Image transfer process employing a hard mask layer

a technology of image transfer and mask layer, which is applied in the direction of instruments, transportation and packaging, printing, etc., can solve the problems of pattern transfer fidelity degradation, and achieve the effect of high-fidelity pattern transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

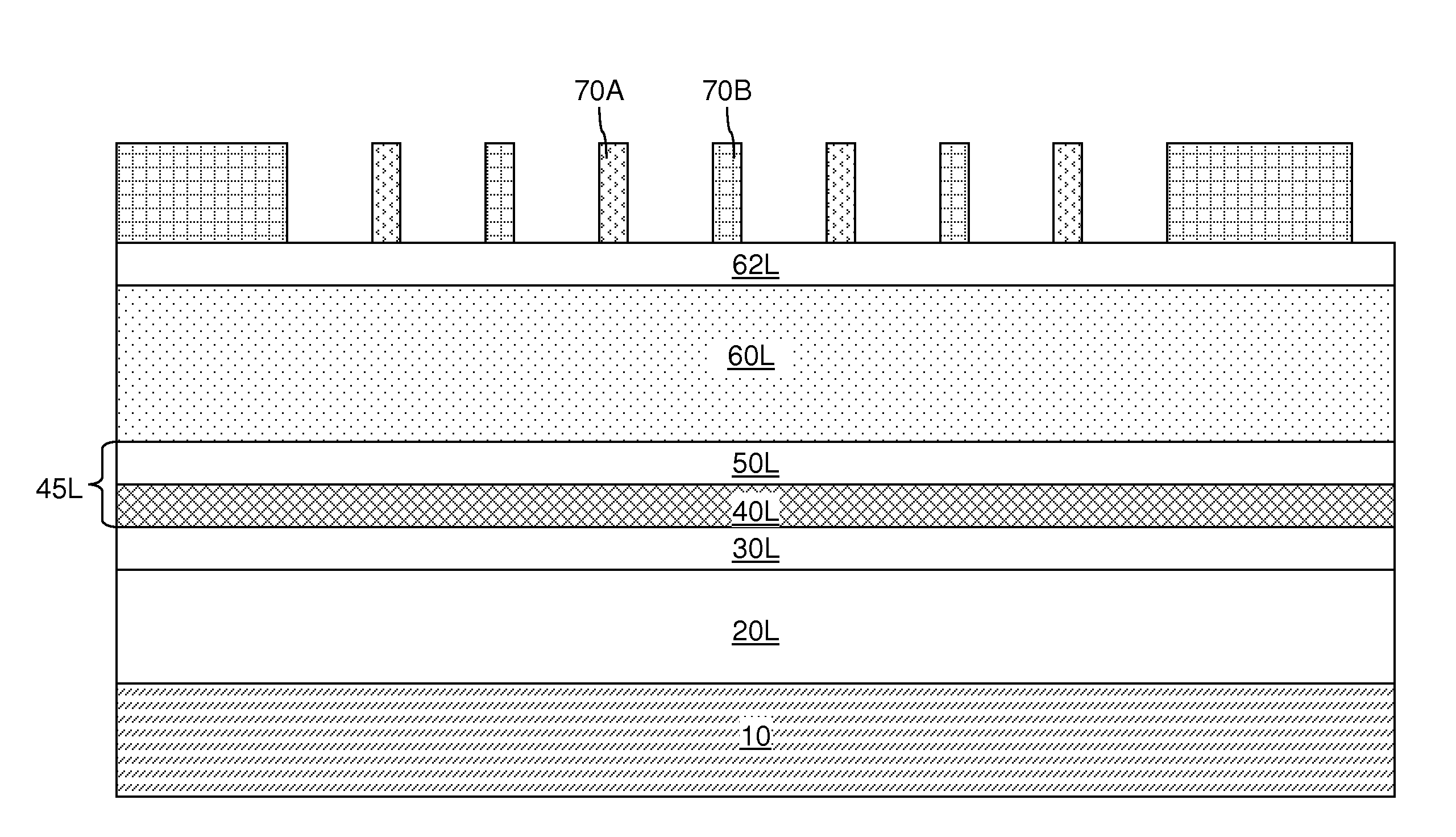

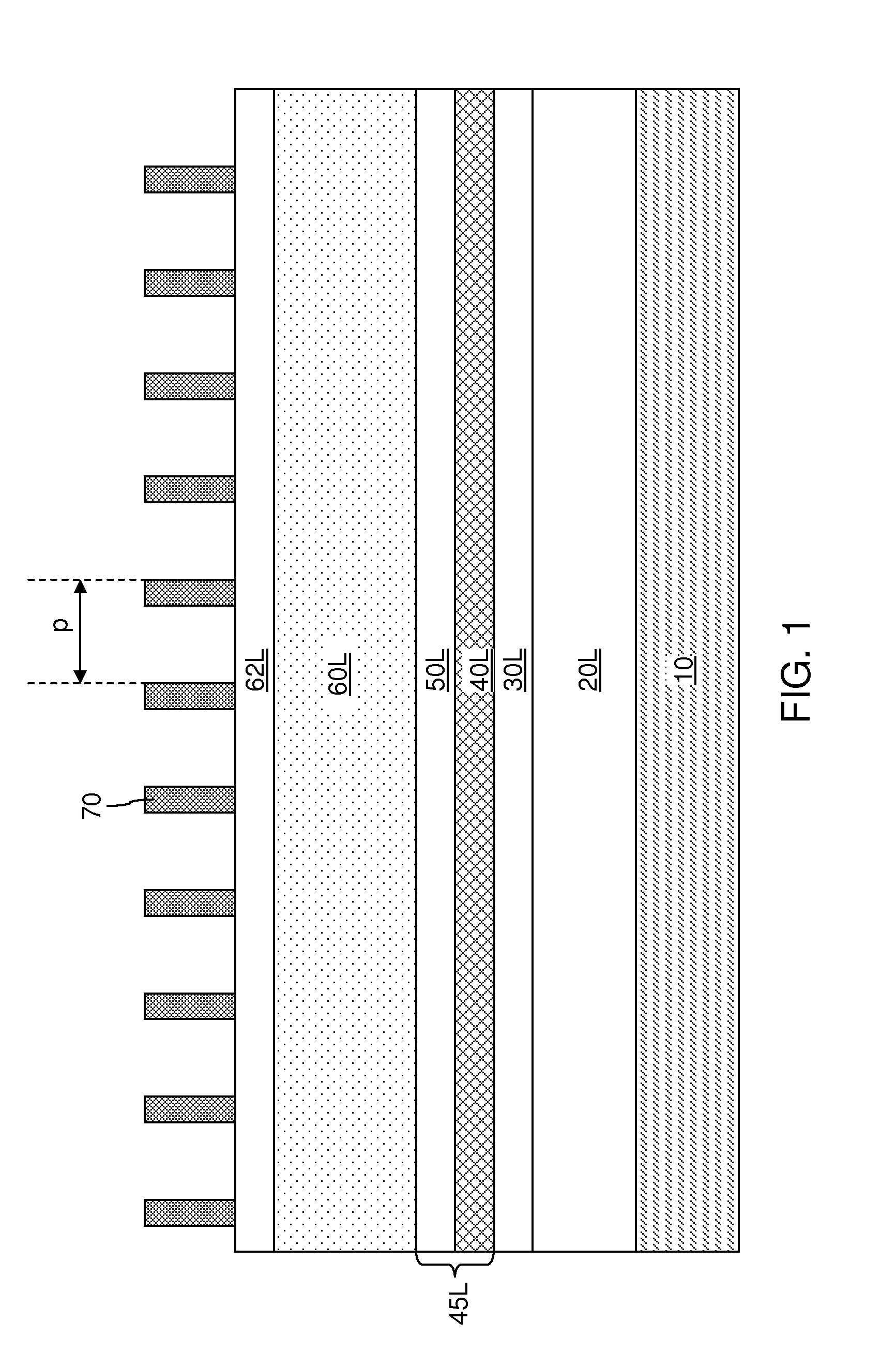

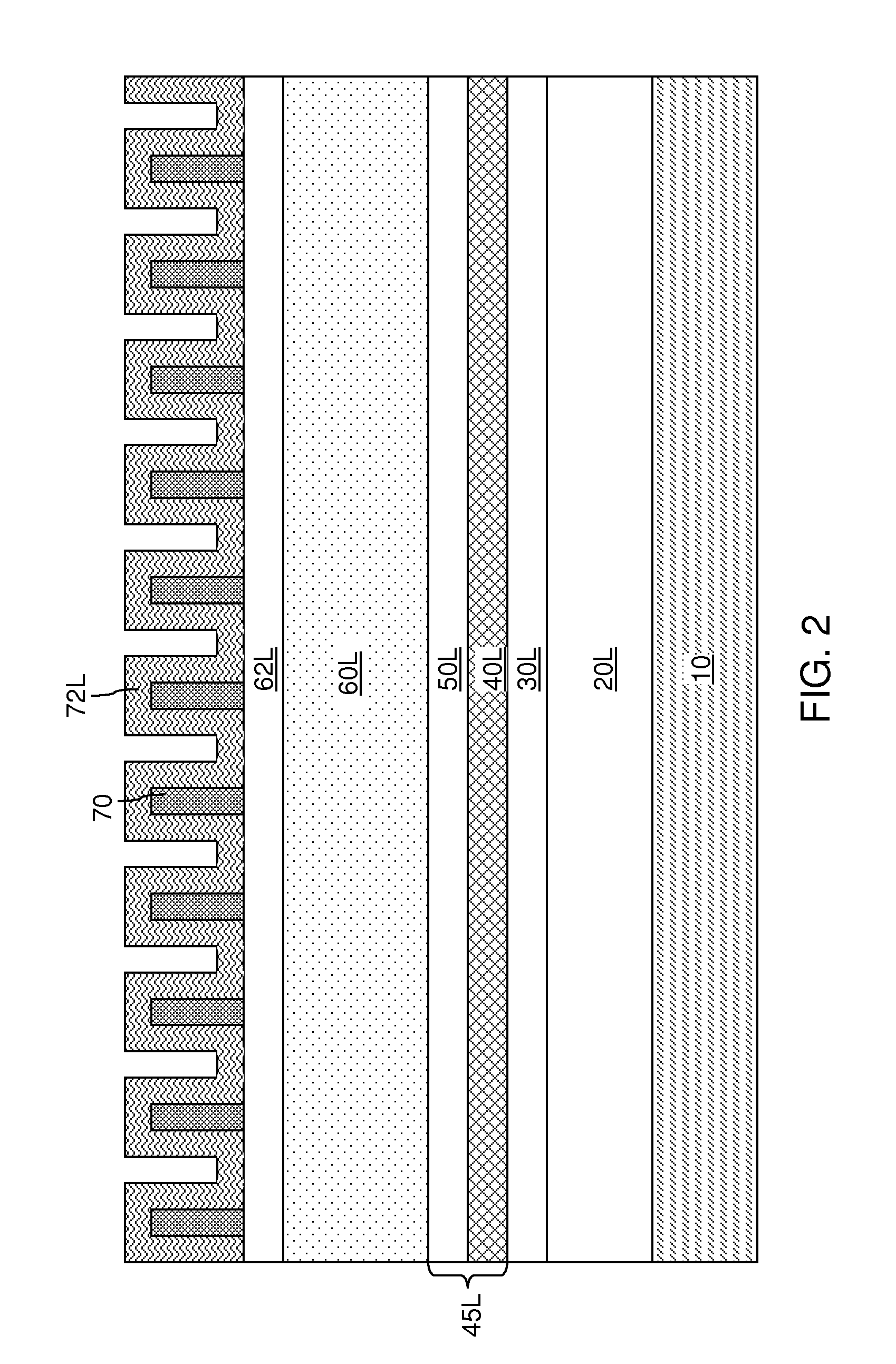

[0038]FIG. 1 is a vertical cross-sectional view of a first exemplary structure after deposition of an underlying material layer, and optional dielectric material layer, a dielectric mask layer, a metallic mask layer, a first organic planarizing layer (OPL), a first antireflective coating (ARC) layer, and mandrel structures according to the present disclosure.

