cut portions) were formed in the basic holder pattern portion 21 with a perforation cutter, and holes 23 were formed (see FIGS. 9(b) and 9(c)).

[0098]Subsequently, the basic holder pattern 21 was cut along cut lines 24 to remove removal portions 25. Beverage container holders 6 in the form before use were thus manufactured.

[0099]As shown in, e.g., FIG. 10, the beverage container holder 6 in the form before use thus obtained had the following size.

[0100]The length 1a ...

second example

Beverage Container Holder Product (Separation Means: Perforations)

[0106]A method for manufacturing a beverage container holder product (separation means: perforations) will be described with reference to FIG. 11.

[0107]200 of the beverage container holders 6 in the form before use manufactured in the first example were stacked to form a holder bundle. In this example, a retaining member 26 was formed by a holder cover 27, a hanger 28, and fasteners 29.

[0108]A plate of high-density polyethylene having a thickness of 1 mm was used as the holder cover 27 for the beverage container holder product 10. The holder cover 27 was formed to have a front surface 27a covering 90% or more of the beverage container receiving portion 3 of the beverage container holder 1 and having holes 27d, 27e (hole diameter: 5 mm, located 7.5 mm away from the upper end, and distance between the holes: 9 cm) at positions corresponding to the holes 9 of the holder, a spine portion 27b formed continuously with the f...

third example

Disposable Beverage Container Holder

[0113]One of the holders bundled in the beverage container holder product (separation means: perforations) manufactured in the second example was separated along the perforations by pulling to obtain a disposable beverage container holder.

[0114]In the disposable beverage container holder thus obtained, a beverage container, which was a coffee cup with a lid, was able to be easily placed and held in the cylindrical beverage container receiving portion of the holder. The disposable beverage container holder holding the beverage container was convenient to hold with a hand or to hang over the hand, and no coffee spilled from the cup. The handle portion and the beverage container receiving portion had enough strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com