[0039]Referring to FIG. 1, a first exemplary structure according to a first embodiment of the present disclosure includes a substrate 10 and a material stack formed thereupon. The substrate 10 can include a semiconductor substrate having semiconductor devices (not shown) therein. The semiconductor devices can include, for example, field effect transistors, junction transistors, diodes, resistors, capacitors, inductors, or any other semiconductor device known in the art. The substrate 10 may, or may not, include contact-level dielectric material layers (not shown) and / or interconnect level dielectric material layers (not shown) a...

fourth embodiment

[0126]Referring to FIG. 26, a fourth exemplary structure according to the present disclosure can be derived from the first exemplary structure of FIG. 1 by not forming the mandrel structures 70 and by applying and lithographically patterning a photoresist layer to form a patterned photoresist layer 80 including a first pattern. The patterned photoresist layer 80 can include a set of photoresist material portions.

[0127]The fourth exemplary structure illustrated in FIG. 26 is a lithographic structure, which includes the underlying material layer 20L located on the substrate 10; at least one mask layer 45L including at least one of a dielectric material and a metallic material and located over the underlying material layer 20L; the first organic planarizing layer (OPL) 60L located over the at least one mask layer 45L; the first antireflective coating (ARC) layer 62L located on the first OPL 60L; and the patterned structure of the patterned photoresist layer 80 located over the first AR...

fifth embodiment

[0129]Referring to FIG. 27, a fifth exemplary structure according to the present disclosure can be derived from the second exemplary structure of FIG. 18 by not forming the mandrel structures 70 and by applying and lithographically patterning a photoresist layer to form a patterned photoresist layer 80 including a first pattern. The patterned photoresist layer 80 can include a set of photoresist material portions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com